Nickel-cobalt-iron-gallium hyperelastic alloy material and preparation method thereof

A technology of superelastic alloys and alloy materials, applied in the field of alloys, can solve the problems of high internal friction and high cost of titanium-nickel alloys, and achieve the effects of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

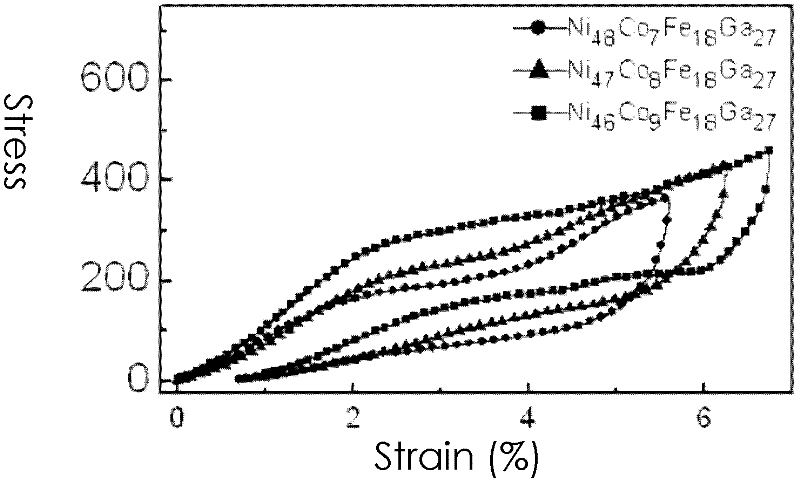

Embodiment 1

[0025] Step 1: Smelting suction casting

[0026] Select nickel with a purity of 99.9%, cobalt with a purity of 99.99%, gallium with a purity of 99.99%, and iron with a purity of 99.9%, according to Ni 55-x co x Fe 18 Ga 27 , x = 7-9 atomic percentage content ratio, using an electronic balance to be accurate to 0.1 mg ingredients; -4 Pa, then filled with argon, repeated smelting for 5 times to make button-shaped materials; The water-cooled mold is quickly suction-cast into a rod-shaped nickel-cobalt-iron-gallium alloy with a diameter (Φ) of 4mm.

[0027] Step 2: Annealing

[0028] The rod-shaped nickel-cobalt-iron-gallium alloys were respectively sealed in test tubes and evacuated to 5×10 -5 Pa, at 1000°C, keep it warm for 72 hours, and then slowly cool to room temperature with the furnace to get Ni 55-x co x Fe 18 Ga 27 The superelastic alloy material, where x=7-9, is a nickel-cobalt-iron-gallium superelastic alloy material described in the present invention.

[002...

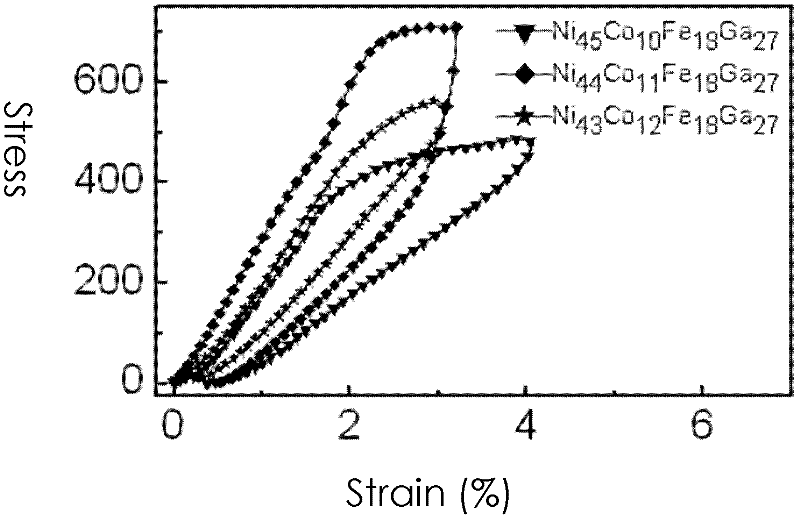

Embodiment 2

[0032] Step 1: Smelting suction casting

[0033] Select nickel with a purity of 99.9%, cobalt with a purity of 99.99%, gallium with a purity of 99.99%, and iron with a purity of 99.9%. 55-x co x Fe 18 Ga 27 , x = 10-12 atomic percentage content ratio, using an electronic balance to be accurate to 0.1 mg of ingredients; -4 Pa, then filled with argon, repeated smelting for 5 times to make button-shaped materials; The water-cooled mold is quickly suction-cast into a rod-shaped nickel-cobalt-iron-gallium alloy with a diameter of 4mm.

[0034] Step 2: Annealing

[0035] The rod-shaped nickel-cobalt-iron-gallium alloys were respectively sealed in test tubes and evacuated to 5×10 -5 Pa, at 1000°C, keep it warm for 72 hours, and then slowly cool to room temperature with the furnace to get Ni 55-x co x Fe 18 Ga 27 The superelastic alloy material, where x=10-12, is a nickel-cobalt-iron-gallium superelastic alloy material described in the present invention.

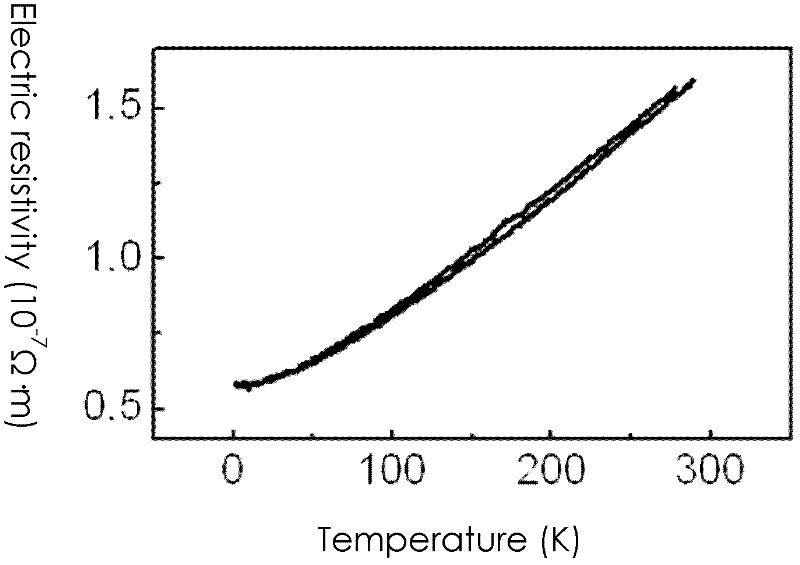

[0036] In the Ni ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com