Patents

Literature

125results about How to "Shorter payback time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

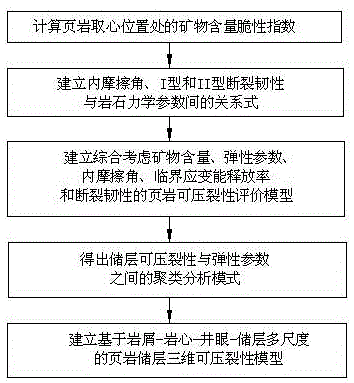

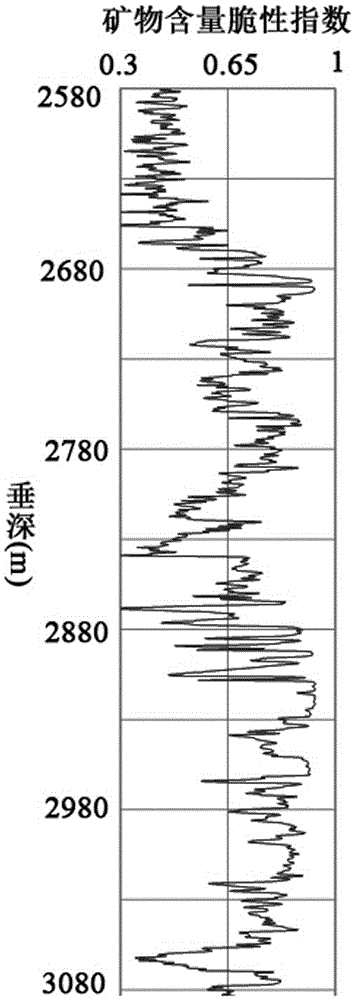

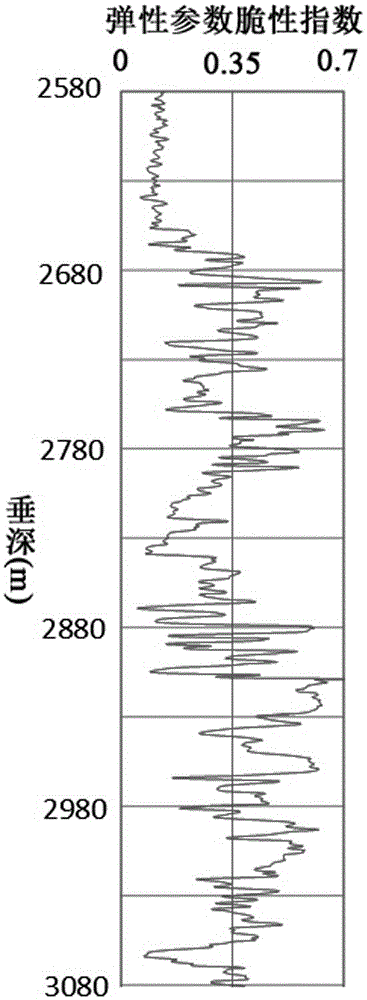

Debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method

ActiveCN105156103ALarge capacityQuantification of fracabilityBorehole/well accessoriesType fractureWell placement

The invention relates to a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method. The method comprises the steps of: (S1) calculating mineral content brittleness indexes in a shale coring position; (S2) building relations among an internal friction angle, I type and II type fracture toughness and rock mechanical parameters; (S3) building shale fracturing evaluation models comprehensively considering a mineral content, elastic parameters, the internal friction angle, a critical strain energy release rate and the rapture toughness; (S4) applying a support vector machine algorithm to obtain a cluster analysis mode between a reservoir fracturing performance and the elastic parameters; and (S5) applying the cluster analysis mode and a reservoir three-dimensional elastic parameter data body to obtain a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing model. The method can be applied to obtain the fracturing performance of any space position in a shale reservoir, so that the well position selection blindness is prevented, and the fracturing modification effect and the after-pressing yield are improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

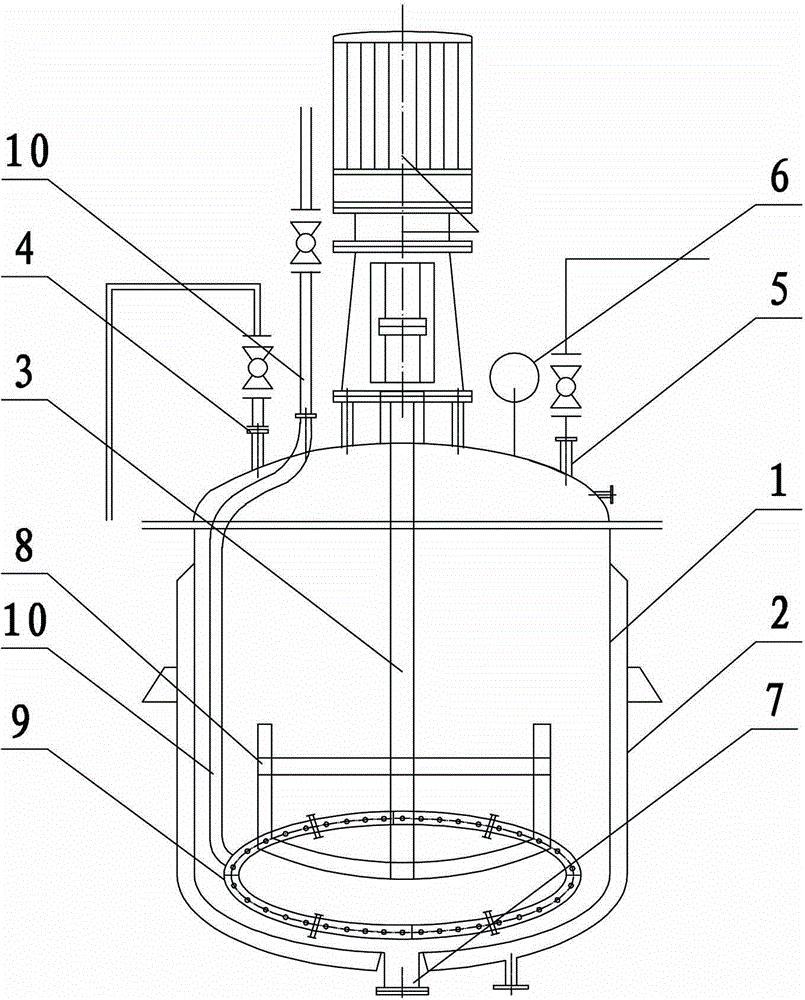

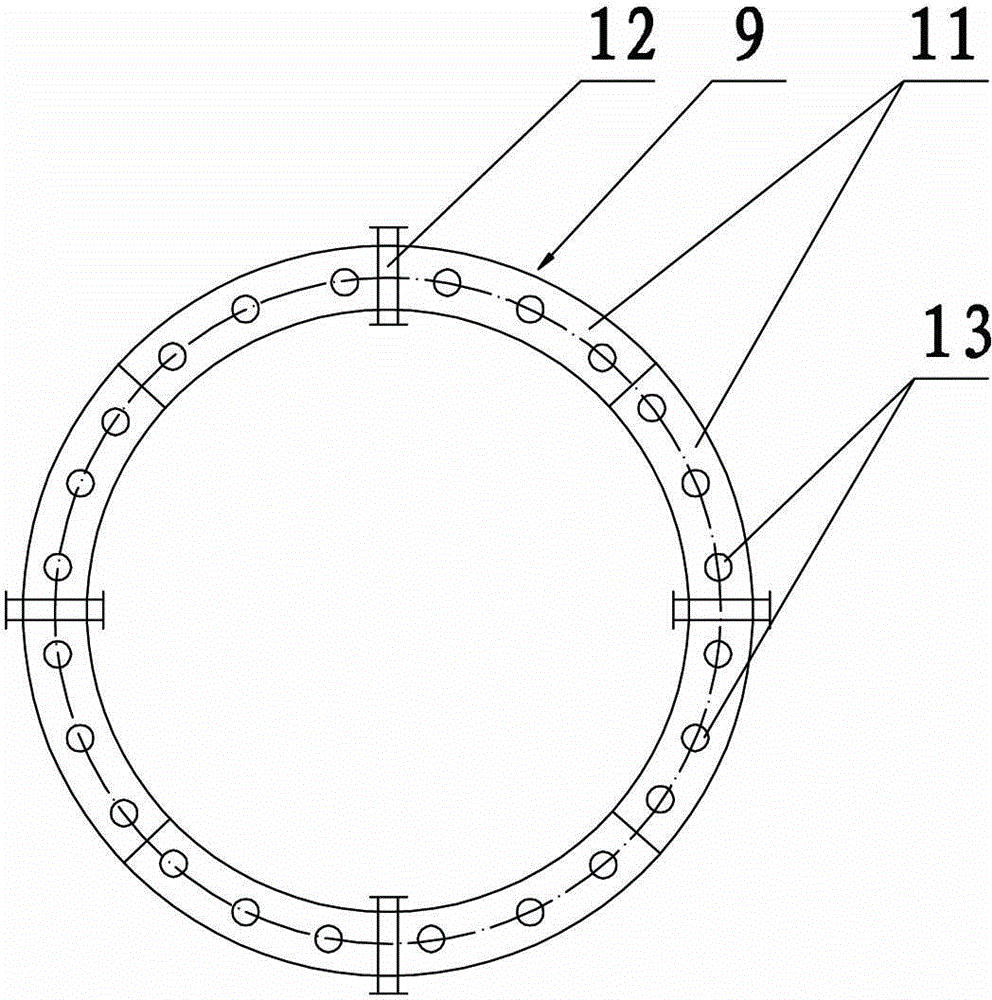

Ammonification reaction vessel for rapidly recycling ammonia gas

InactiveCN105327665AEvenly distributedShorten exhaust timeChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesNitrogenMechanical equipment

The invention relates to the field of chemical mechanical equipment, and provides an ammonification reaction vessel for rapidly recycling ammonia gas. The ammonification reaction vessel comprises a reaction vessel body, a stirring device is arranged in the reaction vessel, a feed inlet is arranged at the top of the reaction vessel, a discharge port is arranged at the bottom of the reaction vessel; a distance between the bottom of the stirring device of the stirring device and the bottom of the reaction vessel is 10-20cm, a annular gas distributor is installed at the reaction vessel bottom below the stirring device, a nitrogen pipe is installed at the top of the reaction vessel, and the nitrogen pipe extends along an inner wall of the reaction vessel to the vessel bottom and is communicated with gas inlets of the annular gas distributor; the annular gas distributor is composed of four arc pipes which are connected end to end, a central section of each arc pipe is installed at the reaction vessel bottom by a clamp, and an upper part of each arc pipe is opened with several uniformly distributed small holes; the ammonification reaction vessel has the advantages of simple structure, design benefit, and installation and maintenance convenience, substantially increases recovery speed of ammonia gas after reaction is carried out in the ammonification reaction vessel, reduces usage amount of nitrogen, and improves production power of the equipment.

Owner:HUBEI BIOCHEM PHARMA TECH

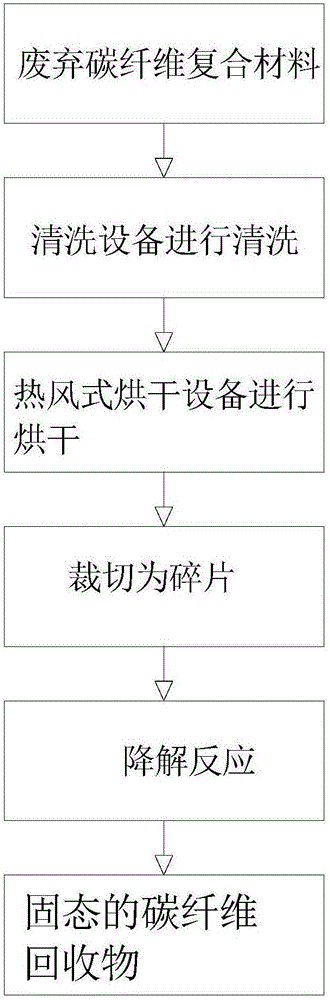

Carbon fiber composite material recovery method

InactiveCN105199139AHigh recovery rateImprove recycling efficiencyPlastic recyclingRecovery methodMicrowave oven

The invention relates to a carbon fiber composite material recovery method. The method comprises the following steps: putting a waste carbon fiber composite material in stirring cleaning equipment to be cleaned, spreading fragments on a tray, putting the tray in a microwave oven, carrying out radiation heating treatment on the carbon fiber composite material fragments in the tray, filling an inert gas in the microwave oven to protect the carbon fiber composite material when the carbon fiber composite material undergoes degradation reaction in the microwave oven and obtaining a solid recovered carbon fiber material after degradation of the carbon fiber composite material is completed. The method has the beneficial effects that the impurities on the surface of the carbon fiber composite material can be removed and the recovery rate of the carbon fibers in the carbon fiber composite material can be increased by cleaning the carbon fiber composite material; meanwhile, the degradation reaction efficiency of the carbon fiber composite material in the microwave oven is further improved by cutting the carbon fiber composite material into the fragments; and the recovery rate of the carbon fibers can be greatly increased, the recovery time can be shortened and waste of the carbon fiber material can be avoided by adopting the recovery method.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Safe and fast driving method for large-section open-off cut time-by-time tunneling

InactiveCN102505942ARealize turning and self-adjusting machineReduce exposure to coal dustUnderground miningSurface miningThermodynamicsEngineering

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

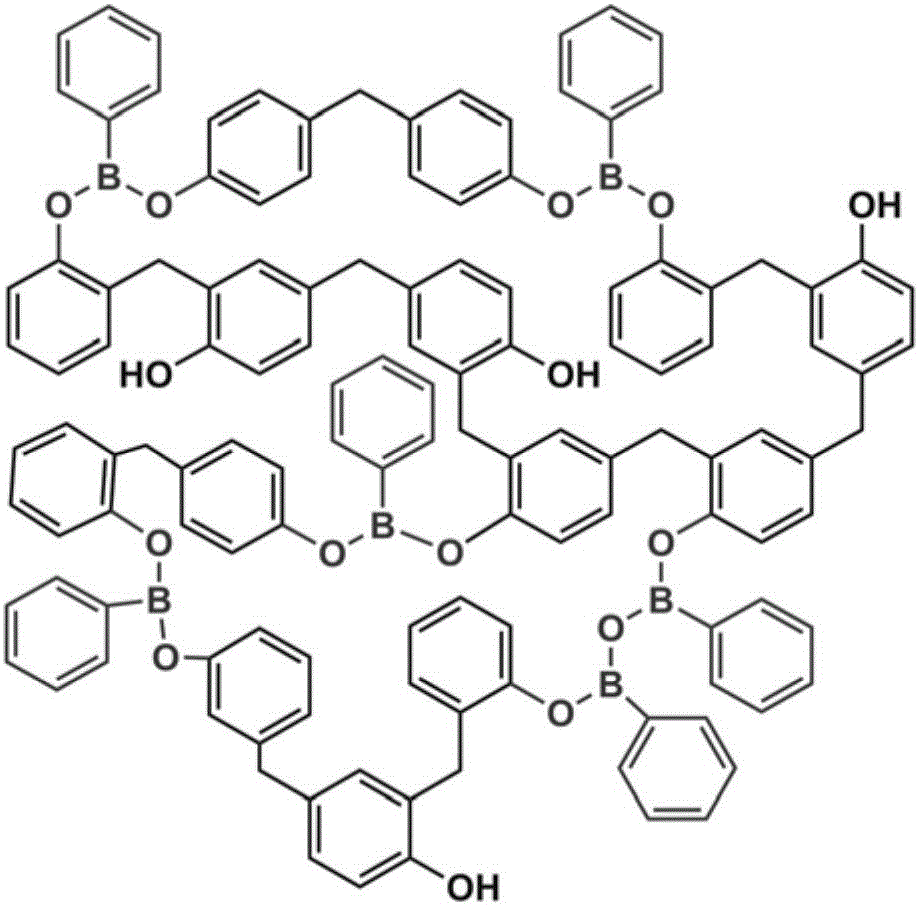

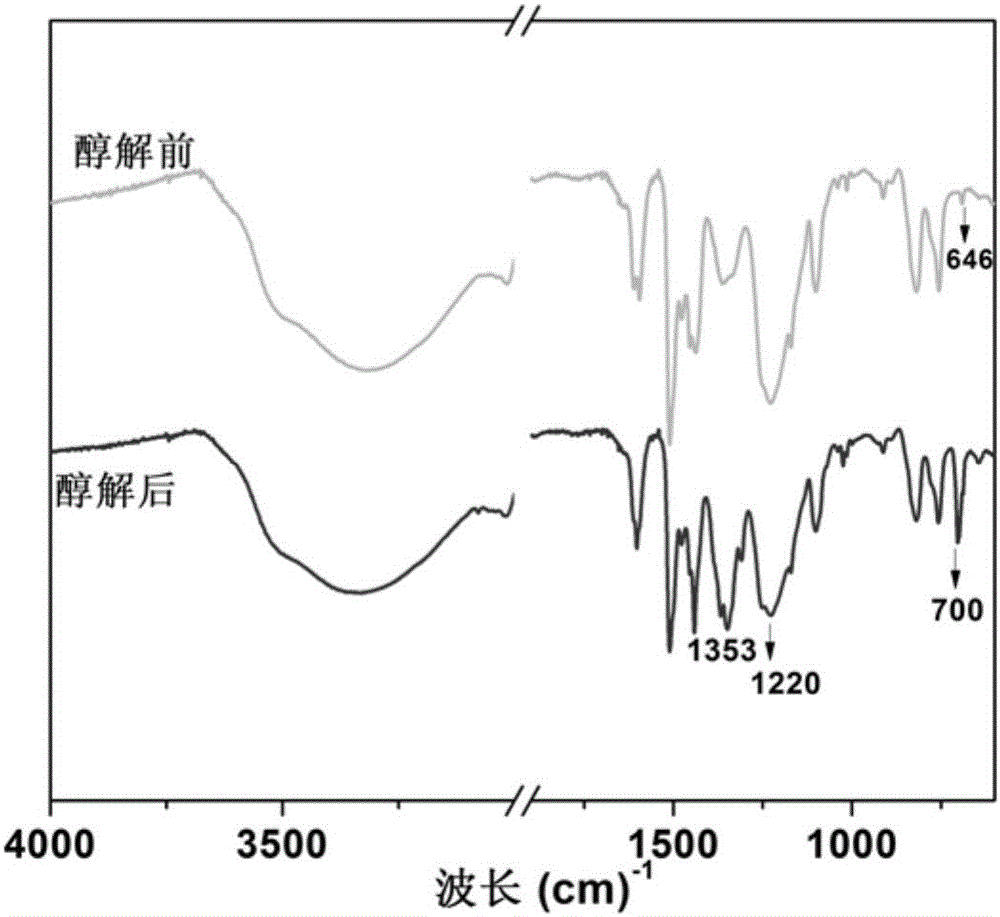

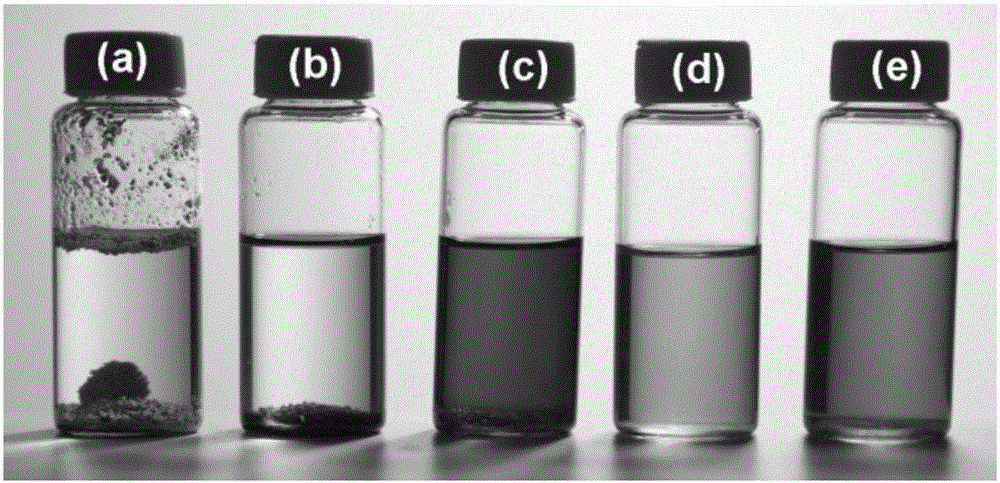

Preparation method of room-temperature regenerated phenolic resin and recycling technology and application thereof

ActiveCN106750064ALow softening temperatureReduce melt viscosityPlastic recyclingOrganic solventAlcohol

The invention relates to a preparation method of room-temperature regenerated phenolic resin and a recycling technology and application thereof. The preparation method comprises the following steps of according to parts by mass, melting and blending 100 parts of thermoplastic phenolic resin and 18.4 to 55 parts of boric acid compound at the temperature of 60 to 100 DEG C, so as to obtain boron-containing thermoplastic phenolic resin; or, dissolving 100 parts of thermoplastic phenolic resin and 20 to 50 parts of boric acid compound into an organic solvent with low boiling point at the temperature of 40 to 60 DEG C, so as to obtain the boron-containing thermoplastic phenolic resin; curing, so as to obtain the room-temperature regenerated phenolic resin. The preparation method has the advantages that the preparation technology of the resin is simple; the resin is dissolved into the mixing solvent of ethyl alcohol and water at room temperature, so that the resin can be recycled; the resin can be used for preparing the recyclable fiber reinforced boron-containing thermoplastic phenolic resin-based composite material. The prepared boron-containing thermoplastic phenolic resin has the advantages that the function of arylboronic acid ester structure promoting the heat-resistant property of the thermoplastic phenolic resin is fully realized, and the technology of the resin and the mechanical property of the composite material can be simultaneously realized.

Owner:XI AN JIAOTONG UNIV +1

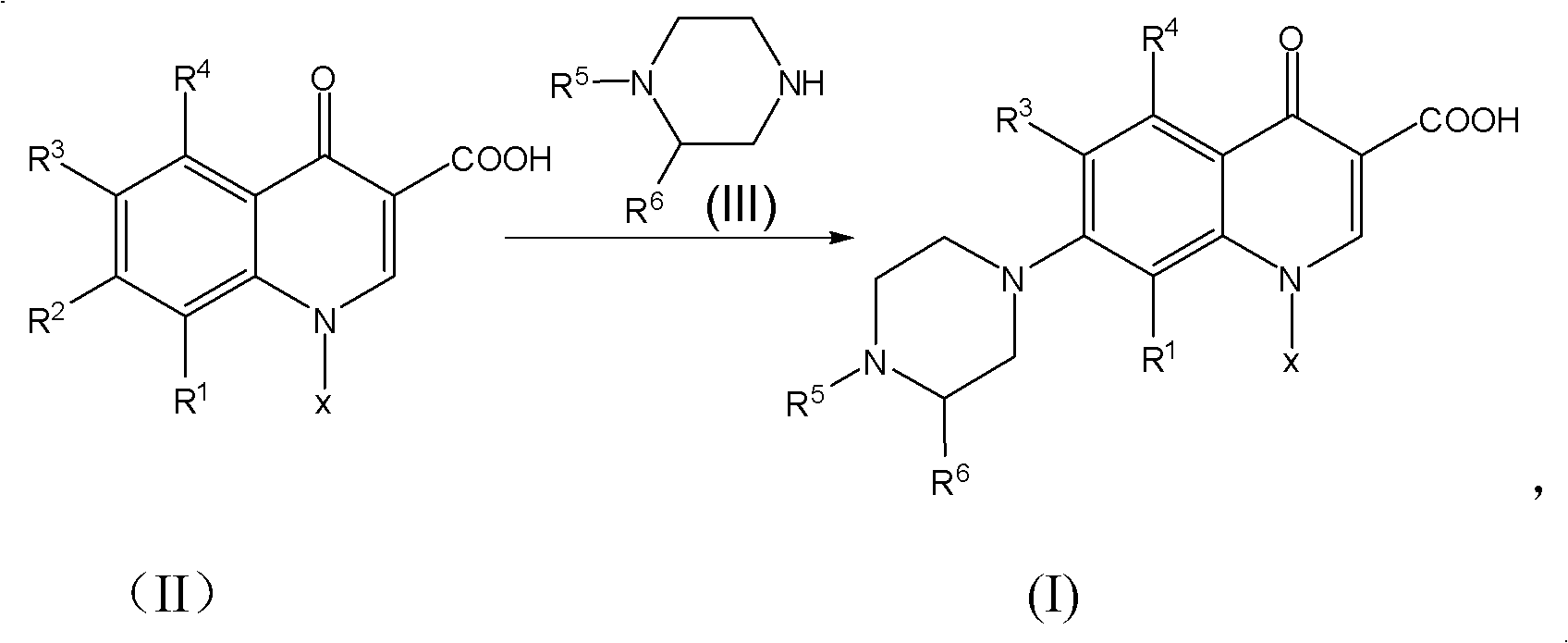

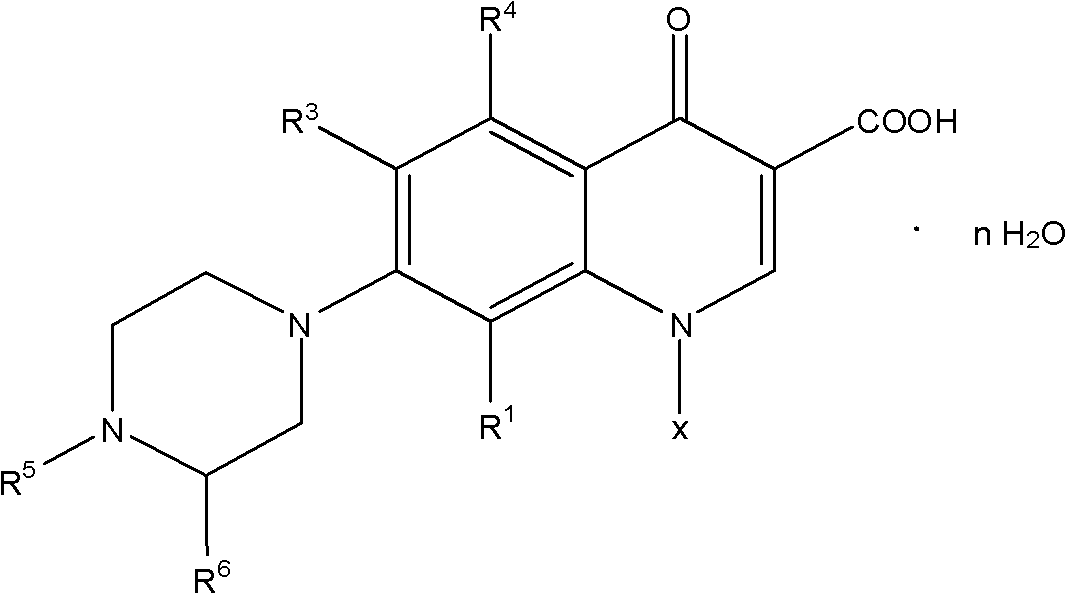

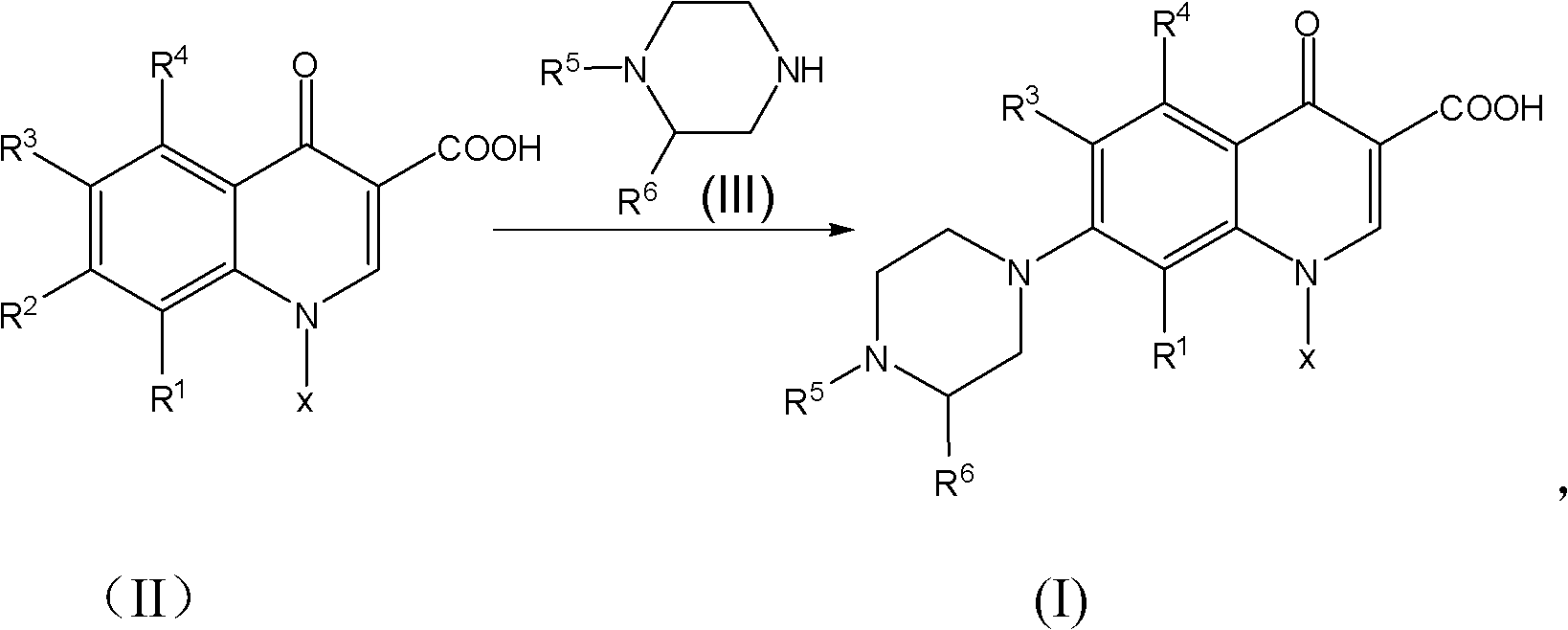

Method for synthesizing quinolone medicaments

InactiveCN101781313ASolve the environmental odor problemRealize cleaner productionOrganic chemistryCarbonyldiimidazoleCarboxylate

The invention discloses a method for preparing quinolone medicaments. The conventional methods using organic solvents with a high boiling pint and a large polarity, adopting other solid alkali materials except reaction materials or using other liquid alkali materials except the reaction materials have obvious defects. The method of the invention adopts a technical scheme that: quinolone compounds are prepared by a piperazidine reduction of quinolone carboxylate nuclear parent and piperazidine derivates in water; the piperazidine reduction is completed in the presence of a catalyst which may be one or a mixture of more than two of cerous chloride heptahydrate, N,N-carbonyldiimidazole, 4-dimethylamino pyridine, tetrabutylammonium bromide, benzyl triethylammonium chloride and tetrabutyl ammonium hydroxide. The method for preparing the quinolone medicaments radically solves the problems of terrible smell, realizes clean production, avoids using the other alkali substances except the reaction materials as an acid-binding agent and overcomes the defects of the prior art.

Owner:ZHEJIANG JINGXIN PHARMA +1

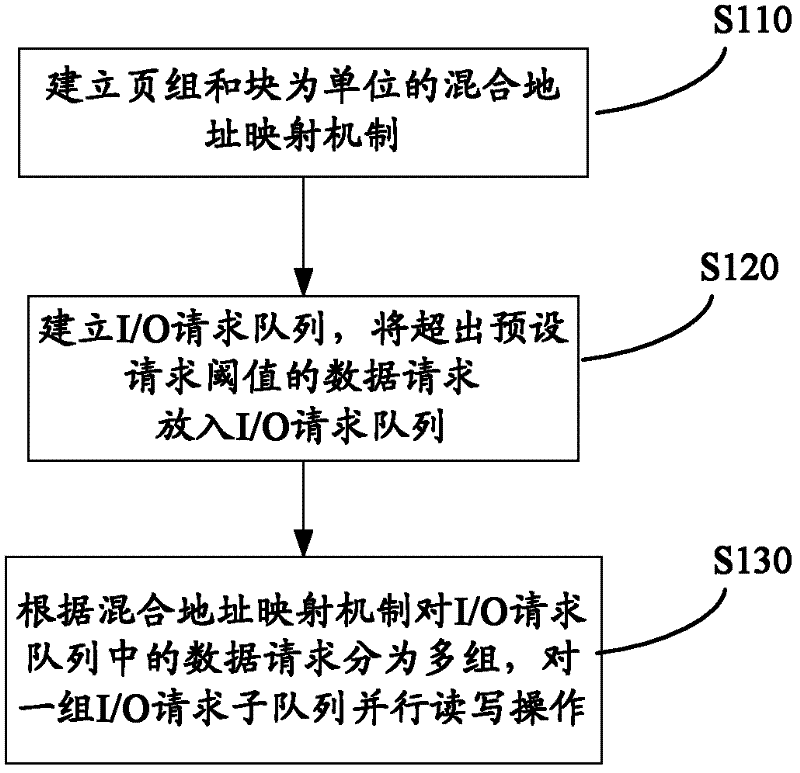

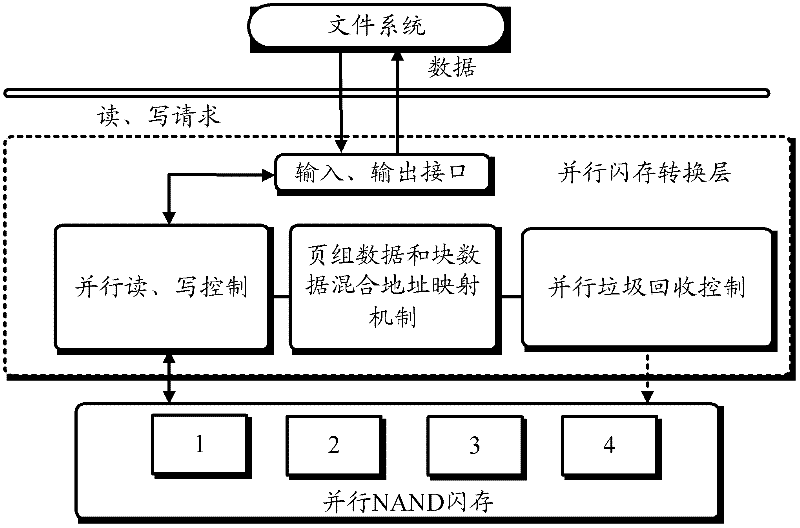

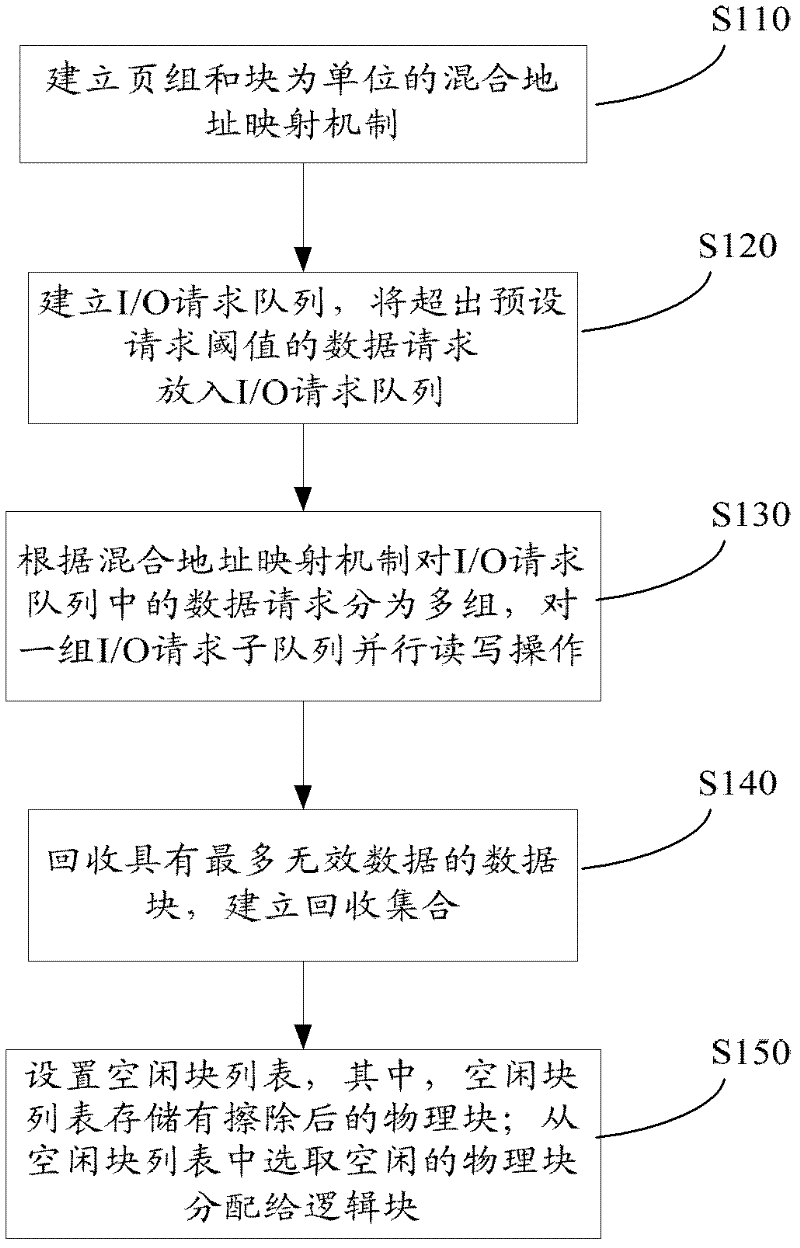

Method for implementing parallel-flash translation layer and parallel-flash translation layer system

ActiveCN102609218AShorter payback timeSave memory spaceInput/output to record carriersMemory adressing/allocation/relocationFile systemAddress mapping

The invention discloses a parallel-flash layer translating method, which comprises the following steps: establishing a mixed address mapping mechanism which makes a page group and a block as an unit, wherein the page group can be divided into a logic page group and a physical page group, the block can be divided into a logic block and a physical block; when the quantity of I / O requests sent by a file system is larger than a predetermined request threshold value, establishing an I / O request queue and putting the I / O requests which are beyond the predetermined request threshold value in the I / O request queue; dividing the I / O requests of the I / O request queue into a plurality of groups of I / O request sub-queues according to the mixed address mapping mechanism; and carrying out parallel reading-writing operation to each group of I / O request sub-queues, wherein each group of the I / O request sub-queues comprise a plurality of I / O requests and the plurality of I / O requests can operate parallelly. The method utilizes excellent parallel-flash feature completely through the parallel reading-writing operation; writing-in and erasing time is reduced; thus, complexity is reduced; and high performance is obtained. The invention also discloses a parallel-flash translation layer system.

Owner:TSINGHUA UNIV

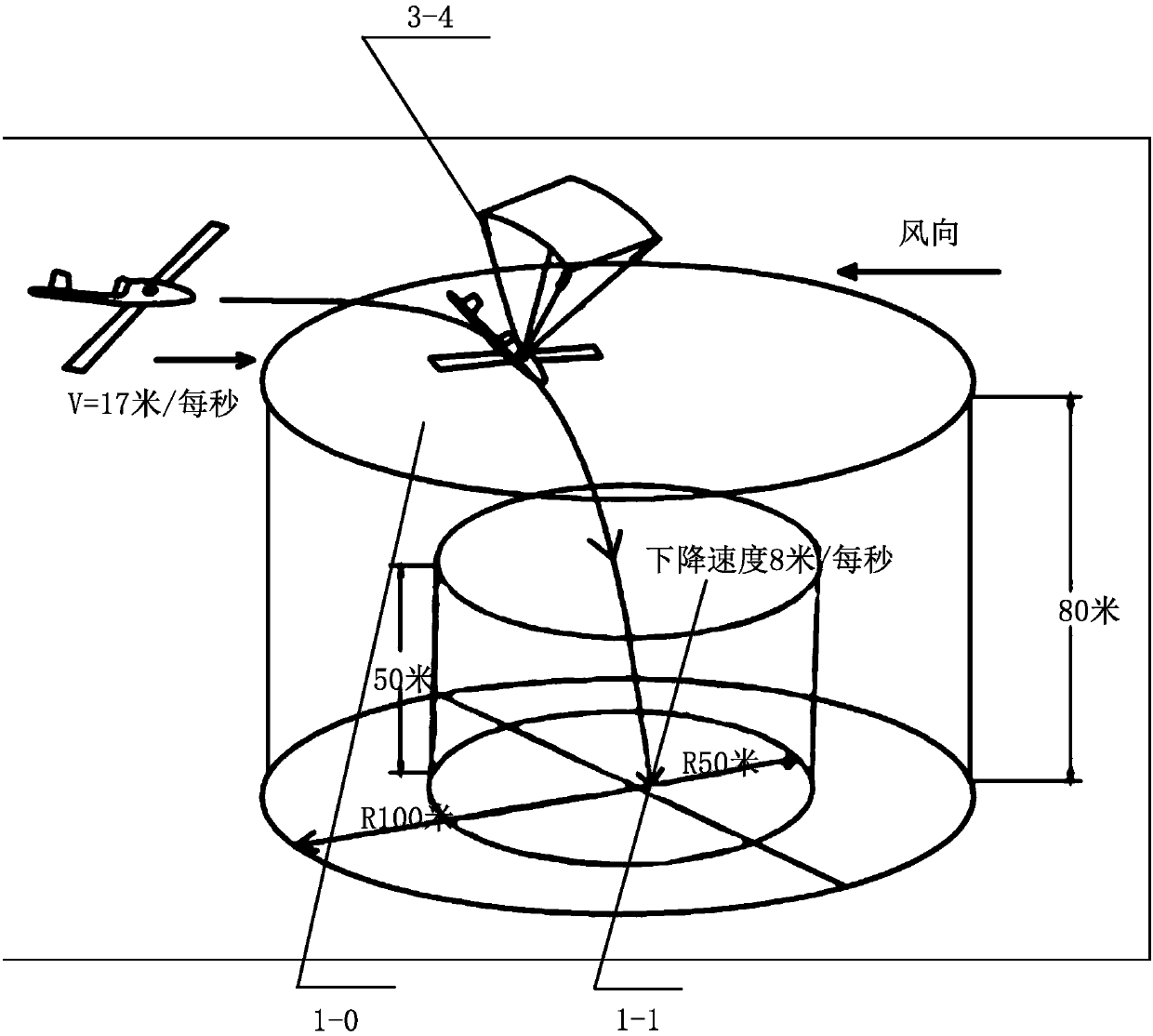

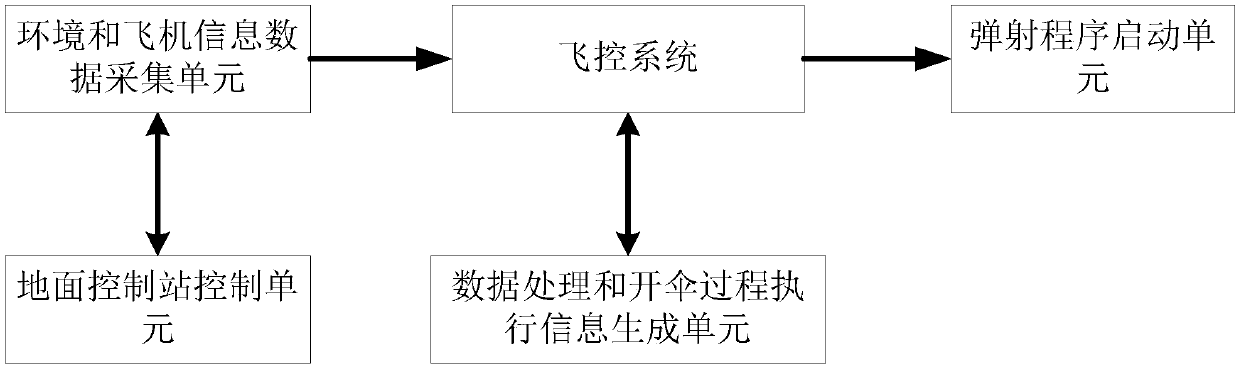

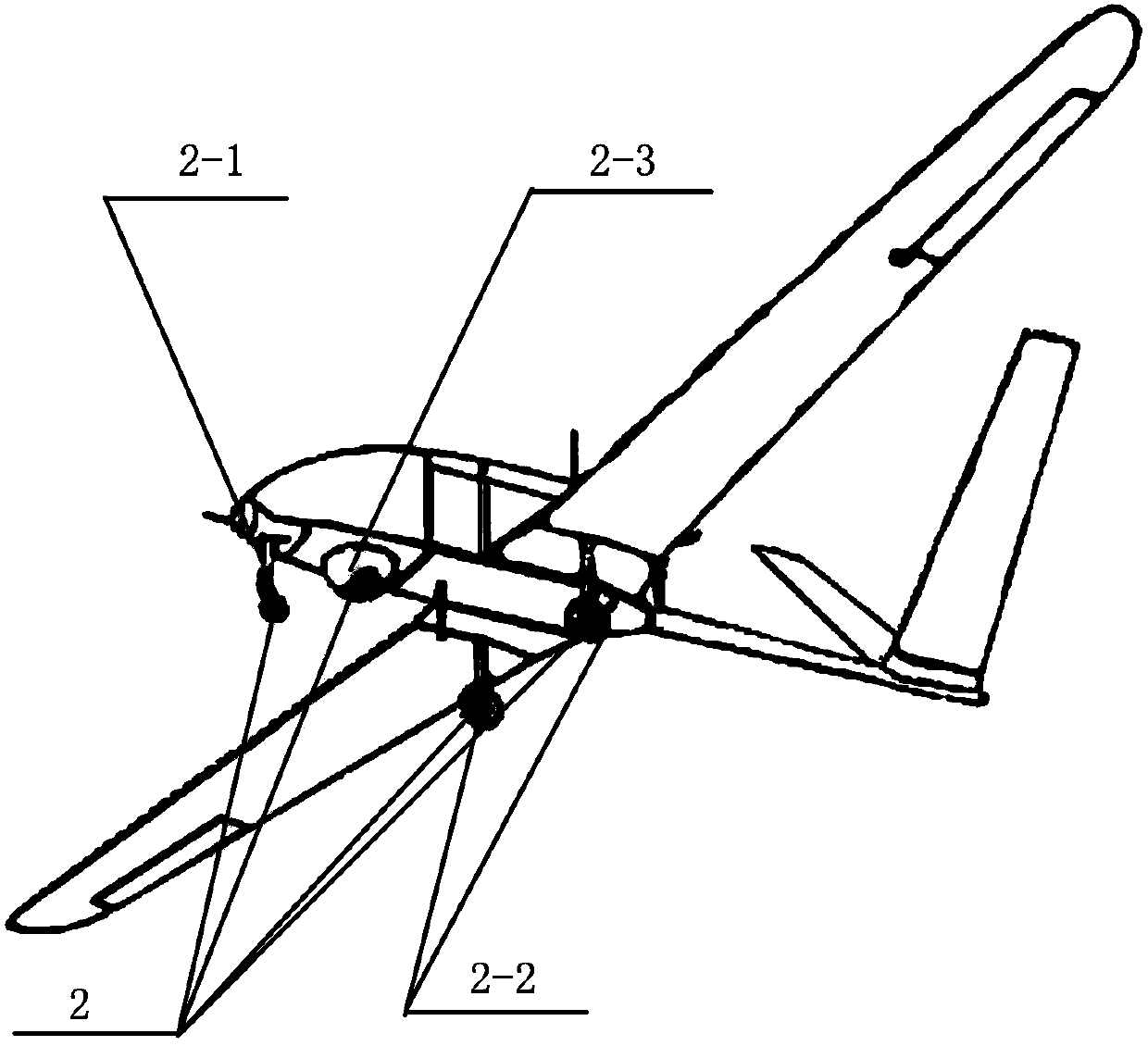

High-speed parachute landing system and method for medium-and-small-sized unmanned aerial vehicles and ejection chute

The invention discloses a high-speed parachute landing system and method for medium-and-small-sized unmanned aerial vehicles and an ejection chute. The high-speed parachute landing system and method for medium-and-small-sized unmanned aerial vehicles is characterized by comprising a ground control station control unit, an environment and plane information data acquiring unit, a flight control system, a data processing and executing information generating unit and an ejection sequence starting unit. The method comprises the following steps: setting height parameters and speed parameter of low-altitude and low-speed parachute opening of an unmanned aerial vehicle; flying the unmanned aerial vehicle to the sky above a specific landing region and receiving a ground station command; determiningthe landing region and entering the region according to a specific path; and starting a control system to open a parachute by ejection and landing. The ejection chute comprises a parachute and ejection gas cylinder guns which are mounted at four corners of the parachute. By low-altitude parachute opening, vertical landing time of the unmanned aerial vehicle after the unmanned aerial vehicle enters the landing region is saved by 50%; the whole parachute opening process is automated, a landing preset target point of the unmanned aerial vehicle is positioned accurately; and by parachute openingthrough ejection, the parachute opening speed is increased.

Owner:沈观清 +1

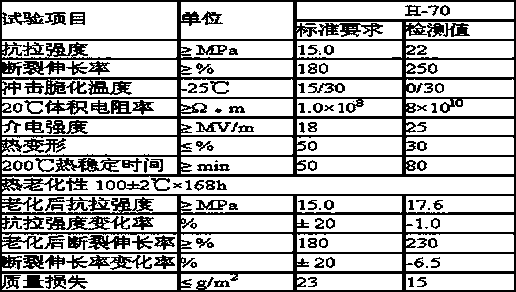

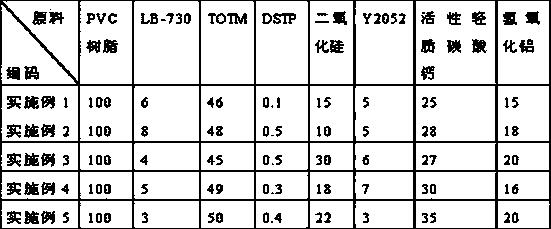

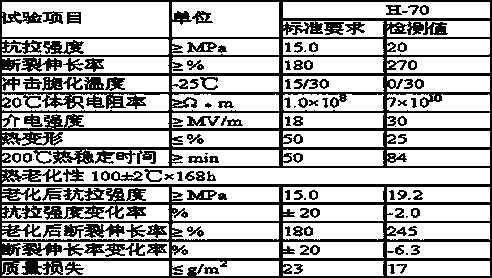

PVC (Polyvinyl Chloride) cable sheath material and preparation method thereof

PendingCN103772846AGood physical and mechanical propertiesMeet environmental protection requirementsPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

The invention belongs to the field of cable materials, and in particular relates to a PVC (Polyvinyl Chloride) cable sheath material which is mainly prepared from the following raw materials by weight: 100 parts of PVC resin, 3-8 parts of shock resistance modifying agent, 45-50 parts of plasticizer, 0.1-0.5 part of antioxidant, 10-30 parts of silicon dioxide, 3-7 parts of thermal stabilizing agent, 25-35 parts of filling agent and 15-20 parts of fire retardant. The PVC cable sheath material provided by the invention is excellent in mechanical physical property and meets the environment-friendly requirements, and meanwhile as silicon dioxide is added into the PVC cable sheath material, the surface of a sheath layer is rough, and the contact area of the sheath layer and an insulating layer can be easily separated as the contact area is reduced.

Owner:苏州德亮材料科技有限公司

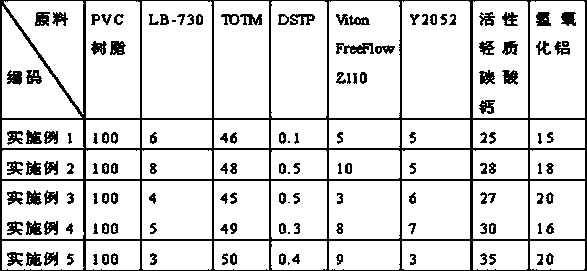

Easily peeled PVC (Polyvinyl Chloride) cable sheath material and preparation method thereof

InactiveCN103665627AGood physical and mechanical propertiesMeet environmental protection requirementsPlastic/resin/waxes insulatorsPolymer sciencePolyvinyl chloride

The invention belongs to the field of cable materials, and in particular relates to an easily peeled PVC (Polyvinyl Chloride) cable sheath material which is mainly prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 3-8 parts of anti-impact modifying agent, 45-50 parts of plasticizing agent, 0.1-0.5 part of antioxidant, 3-10 parts of fluorine lubricant, 3-7 parts of thermal stabilizing agent, 25-35 parts of filling agent and 15-20 parts of flame retardant. The easily peeled PVC cable sheath material provided by the invention is excellent in mechanical physical property, and meanwhile a product meets the environment-friendly requirements; due to addition of the fluorine lubricant, a cable sheath layer has good release properties with an insulating layer, and when being recycled, the insulating layer and the sheath layer can be easily separated.

Owner:苏州德亮材料科技有限公司

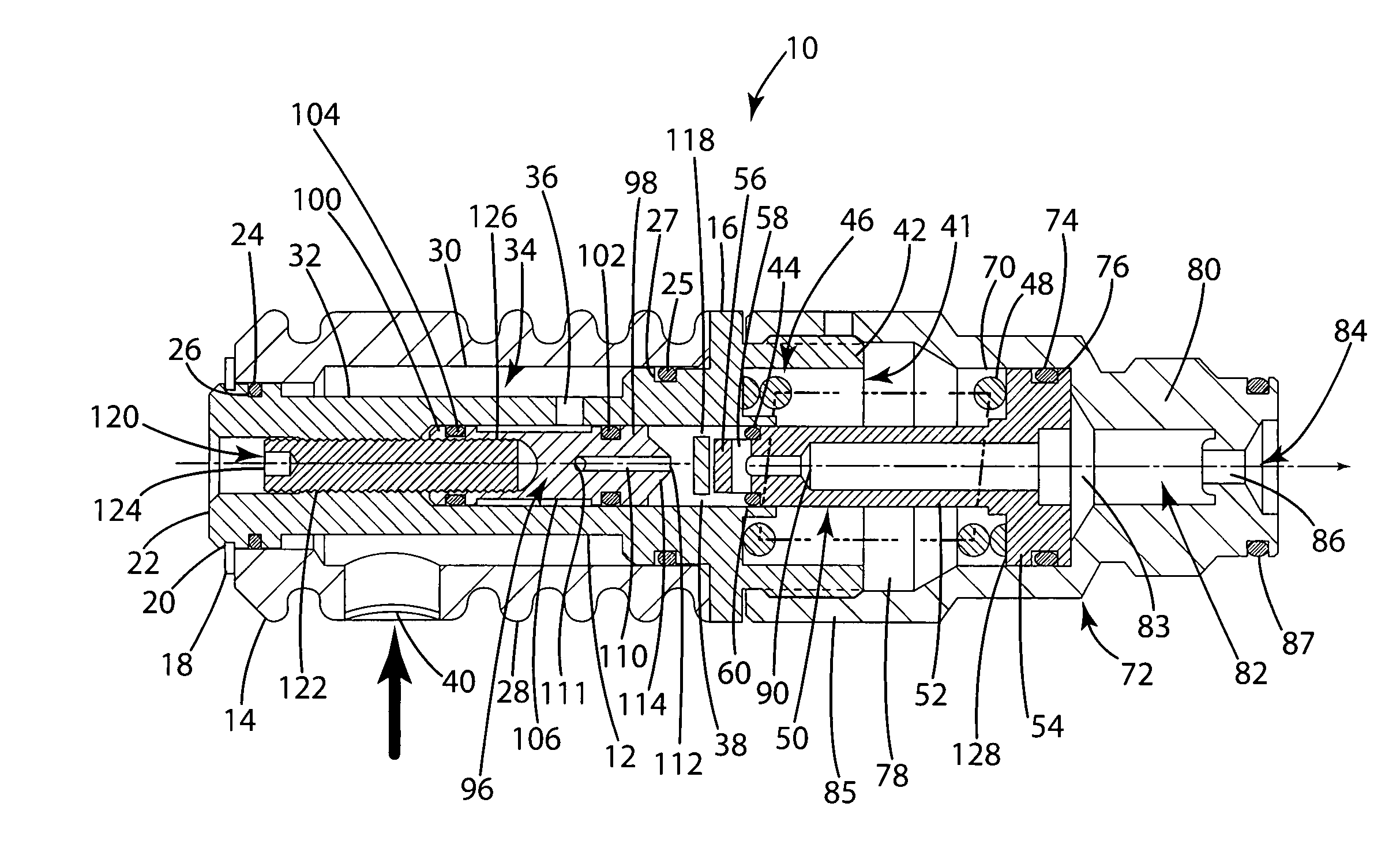

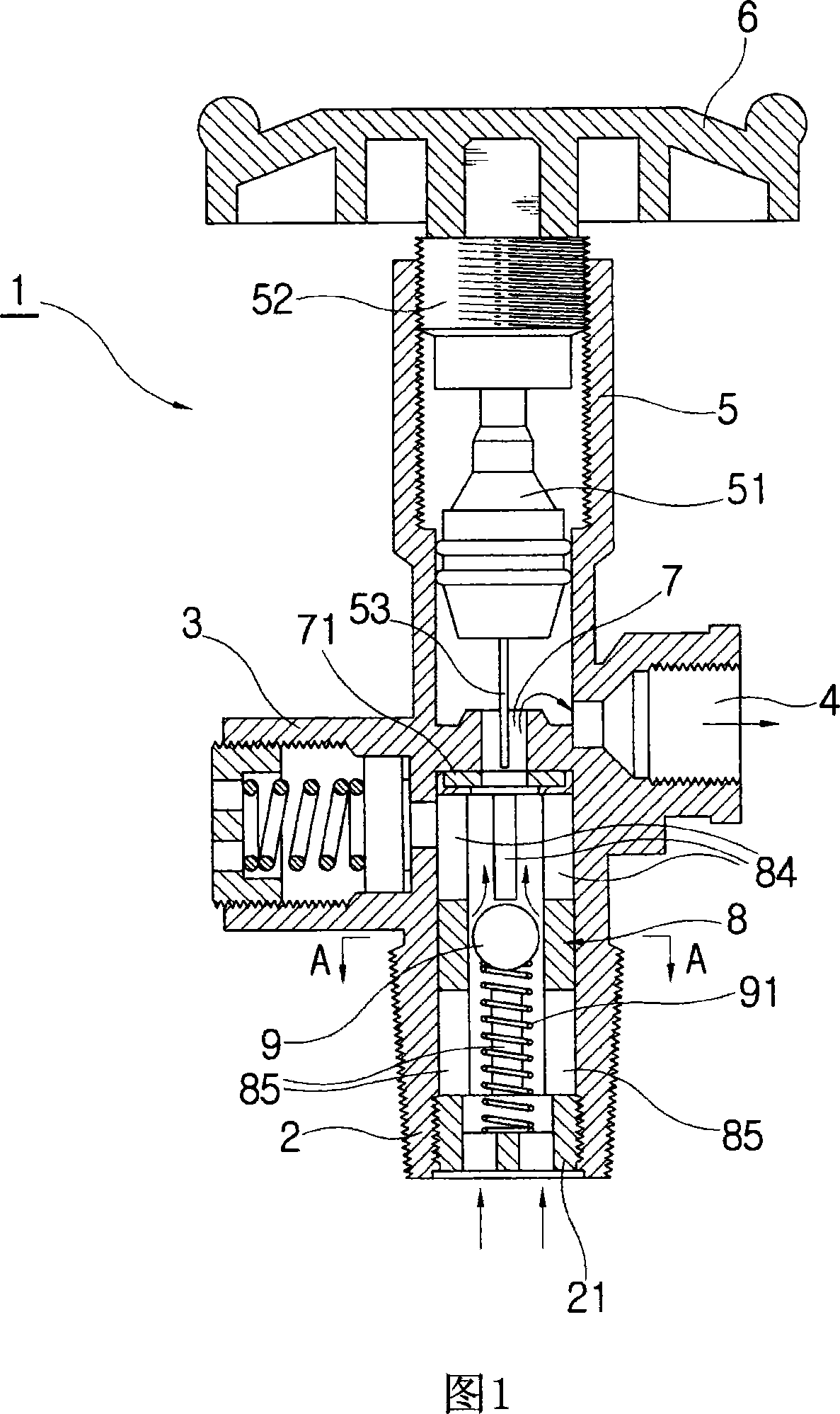

Adjustable pressure regulator

InactiveUS7051755B2Increase outlet pressureShorter payback timeOperating means/releasing devices for valvesValve members for heating/coolingEngineeringExpansion chamber

An adjustable floating seal piston type pressure regulator valve of the type wherein a spring biased piston engages a floating seal in a regulator body valve chamber to open and close a valve seat outlet in the valve chamber. The valve seat comprises a separate member from the regulator body and is adjustably movable in the valve chamber toward and away from the piston, such that movement of the valve seat toward the piston serves to lower a regulated outlet pressure and movement of the valve seat away from the piston serves to increase the regulated outlet pressure. The valve seat member is moved by an adjustment screw that is externally accessible by an adjustment tool. A tubular expansion chamber surrounds the regulator body and provides an enlarged expansion chamber that reduces valve recycle time. Convolutions or ribs in the expansion chamber housing enhance heat through transfer to the valve gases.

Owner:UNIVERSITE CATHOLIQUE DE LOUVAIN +1

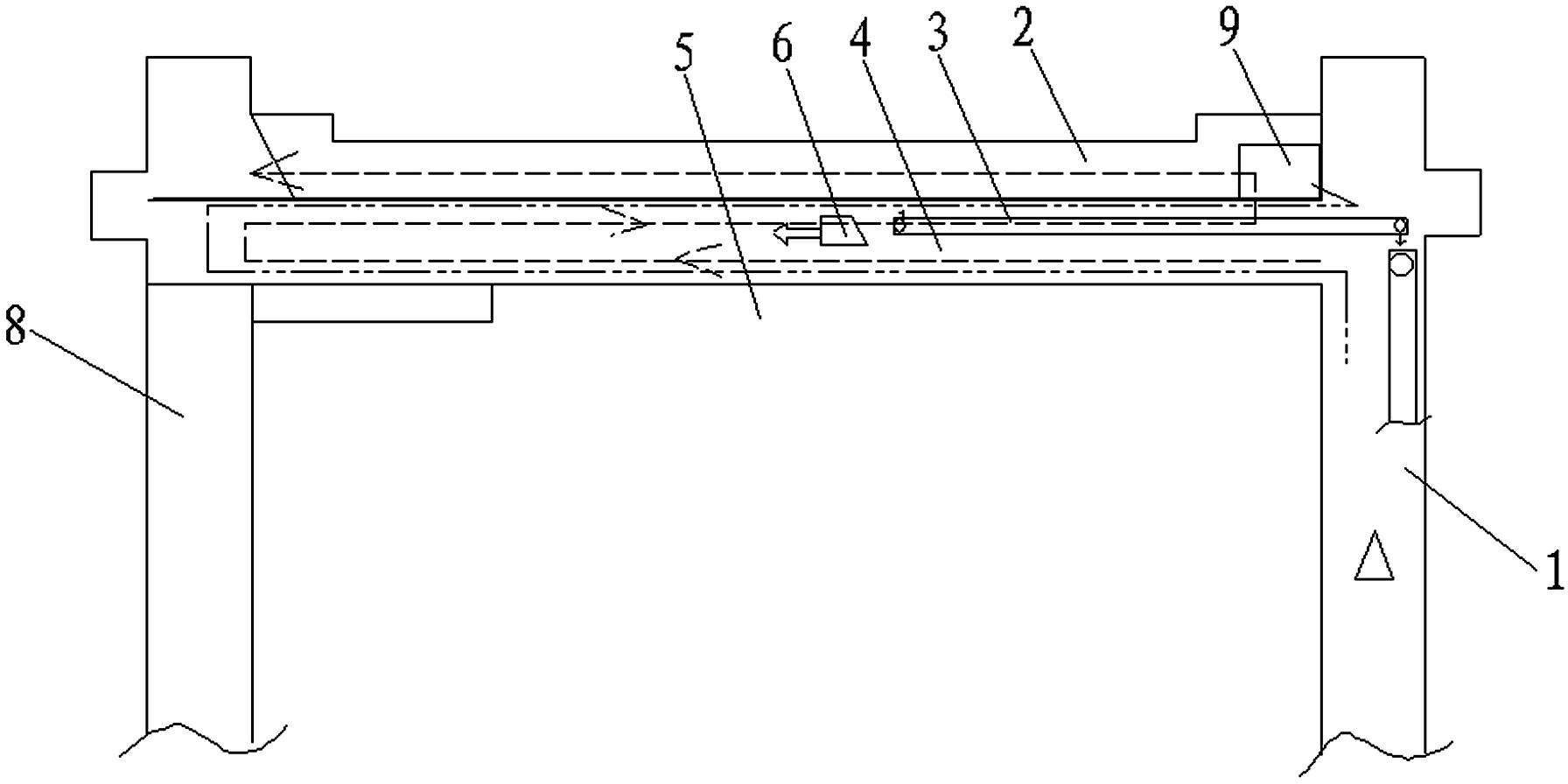

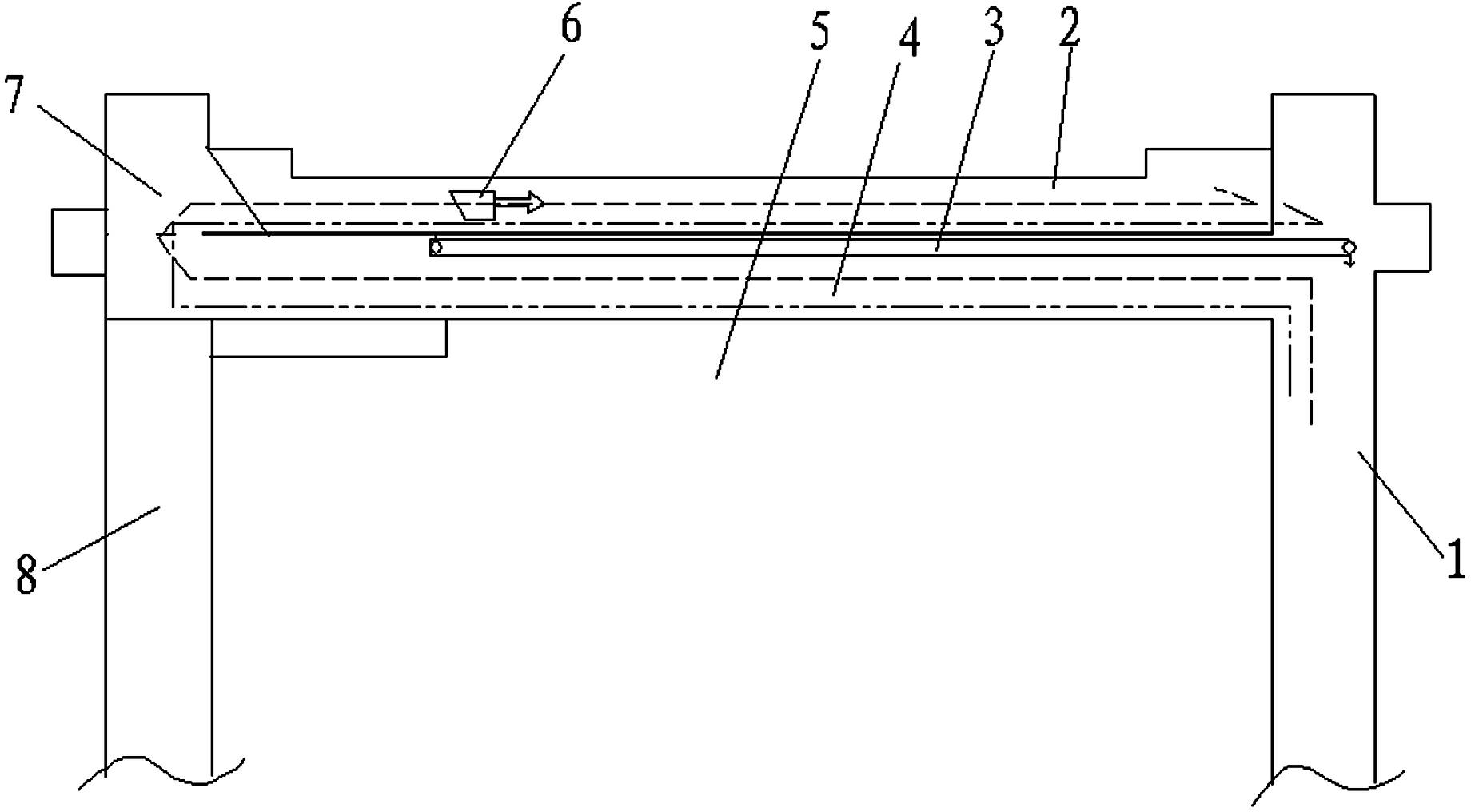

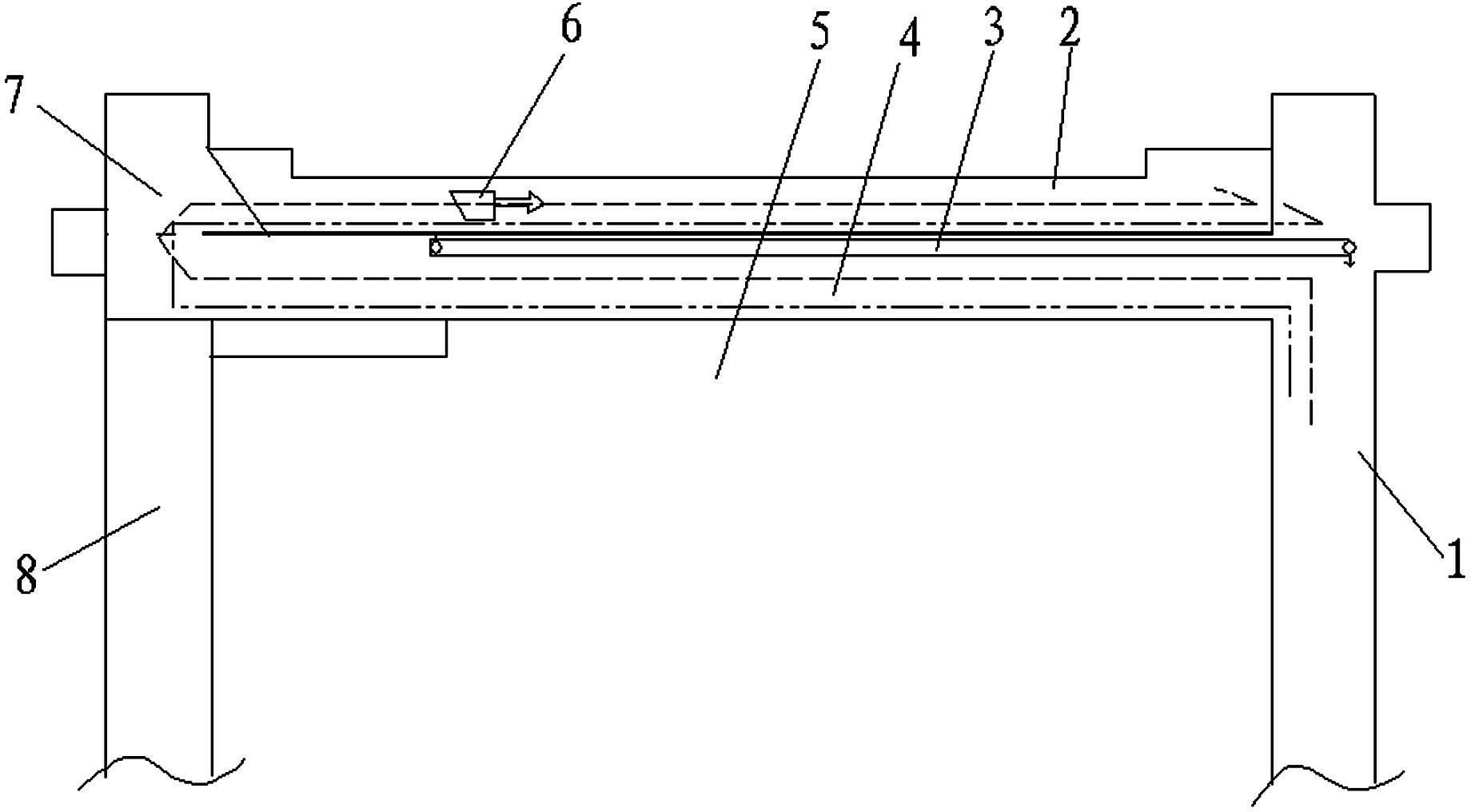

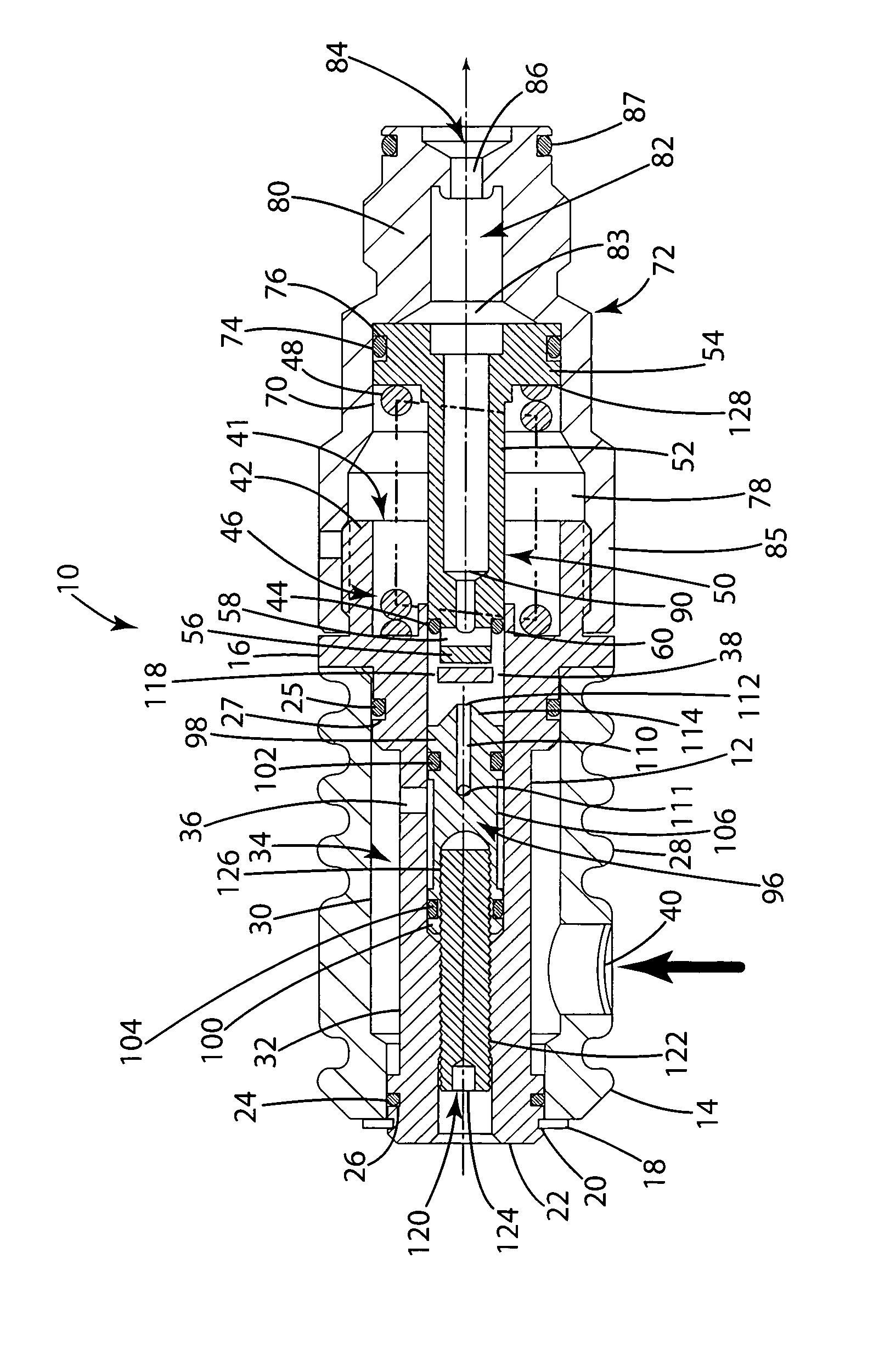

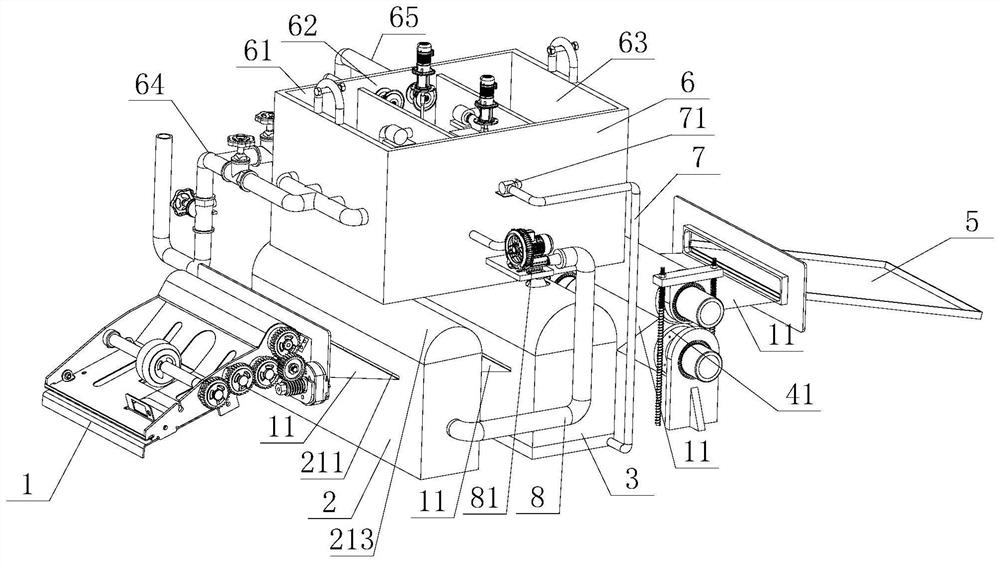

Automatic sorting, residue dumping and cleaning conveyor for tableware

InactiveCN103935744ALow costShorter payback timeTableware washing/rinsing machinesConveyor partsContaminationWaste management

The invention discloses an automatic sorting, residue dumping and cleaning conveyor for tableware. The automatic sorting, residue dumping and cleaning conveyor is provided with a body and feet for supporting the body. A rail is transversely arranged on the table top of the body. A collecting assembly for conducting positioning and alignment on the tableware, a washing assembly for making the tableware individually and continuously moved to washing positions and a recycling assembly for recycling the tableware after the tableware is cleaned are sequentially arranged on the rail from left to right. The automatic sorting, residue dumping and cleaning conveyor has the advantages of having the sorting function, the residue dumping function, the cleaning function and other functions for the tableware; no specially-assigned person is needed for sorting and residue dumping, and after having dinner, a person only needs to place the whole set of tableware and food residues on a conveying and recycling machine at a recycling position and leaves within one second after the whole set of tableware and the food residues are placed. The problems that in the recycling process, people have to queue up for tableware sorting, and contamination is generated in the residue dumping process are solved, recycling time is reduced by more than five times, personnel cost is lowered, and the problem that workers are in shortage and are difficult to hire is solved.

Owner:昆山市新工机械有限公司

Process for producing cellulose ether by directly separating and recovering diluent

The invention discloses a process for producing cellulose ether by directly separating and recovering diluent, which comprises the following steps: adding sodium hydroxide and refined cottons into a mixed diluent system to carry out alkalization reaction; then adding etherifying agent into the obtained mixture to carry out etherification reaction, after the etherification reaction is completed, obtaining a mixed slurry of cellulose ether and organic diluent; and then recycling the organic diluent, and washing and refining the separated cellulose ether so as to obtain a finished product. The process is characterized in that the mixed slurry obtained in the step of etherification reaction is pumped to a centrifugal machine to carry out solid-liquid separation directly; then the obtained liquid mainly comprising the diluent enters into a settling tank to carry out gravity settling, and the obtained liquid subjected to gravity settling is directly used as diluent for recycling; and the obtained solid enters into a recover kettle and then neutralized with acid, and a small amount of diluent contained in the solid is recycled by way of steam heating and distillation. The invention not only greatly reduces the energy consumption in the process of diluent evaporation and recycling, but also recycles the alkali which is not consumed in the reaction, thereby reducing the consumption of acid used in alkali neutralization, saving energy and reducing consumption, and improving the utilization rate of raw materials.

Owner:山东赫达集团股份有限公司

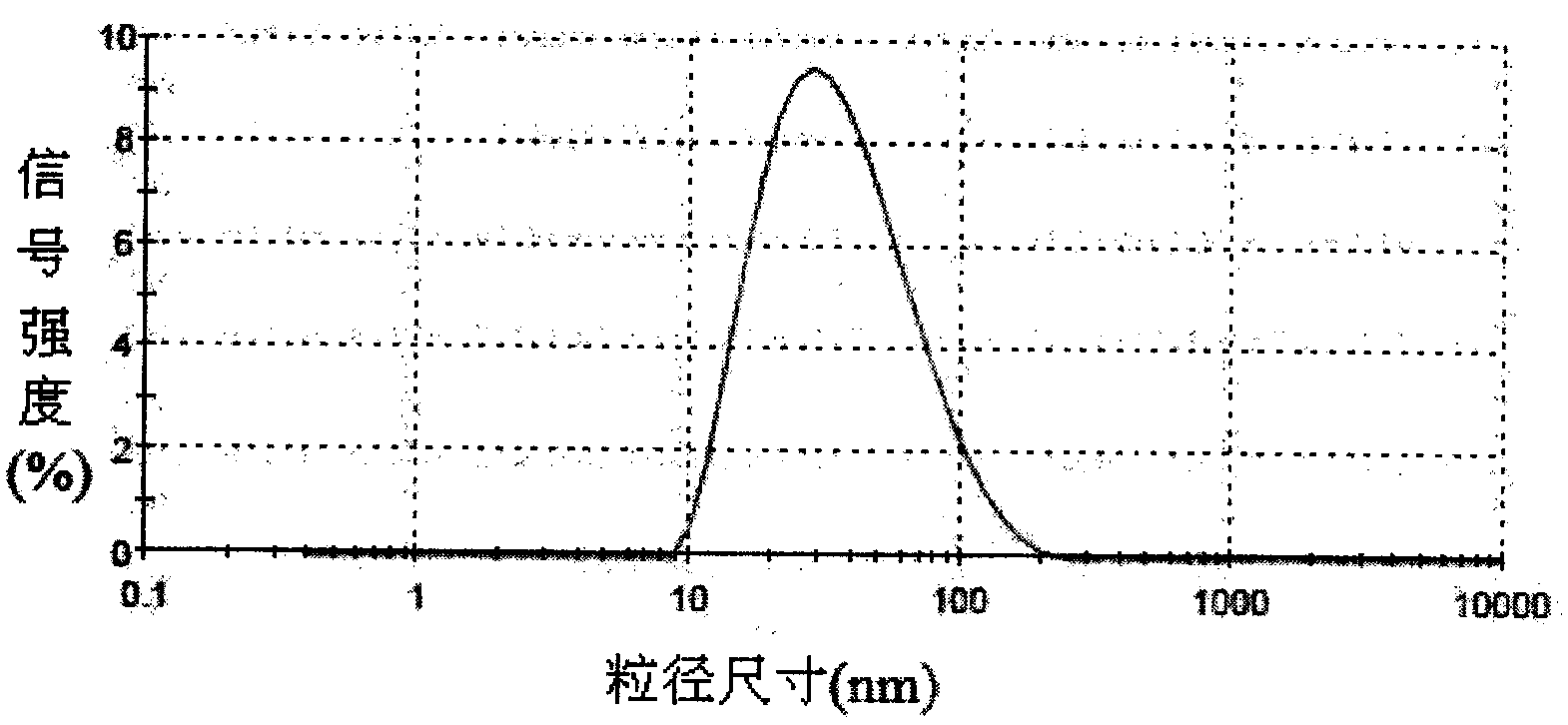

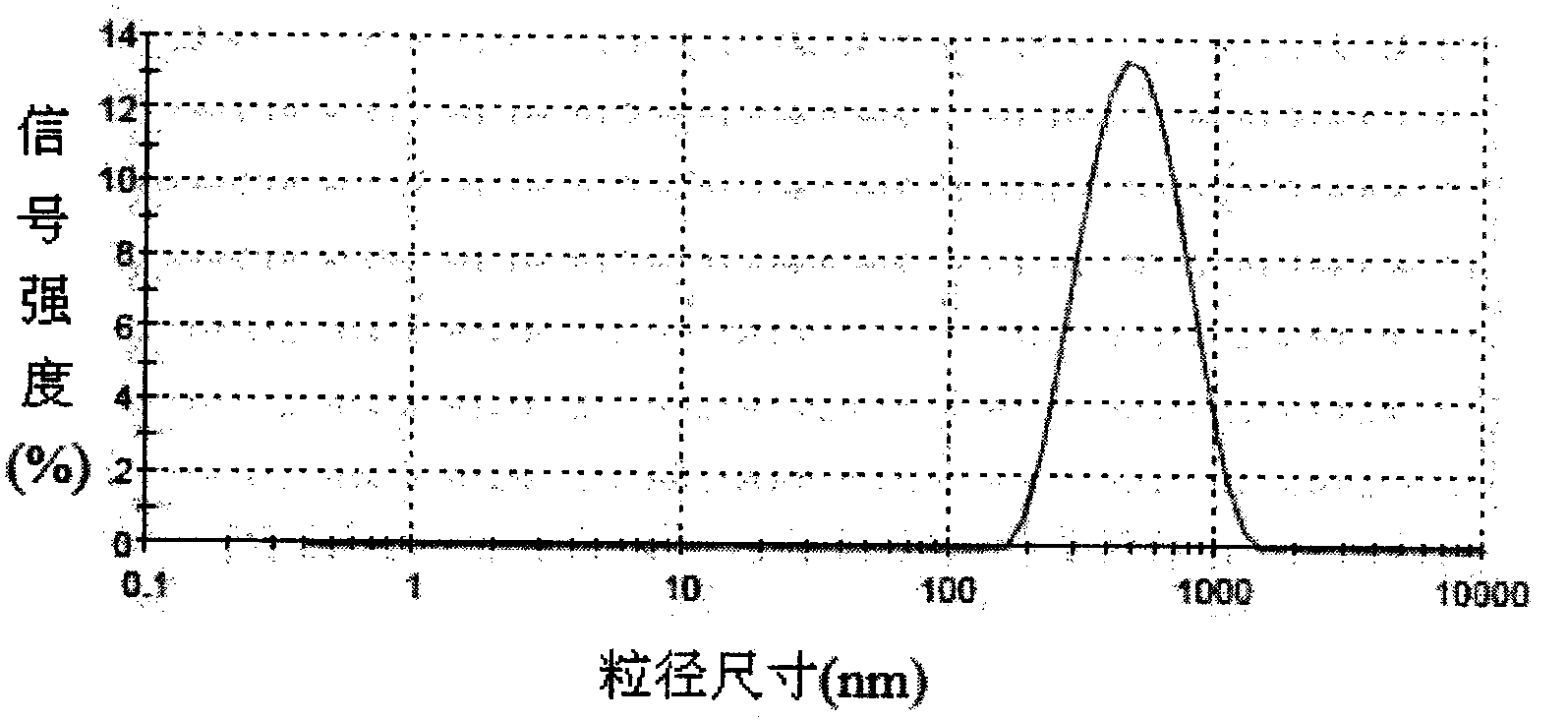

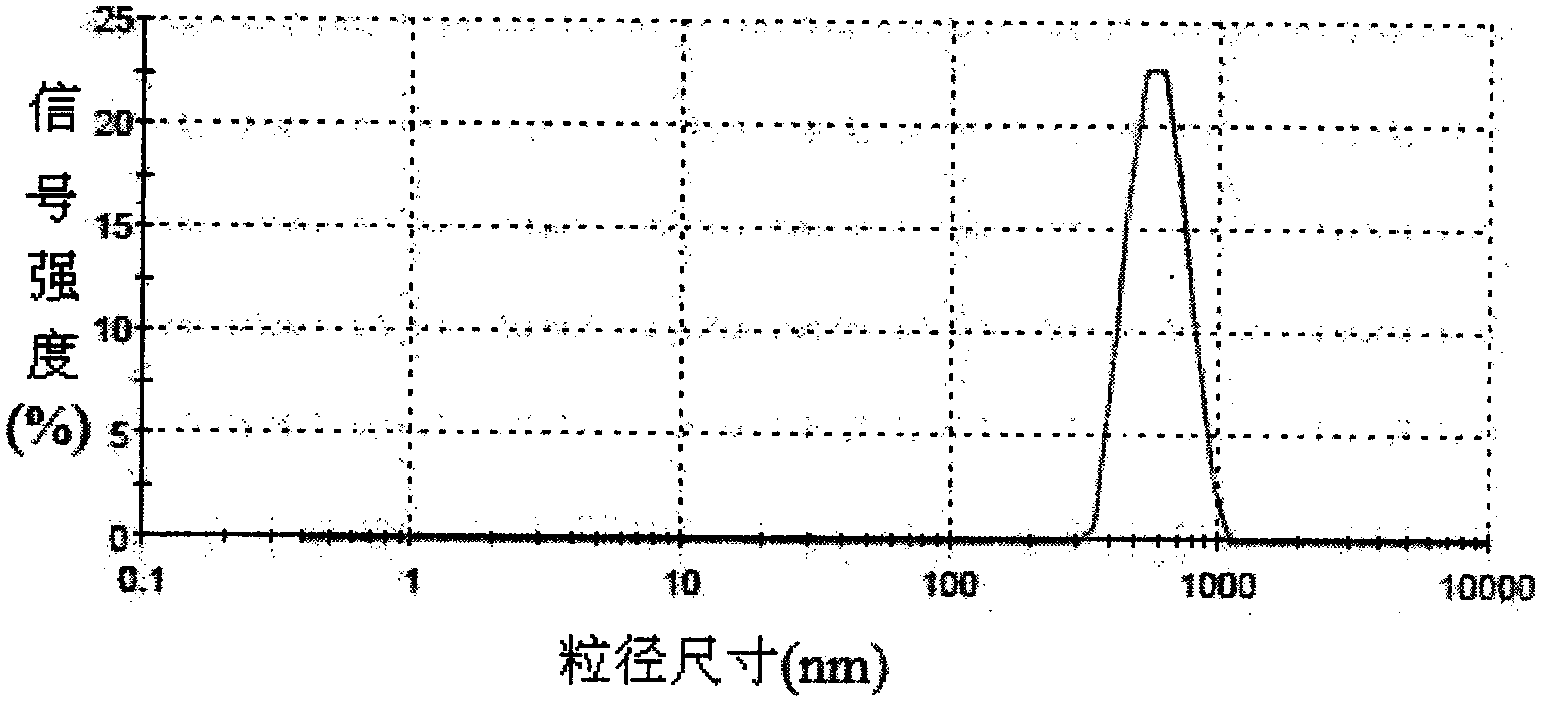

Preparation method of magnetic nanometer carrier for immobilized enzyme

InactiveCN104342431AImprove stabilityStrong cycle timesOn/in organic carrierOn/in inorganic carrierAlkaline earth metalBiocompatibility Testing

The invention discloses a preparation method of a magnetic nanometer carrier for immobilized enzyme. The carrier takes nano Fe3O4 as a core and alginic acid alkaline-earth metal salt as a shell; the carrier has the characteristics of being small in particle size, uniform in particle, good in monodispersity, large in specific surface area, good in chemical stability, strong in load capacity, good in biocompatibility, strong in magnetic response and the like. The preparation method of the magnetic nanometer carrier comprises the following steps: (1) preparing nano Fe3O4 in a reverse microemulsion system; (2) adding a sodium alginate solution to a reaction system, mixing evenly, and then adding an alkaline-earth metal salt solution; (3) after reaction is ended, obtaining the magnetic nanometer carrier by separation and purification. The preparation method of the magnetic nanometer carrier related to the invention is mild in reaction condition, simple in preparation, and controllable in carrier particle size and pore structure in the preparation process.

Owner:ZUNYI MEDICAL UNIVERSITY

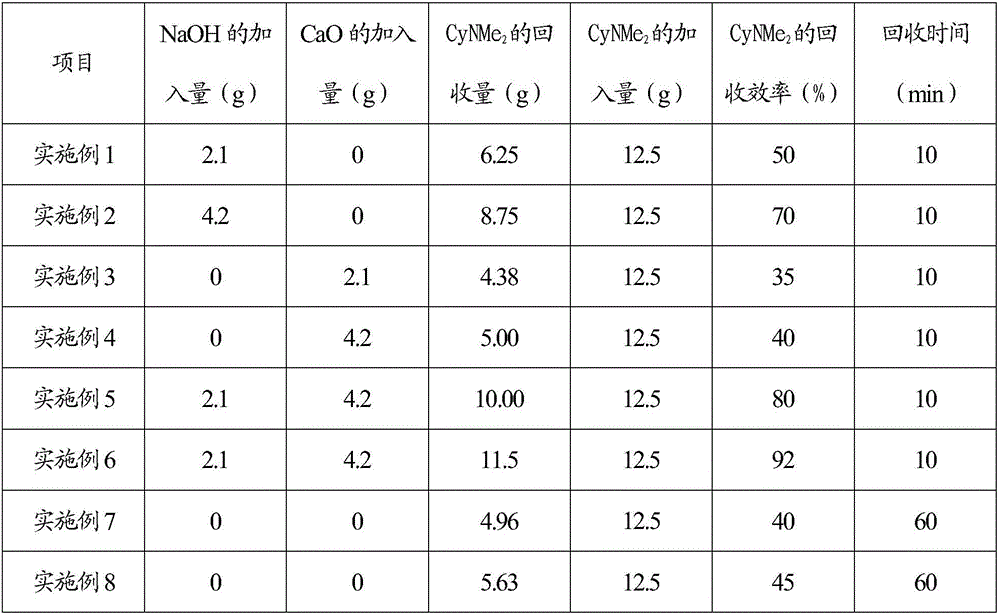

Recovering method for CO2 switch type solvent for treating oil-based drilling cuttings

ActiveCN105925300AShort time spentImprove solvent recovery efficiencyLiquid hydrocarbon mixture productionSolventSolid phases

The invention discloses a recovering method for CO2 switch type solvent for treating oil-based drilling cuttings. The recovering method includes the steps that solid sodium hydroxide is added into the water phase containing CO2 switch type solvent and stirred to be dissolved, and an upper layer oil phase and a lower water phase are separated; solid calcium oxide is added into the water phase obtained after separation and stirred to be dissolved, an upper layer oil phase, a middle layer water phase and a lower layer solid phase are separated out; the oil phase obtained through separation is the recovered CO2 switch type solvent. The time needed for recovering the solvent is greatly shortened, solvent recovering efficiency is effectively improved, quality of wastewater obtained after separation is improved well, and the recovering method can be used for pretreating organic amine wastewater.

Owner:SOUTHWEST PETROLEUM UNIV +1

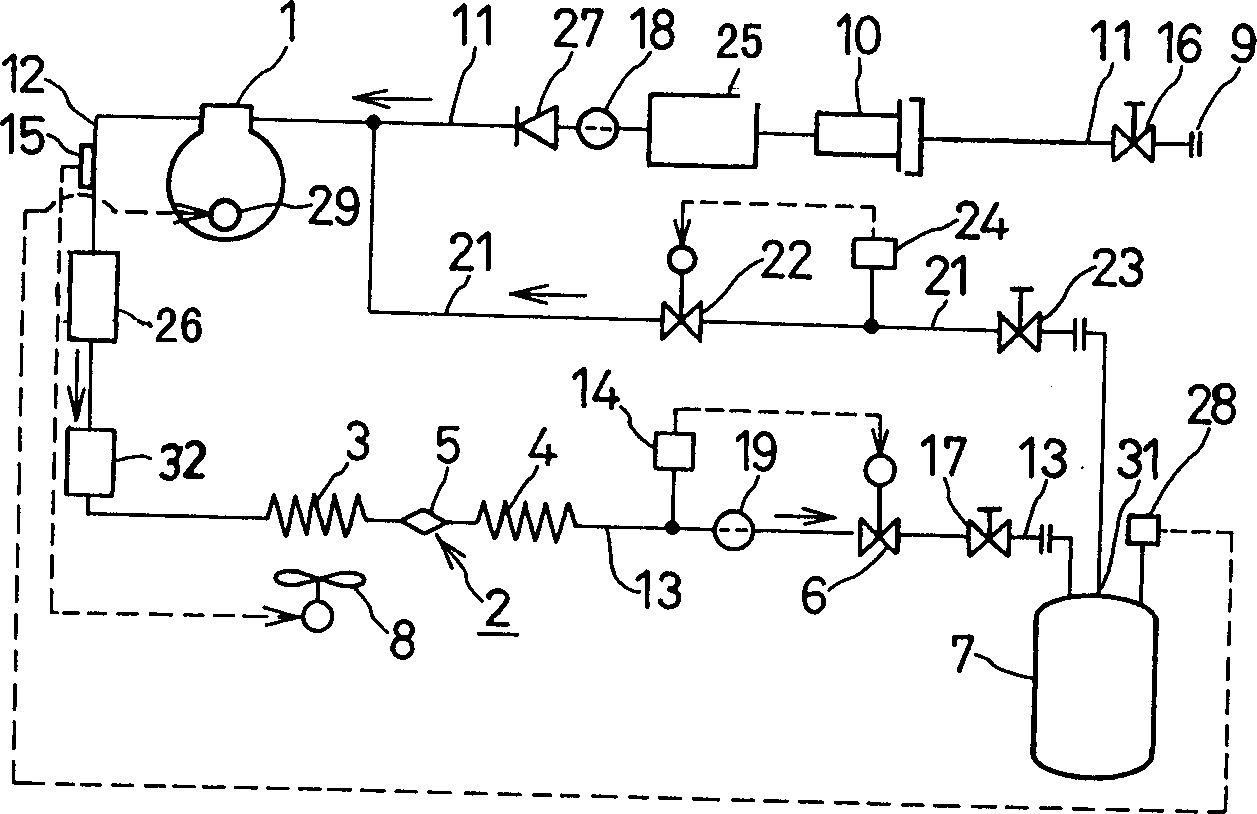

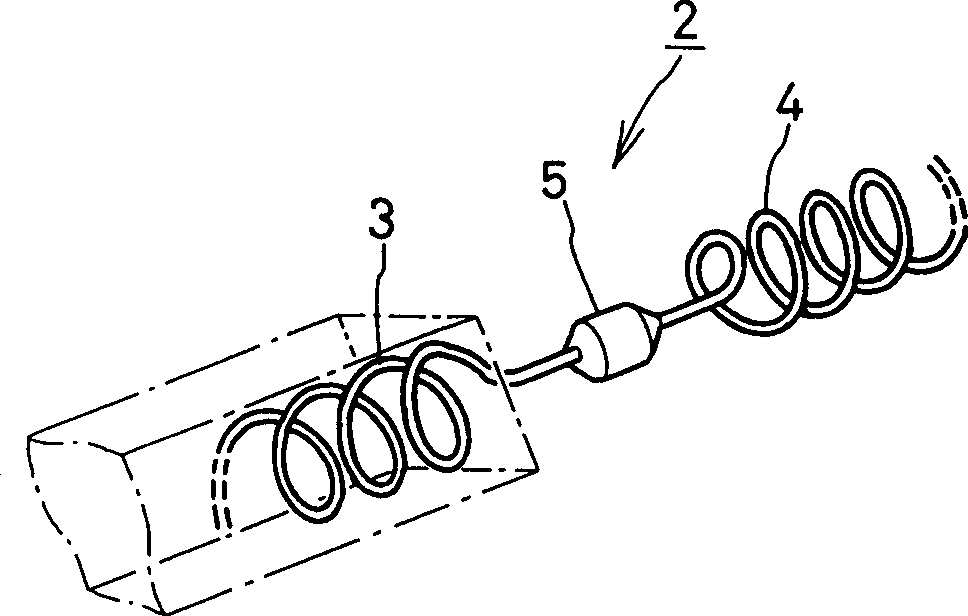

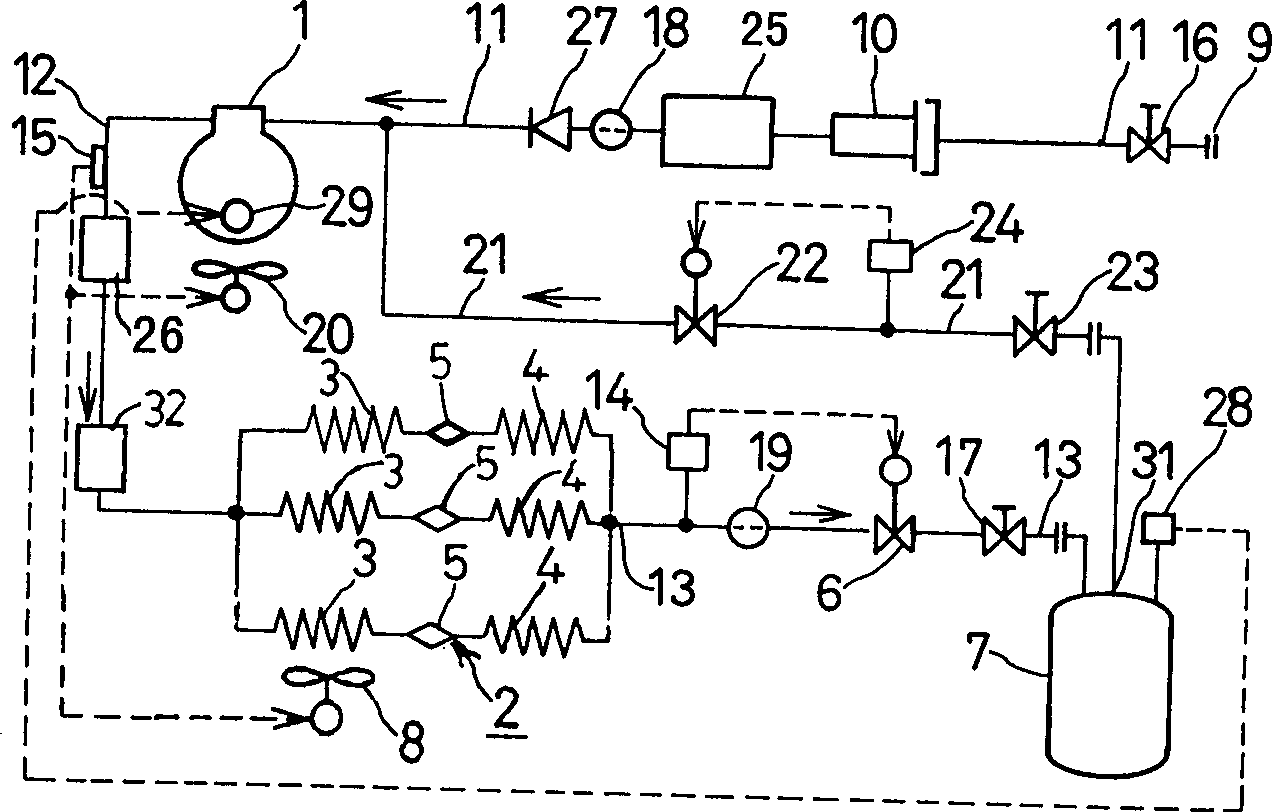

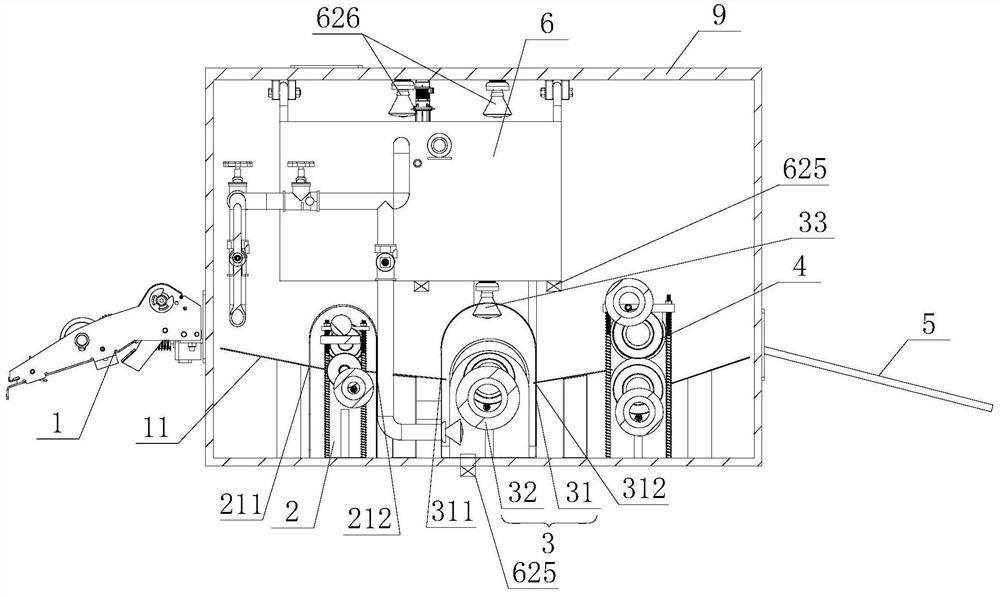

Refrigerant recovery device

InactiveCN1346957AEasy to operateLow costMechanical apparatusStationary conduit assembliesRefrigerant reclamationSolenoid valve

A refrigerant recovery device comprises a compressor 1 which draws in chlorofluorocarbons gas. Chlorofluorocarbons gas that has increased pressure and temperature by being discharged from the compressor 1 is conducted through a heat exchange device 2 to become liquid refrigerant. The liquid refrigerant is conducted by a liquid pipe 13 to a refrigerant recovery tank 7. Gas of the refrigerant inside the refrigerant recovery tank 7 is conducted to the compressor 1 by a gas pipe 21. The heat exchange device 2 comprises the first helical piping 3 formed by winding a small diameter heat transfer pipe, a large diameter tube 5 with a cross-sectional area larger than the previous heat transfer pipe and the second helical, small-diameter piping 4 with a structure similar to the first helical small-diameter piping 3, these elements being connected in serial as a single unit, or alternatively the heat exchange device comprises two or more single units connected together. The liquid pipe 13 comprises a solenoid valve 6 that is controlled by a pressure sensor 14 to open at a preset upper value and to close at a preset lower value. The gas pipe 12 comprises a solenoid valve 22 that is controlled by a pressure sensor 24 to open at a preset upper value and to close at a preset lower value. The present invention provides a refrigerant recovery device that is cheap, compact and is portable and easy to operate for inexpensively recovering chlorofluorocarbons.

Owner:岩崎 照皇

Method for recovering triethylamine, removing phosphorus pollutants and recovering phosphorus resources in glyphosate mother liquor

InactiveCN105130822AReduce contentHigh total removal rateAmino compound purification/separationMultistage water/sewage treatmentDesorptionWater vapor

A method for recovering triethylamine, removing phosphorus pollutants and recovering phosphorus resources in glyphosate mother liquor comprises operation steps as follows: (1) calcium hydroxide powder or a calcium hydroxide emulsion is added to the glyphosate mother liquor, the mixture is evenly mixed, the calcium hydroxide powder or the calcium hydroxide emulsion is required to be added to enable the pH value of the glyphosate mother liquor to range from 10.5 to 12.3, then the glyphosate mother liquor is heated to the temperature higher than 85 DEG C for a reaction for 0.5-3 h while stirring is performed, triethylamine vapor produced in the reaction is collected and condensed, and a triethylamine solution is obtained; (2) a solid-liquid mixture formed through the reaction is subjected to water vapor gas-stripping desorption, a gas discharged through water vapor gas-stripping desorption is condensed, and a triethylamine solution is obtained; (3) the triethylamine is obtained through dehydration treatment of the obtained triethylamine solutions; (4) a coagulant is added to the solid-liquid mixture obtained after water vapor gas-stripping desorption while stirring is performed, the mixture is evenly mixed, then solid-liquid separation is performed after a reaction while stirring is performed, obtained solid substances are used as the phosphorus resources to be recycled, and an obtained liquid is collected for further treatment.

Owner:SICHUAN LECHUANG TECH CO LTD

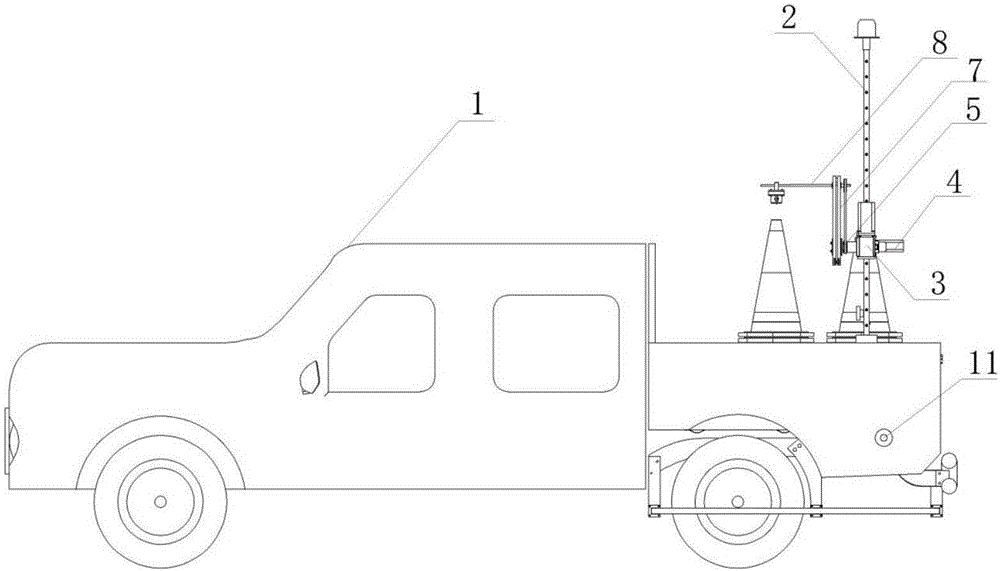

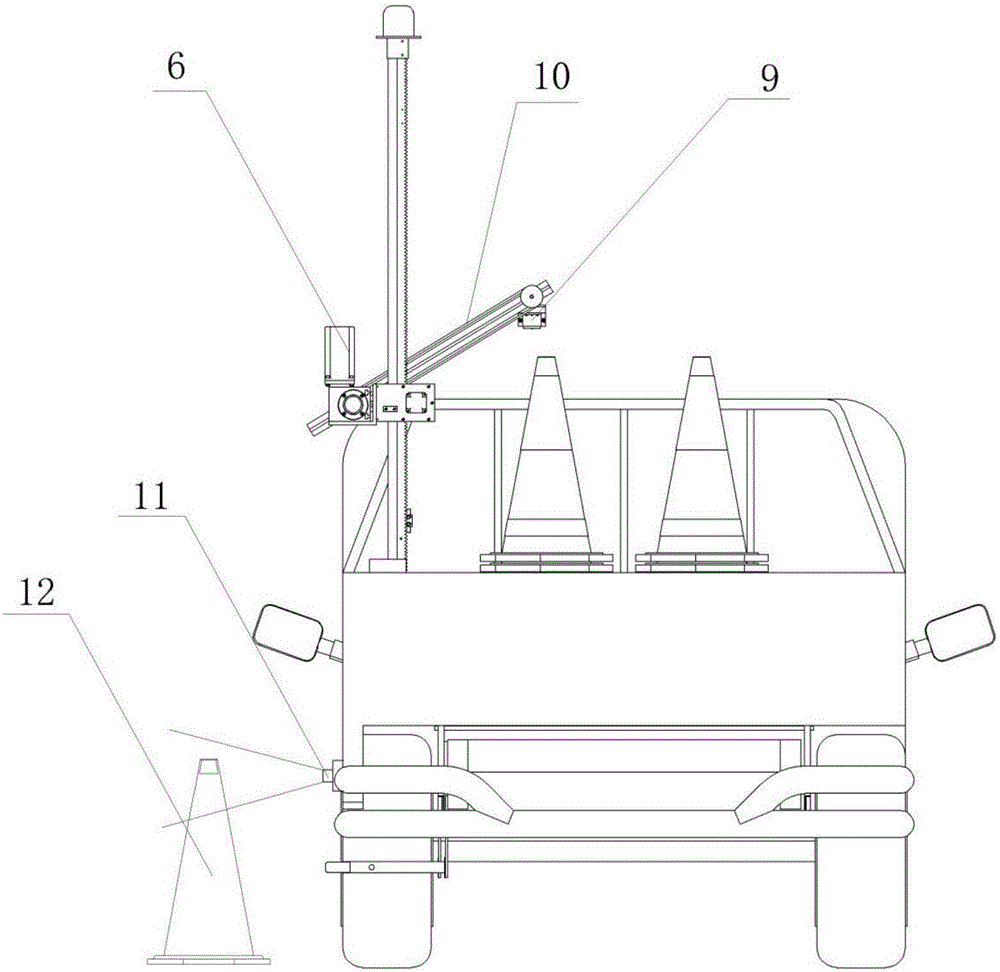

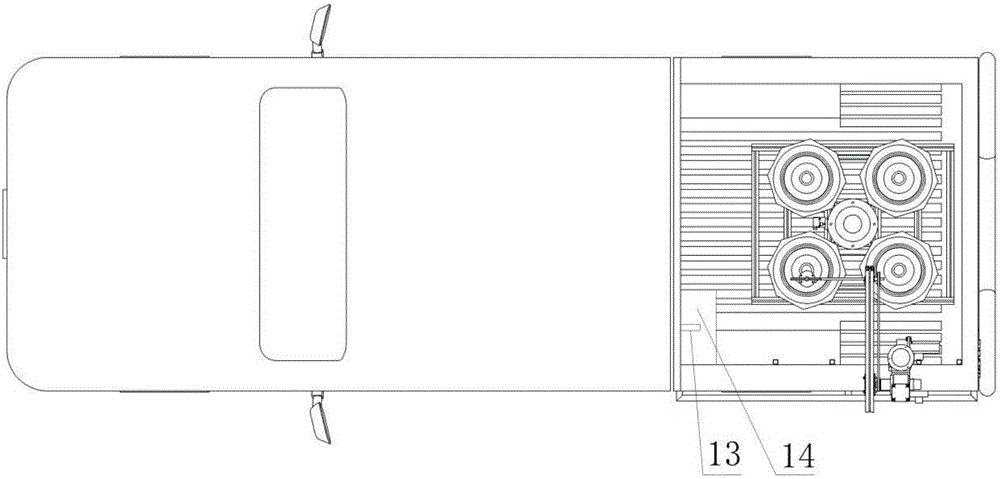

Road cone automatic recovery device and recovery method thereof

The invention discloses a road cone automatic recovery device. The road cone automatic recovery device comprises a vehicle-borne platform, compartment side ripping fences, a lifting mechanism and a rocker arm mechanism and further comprises a laser radar assistant positioning device and a recovery control device, wherein the laser radar assistant positioning device comprises laser radar sensors installed on the compartment side ripping fences, and the laser radar sensors are electrically connected with the recovery control device; and the recovery control device is electrically connected with a lifting motor of the lifting mechanism and a rocker arm motor of the rocker arm mechanism. According to the road cone automatic recovery device disclosed by the invention, on the one hand, the situation that mechanical structures in the road cone pushing over aspect are additionally arranged is avoided, and the structure of the recovery device is simplified; and on the other hand, road cones are positioned through the laser radar sensors, so that manual operation is simplified, the recovery time is shortened, and the recovery efficiency is improved.

Owner:WUHAN UNIV OF TECH

Overflow shutoff valve for liquefied gas container

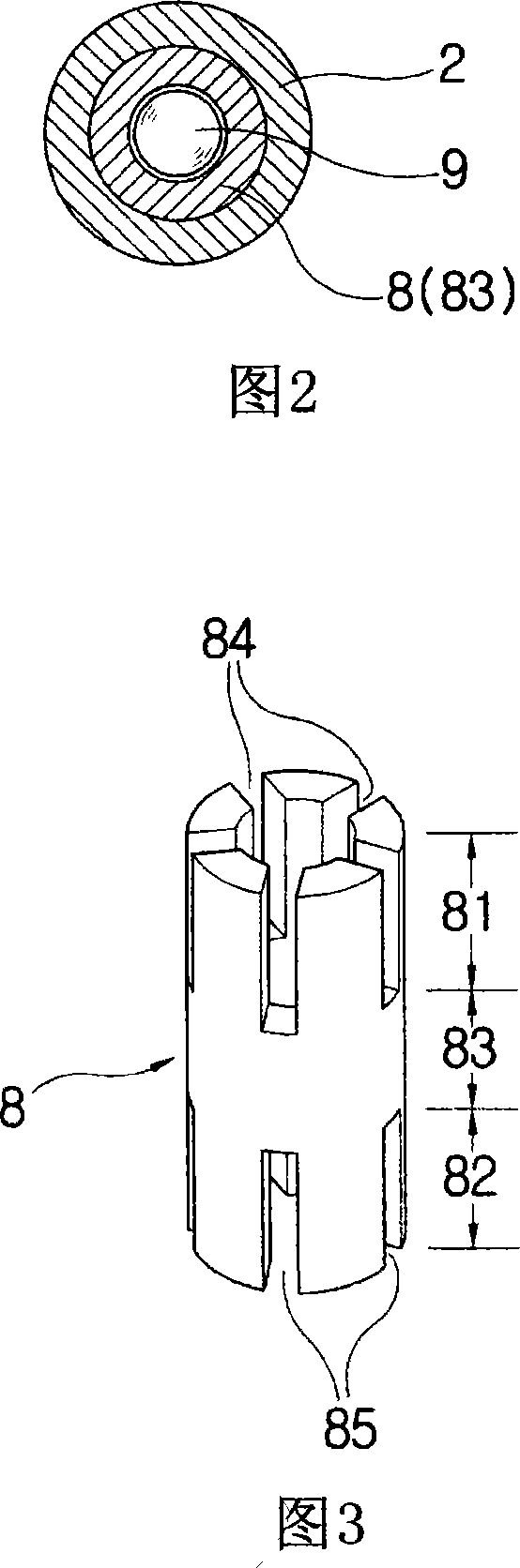

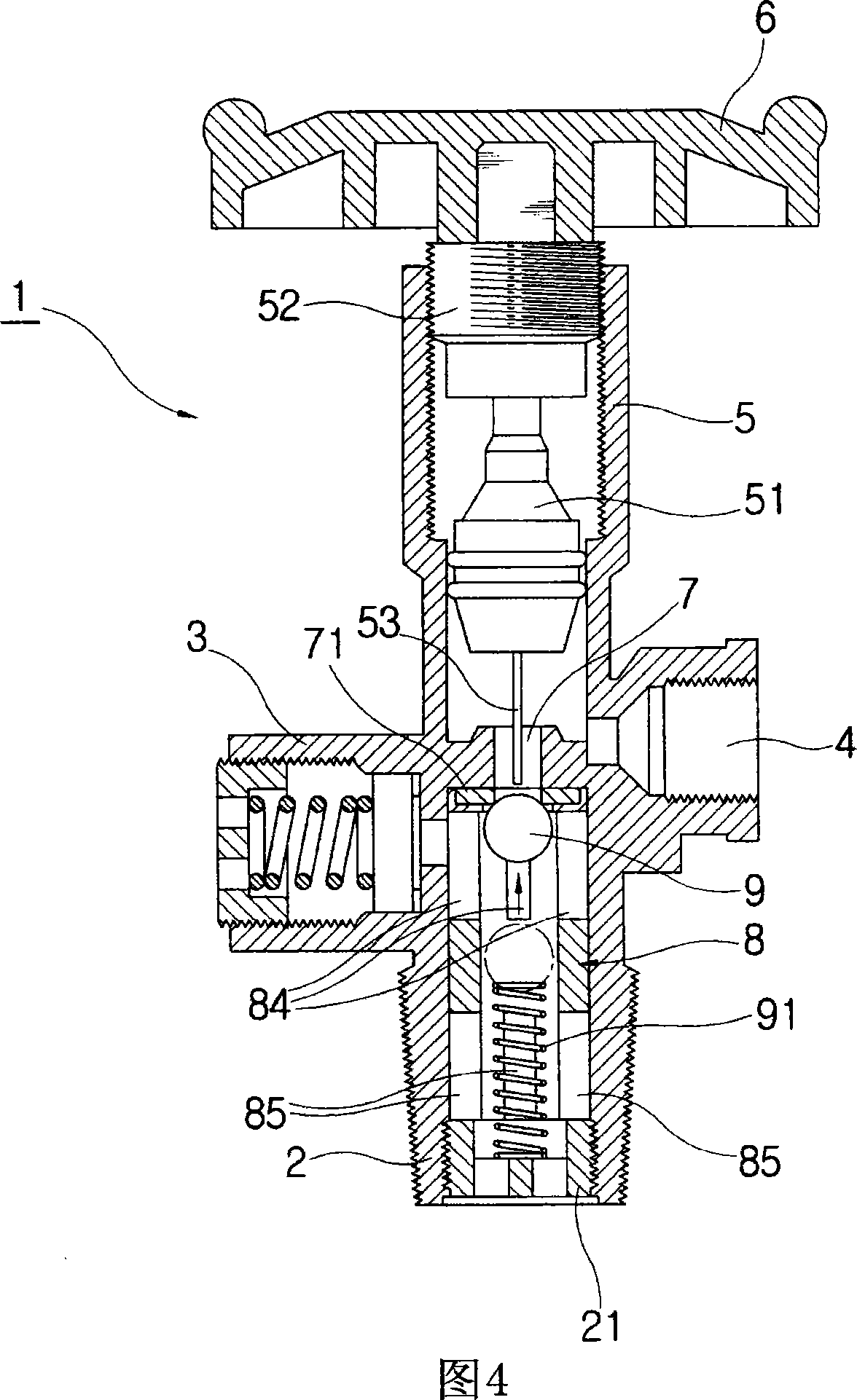

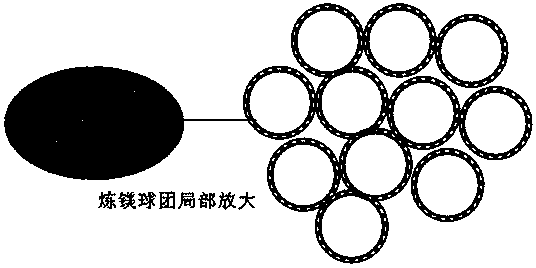

ActiveCN101228390APrevent overflowSave material costVessel mounting detailsVessel geometry/arrangement/sizeInternal pressureEngineering

Disclosed herein is an over-flow shutoff valve for a liquefied petroleum gas container The overflow shutoff valve includes: a gas inlet mounted at the gas container; a safety valve protrudingly formed at one side of the upper portion of the gas inlet for discharging the internal pressure of the gas container when the internal pressure is rapidly increased; a gas outlet protrudingly formed at the other side of the upper portion of the gas inlet for supplying gas to a gas appliance; a valve handle for vertically controlling a valve stem mounted on a controlling part protruding from the upper portion of the gas inlet; a gas inflow and outflow hole located between the gas inlet and the controlling part for allowing inflow and outflow of the gas; a cylinder fit into the inner circumference of the gas inlet; and a ball positioned inside the cylinder, the cylinder and the ball being adapted to normally discharge the gas contained in the gas container and regulate a gas flow to prevent an excessive outflow of the gas, wherein the cylinder has an upper part, a lower part and an intermediate part between the upper and lower parts, each of which has the same thickness, and is made of a hollow pipe, the upper part having a plurality of upper incised slots of a uniform length vertically formed on the circumference thereof in an axial direction in such a manner as to be spaced apart from one another at regular intervals and be opened upwardly, and the lower part having a plurality of lower incised slots of a uniform length vertically formed on the circumference thereof in the axial direction in such a manner as to be spaced apart from one another at regular intervals and be opened downwardly.

Owner:申一换

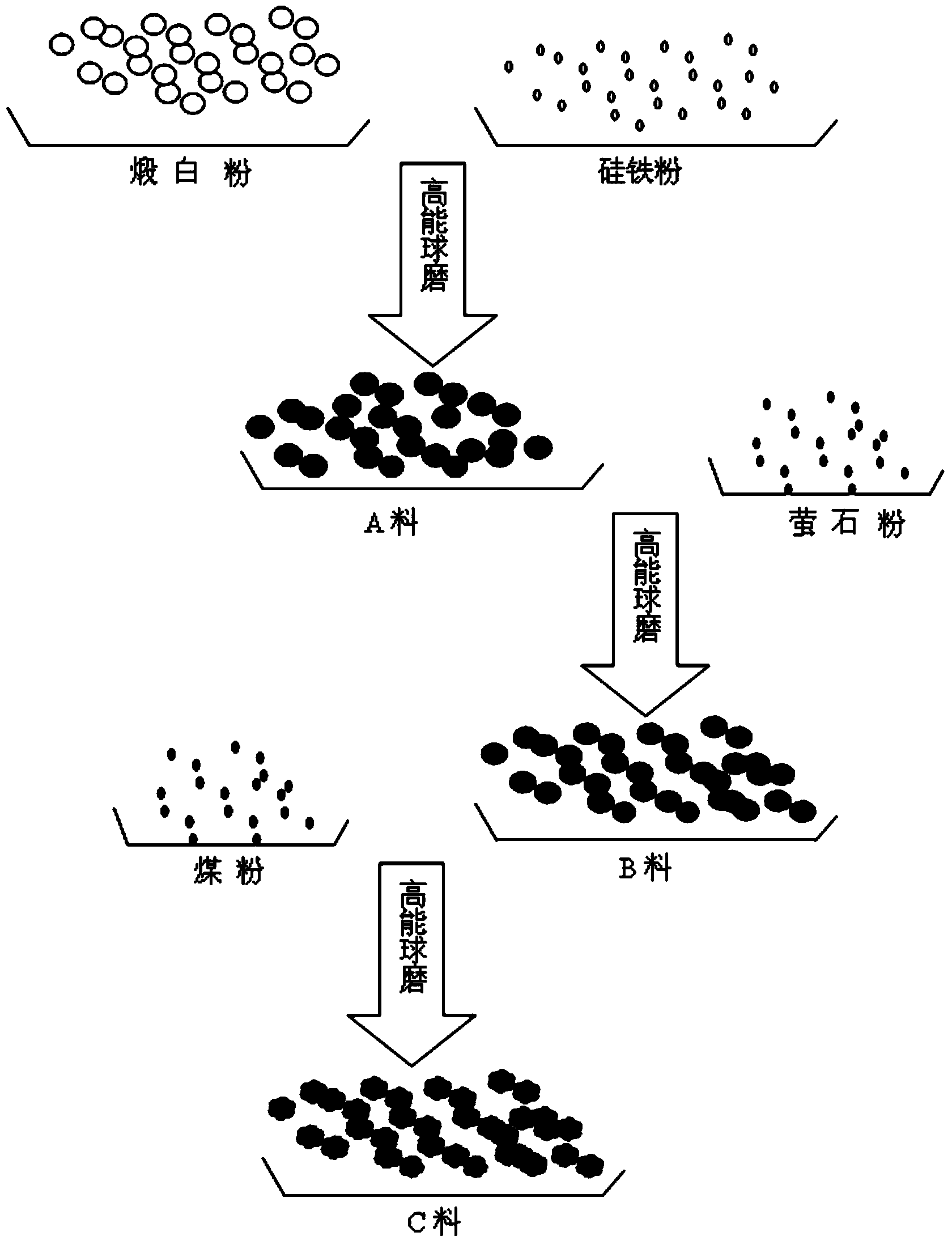

Magnesium smelting raw material pellet capable of improving transverse tank magnesium smelting efficiency and preparation method thereof

InactiveCN103981377AHigh recovery rateReduce the temperature difference between inside and outsideIron powderFerrosilicon

The invention provides a magnesium smelting raw material pellet capable of improving transverse tank magnesium smelting efficiency. Raw materials of the magnesium smelting raw material pellet comprise the following components in percentage by weight: 80% of calcined dolomite powder, 5-10% of ferrosilicon powder, 2-4.8% of fluorite powder and 5.2-13% of pulverized coal, wherein the total weight of the raw materials is 100%. Calcined dolomite, ferrosilicon ores, fluorite and coal ores are used as raw materials, and are respectively ground into fine powder by virtue of a ball mill so as to ensure that the particle size of the calcined dolomite powder is less than 100 meshes, the particle size of the ferrosilicon powder is less than 200 meshes, the particle size of the fluorite powder is less than 200 meshes, and the particle size of the pulverized coal is less than 200 meshes; the obtained calcined dolomite powder, ferrosilicon powder, fluorite powder and pulverized coal are sequentially mixed uniformly, then are added into a two-roller ball press machine without adding any binding agent, and are directly pressed to obtain the magnesium smelting raw material pellet. The magnesium smelting raw material pellet provided by the invention can be used for effectively improving the magnesium recovery ratio, saving the recovery time, improving the production efficiency of the magnesium industry, reducing the cost, and providing a larger space for the development of the industry.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

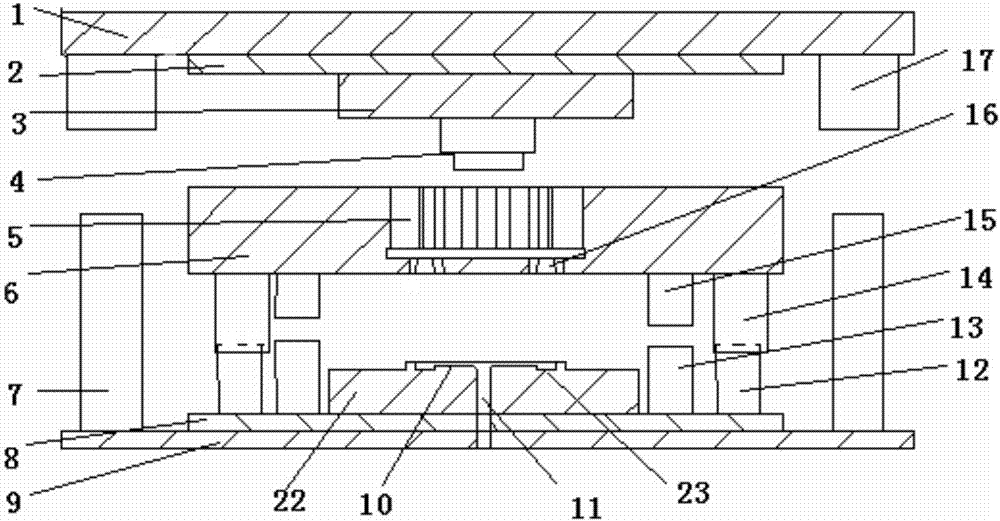

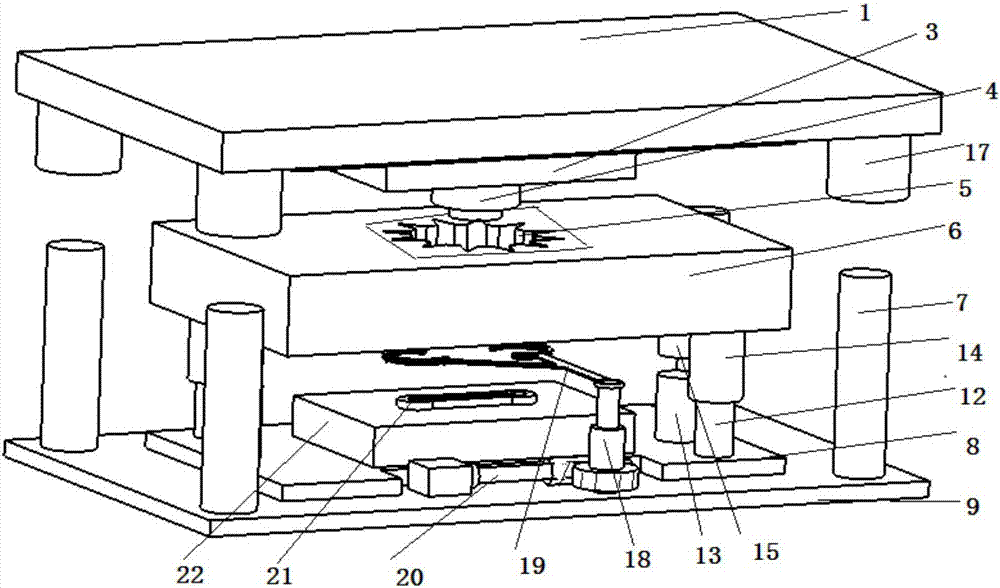

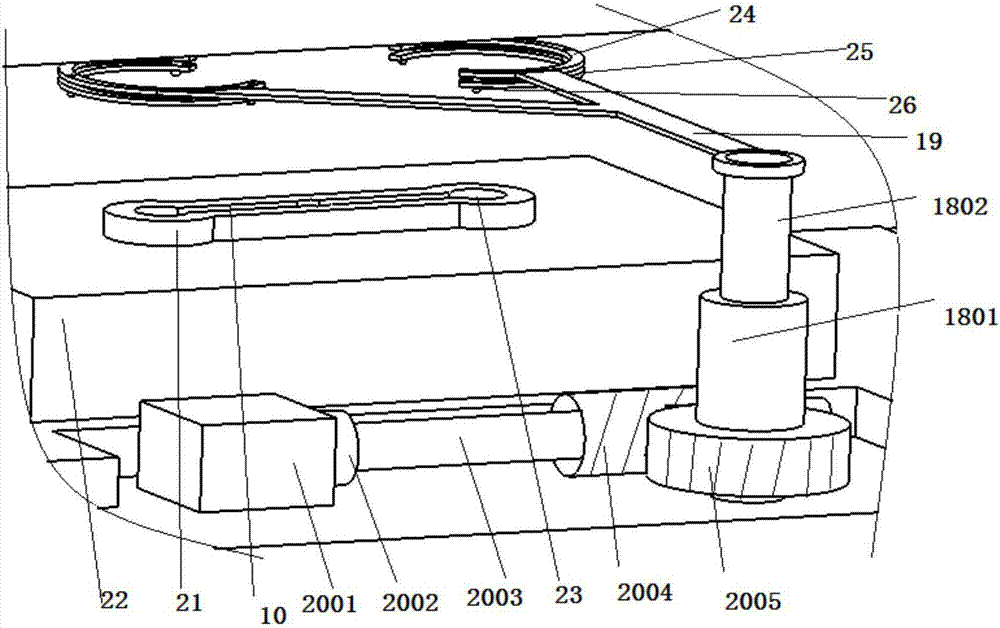

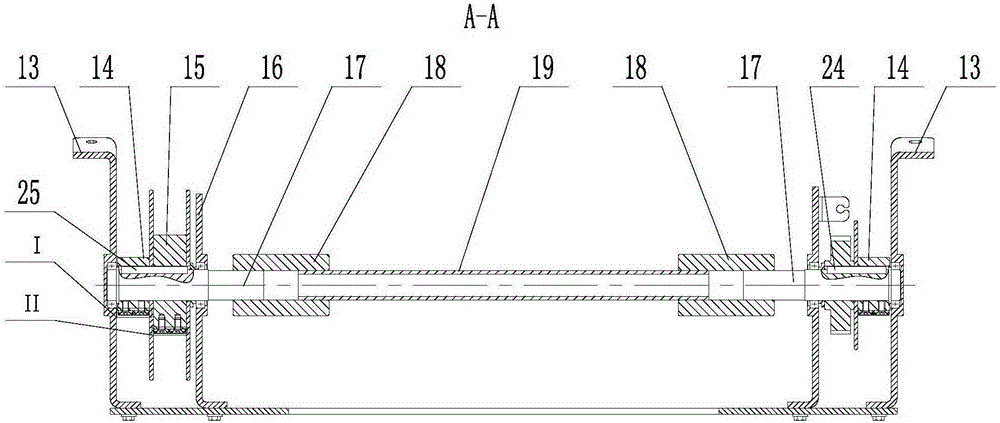

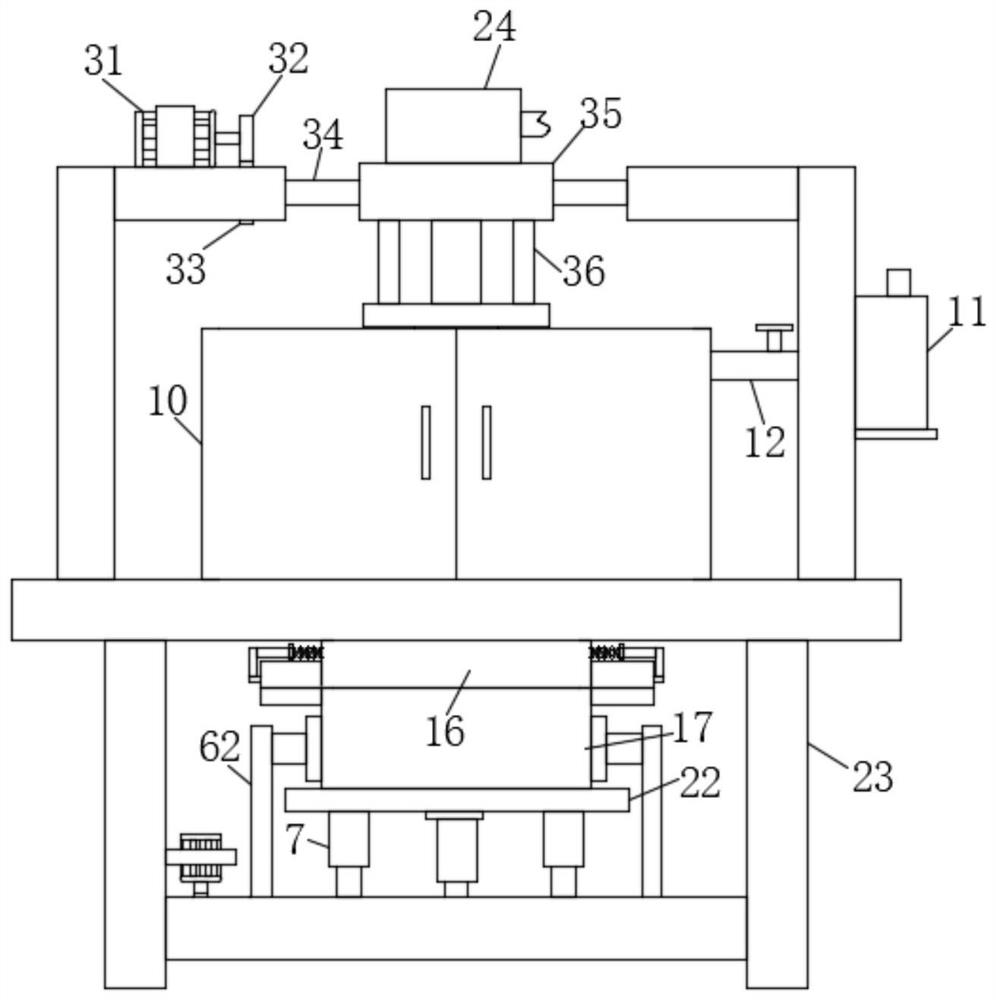

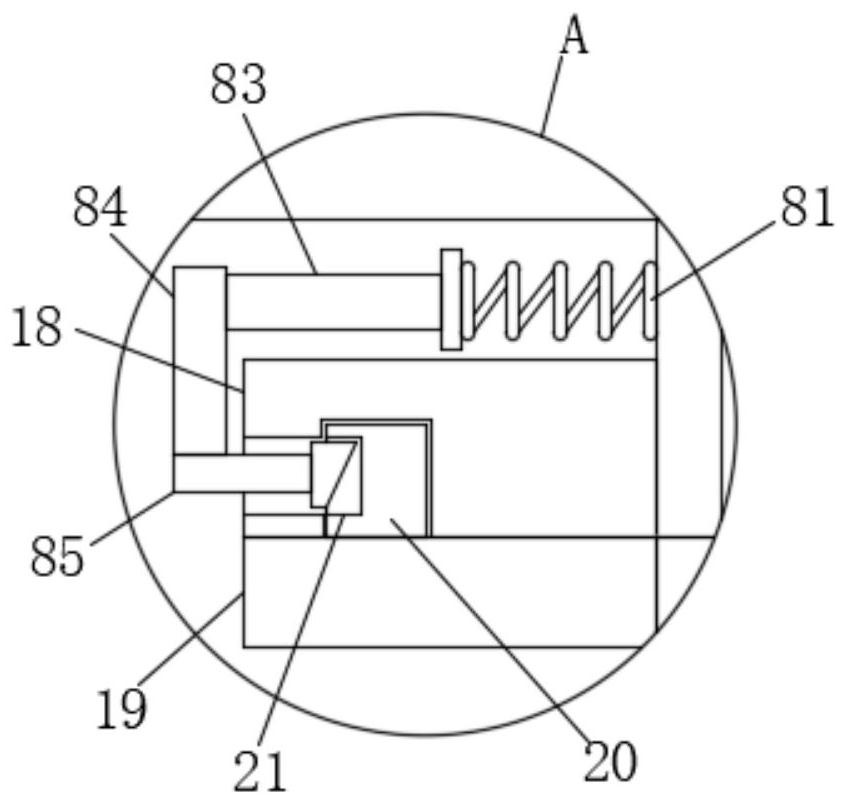

Novel die-casting die for automobile part

The invention provides a novel die-casting die for an automobile part. The novel die-casting die comprises an upper die seat, an upper cushion plate, a male die fixing plate, a female die fixing plate, a fixing plate, a lower cushion plate and a lower die seat which are sequentially arranged from top to bottom. Guide columns and guide sleeves are evenly distributed between the upper die seat and the lower die seat. Symmetric conic through holes are formed in the position, corresponding to a female die, of the bottom of the female die fixing plate. Grooves corresponding to the conic through holes are formed in the upper surface of the fixing plate. The two grooves are connected through an arc trench to form a sub-runner. The female die fixing plate and the fixing plate are in sliding fit connection through small guide columns and small guide sleeves. According to the novel die-casting die for the automobile part, for a casting with a symmetric structure, it is guaranteed that the separating face during automatic separation of the casting and waste is smooth during demolding, a workpiece cannot be damaged, material waste is reduced, and renovation on the automobile part after die casting is low; the workload of workers is saved; and the work efficiency is improved.

Owner:大川精工(朝阳)有限公司

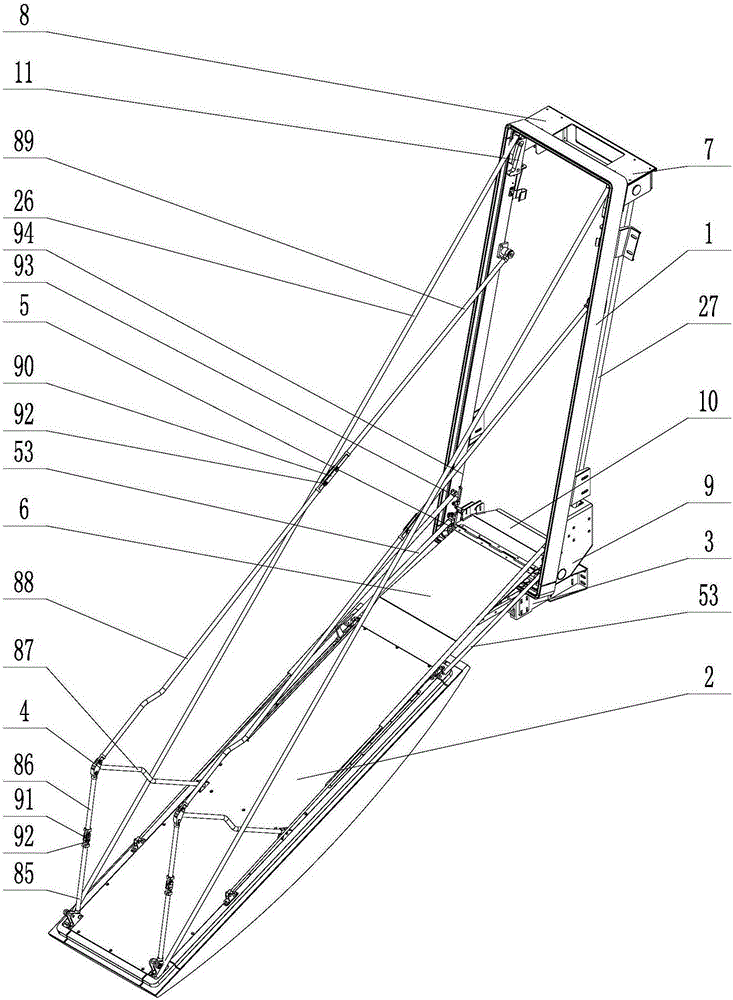

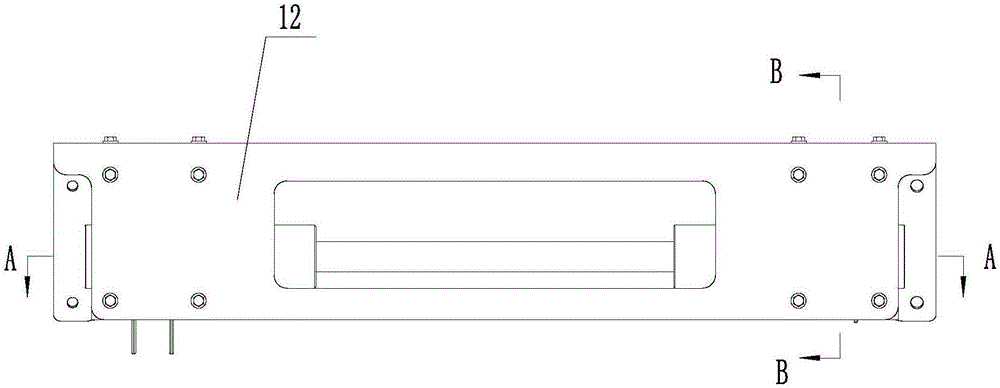

All-purpose escape system for subway locomotives

ActiveCN105172815ASimple structureImprove reliabilityDoor arrangementLocking mechanismElectrical and Electronics engineering

The invention relates to an all-purpose escape system for subway locomotives. The all-purpose escape system comprises a sealing frame, a door leaf, an ejecting mechanism and a lock mechanism, wherein the sealing frame and the ejecting mechanism are fixed on a locomotive body; the opening direction of the door leaf faces forwards; one end of the door leaf is hinged to the front end of the ejecting mechanism; the door leaf adopts a structure that after the door leaf is ejected forwards in a translating manner, the door leaf rotates downwards; the lock mechanism is mounted on the inner side of the sealing frame in an integrated manner; when the door leaf is ejected in a translating manner by the ejecting mechanism and rotates, the door leaf automatically opens; when the door leaf withdraws to the middle of the sealing frame, the lock mechanism automatically performs locking. The escape system is light in weight, occupies a small space, is opened or withdrawn in one step, high in recovery efficiency, simple in structure, high in reliability, and large in pass width; besides, the escape system is guaranteed to be suitable for various locomotive types.

Owner:KTK GRP

Spraying device with coating recovery structure

The invention discloses a spraying device with a coating recovery structure. The spraying device comprises a fixing table, fixing frames are fixedly connected to the two sides of the upper end of the fixing table, the upper ends of the two fixing frames are fixedly connected through an adjusting mechanism, and a conveying box is installed at the upper end of the adjusting mechanism. The device has the beneficial effects that two moving blocks are driven to move through a third threaded rod and a second threaded rod, the two moving blocks drive two clamping plates to move, the two clamping plates drive two clamping blocks to move, the two clamping blocks drive two anti-skid plates to move towards the side close to a material collecting frame, the material collecting frame is pushed, the material collecting frame is located in the middle of a supporting plate and aligned with a connecting frame, a fourth bevel gear drives a fourth threaded rod to rotate, the fourth threaded rod drives a lifting pipe to move, the lifting pipe drives an installation plate to move, the installation plate drives a supporting plate to ascend, and therefore the material collecting frame is driven to be connected with the connecting frame, the automation degree is high, and the time for workers to install the material collecting frame is shortened.

Owner:无锡润安涂装科技有限公司

Recycling method of triethylamine and methylbenzene in combination of organophosphorus ester

ActiveCN102816070AReduce pollutionVolatileAmino compound purification/separationDistillation purification/separationIndustrial waste waterDistillation

A recycling method of triethylamine and methylbenzene in combination of organophosphorus ester relates to technology for recycling triethylamine and methylbenzene from industrial waste water produced in combination of organophosphorus ester and resolves the technical problem of recycling of triethylamine and methylbenzene in industrial waste liquid. The recycling method includes the following steps: placing waste liquid produced combination of organophosphorus ester in a reactor, adding solid calcium oxide in stirring mode, conducting complete reaction, conducting heating and distillation after the pH value achieves 11-12, collecting distillate of 60-120 DEG C, adding a drying agent into collected mixed liquid of triethylamine, methylbenzene and water to conduct heating and backflow for 48 min to remove moisture and then conducting distillation again to obtain triethylamine and methylbenzene. The recycling rate is no smaller than 98%, methylbenzene is smaller than 0.005ppm in the industrial waste liquid after triethylamine and methylbenzene are recycled, and the recycled mixed liquid of triethylamine and methylbenzene can be applied to combination of organophosphorus ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

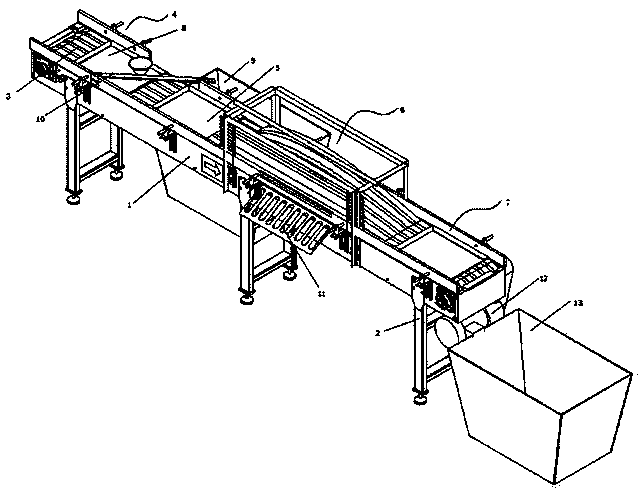

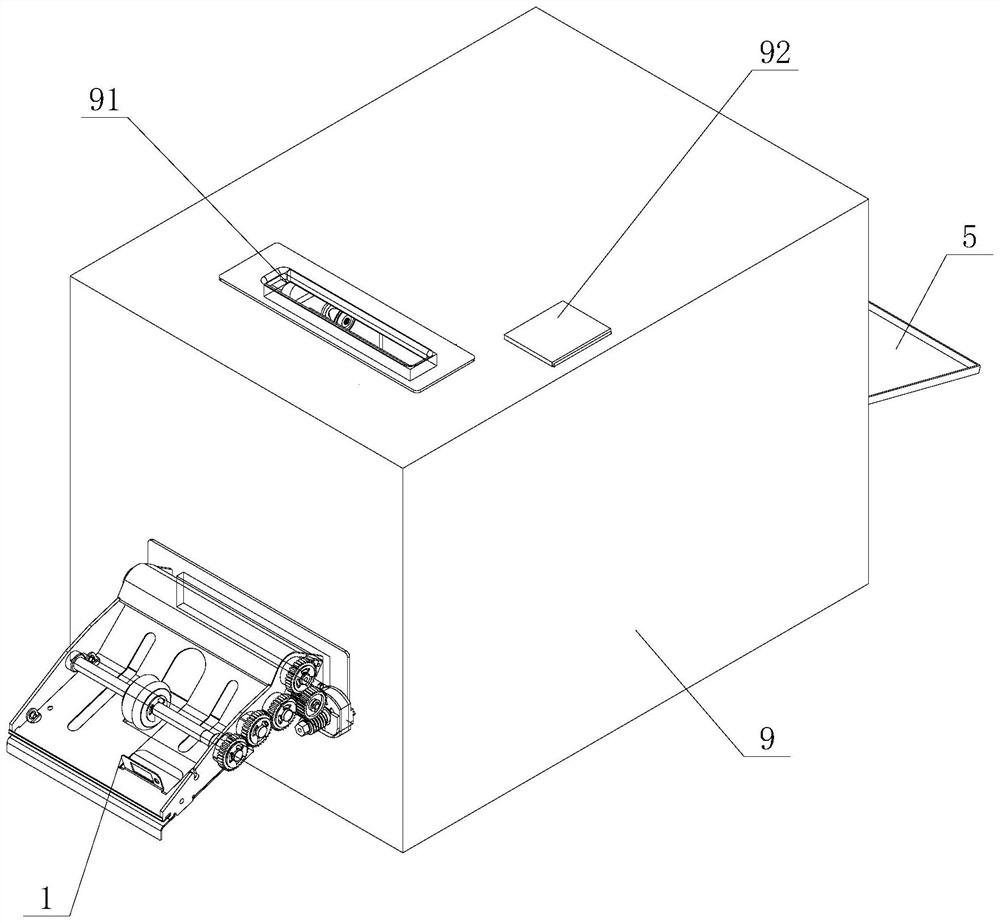

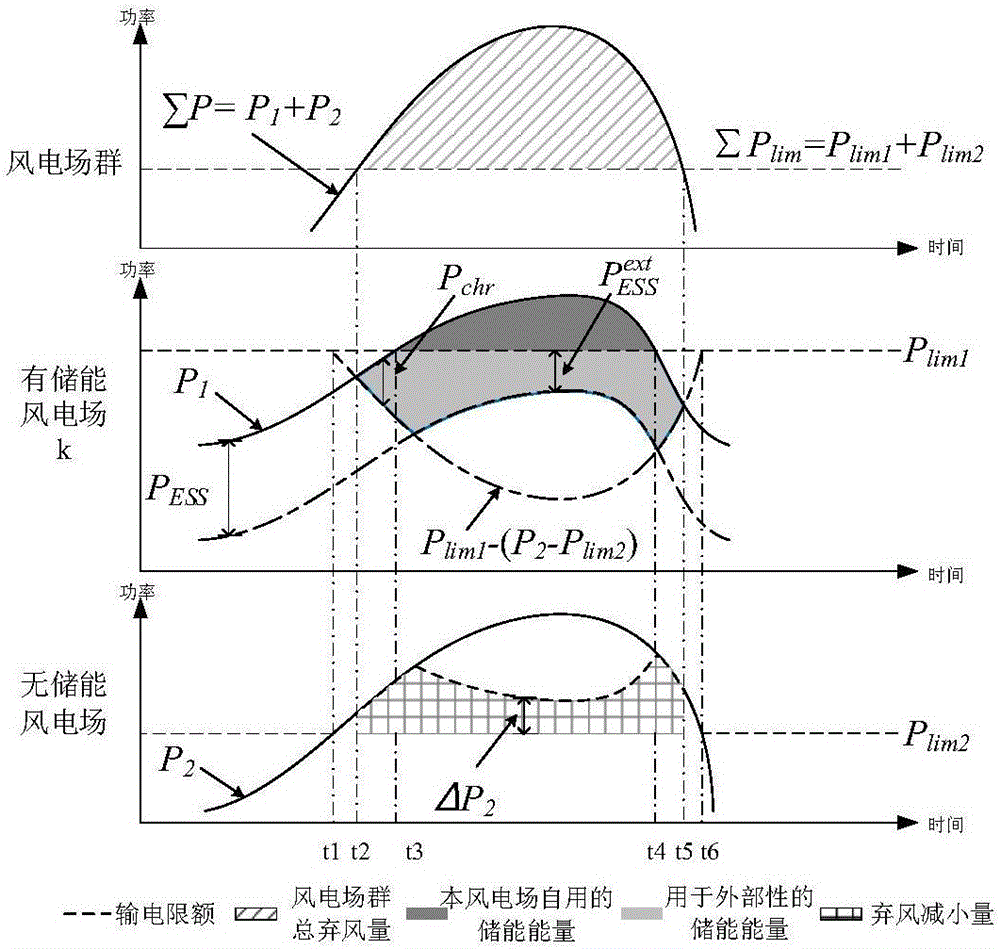

Waste paper regeneration device and paper making method thereof

PendingCN113089352AShorter payback timeSave money costRaw material pretreatmentProcess engineeringPaper sheet

The invention discloses a waste paper regeneration device. The waste paper regeneration device comprises a paper feeding mechanism, a paper grinding mechanism used for grinding away ink marks on the surface layer of waste paper, a pulp spraying mechanism used for spraying pulp on the surface layer of the waste paper, a compacting and drying mechanism used for compacting and drying paper pulp on the waste paper and a paper discharging mechanism used for guiding recycled paper in the compacting and drying mechanism, wherein all the mechanisms are sequentially connected, and the pulp spraying mechanism is connected with a paper pulp making mechanism. The invention further discloses a paper making method. The method comprises the following steps that waste paper is put into the paper pulp making mechanism for pulping; a whole piece of waste paper is fed into the paper grinding mechanism through the paper feeding mechanism, and surface layer ink marks are ground away; the waste paper with the ink marks on the surface layer being ground off is conveyed into the pulp spraying mechanism, and pulp spraying is conducted on the surface layer of the waste paper; the paper with the surface sprayed with the pulp is conveyed into the compacting and drying mechanism, the paper pulp on the waste paper is compacted and dried, and recycled paper is formed; and the recycled paper in the compacting and drying mechanism is guided out through the paper discharging mechanism. According to the waste paper regeneration device and the paper making method thereof, production cost can be lowered, pollution can be reduced, and waste paper regeneration efficiency can be improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

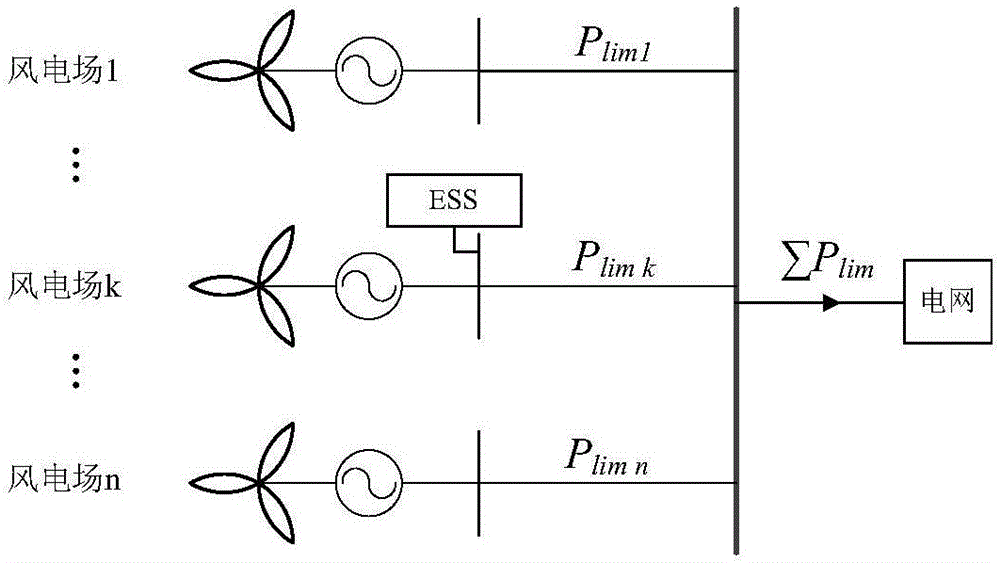

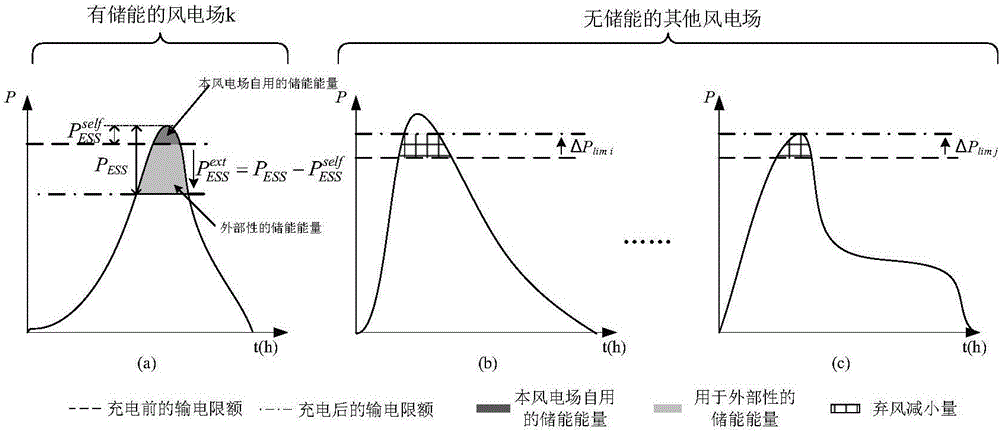

Wind-storage system coordination control strategy for reducing abandoned wind of multiple wind farms by aid of positive externality of stored energy

ActiveCN106786686AReduce wind curtailmentTake advantage ofSingle network parallel feeding arrangementsEnergy storageStored energyEngineering

The invention discloses a wind-storage system coordination control strategy for reducing abandoned wind of multiple wind farms by aid of positive externality of stored energy. The wind-storage system coordination control strategy is characterized by comprising contents of determining distribution principles for power distribution rations of the wind farms in joint external transmission environments with the multiple wind farms; analyzing externality theories of energy storage systems; reducing the abandoned wind of the multiple wind farms by the aid of the positive externality of the stored energy, and the like. The wind-storage system coordination control strategy has the advantages that the positive externality generated by available power and the capacity of the stored energy is sufficiently utilized, relief of the abandoned wind of the local wind farms can be guaranteed, the abandoned wind of the other wind farms can be reduced to the greatest extent, accordingly, the utilization rate of the stored energy can be increased, effects for relieving the abandoned wind by the aid of the stored energy can be optimized, the wind-storage system coordination control strategy is scientific and reasonable and is high in applicability, excellent effects can be realized by the wind-storage system coordination control strategy, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

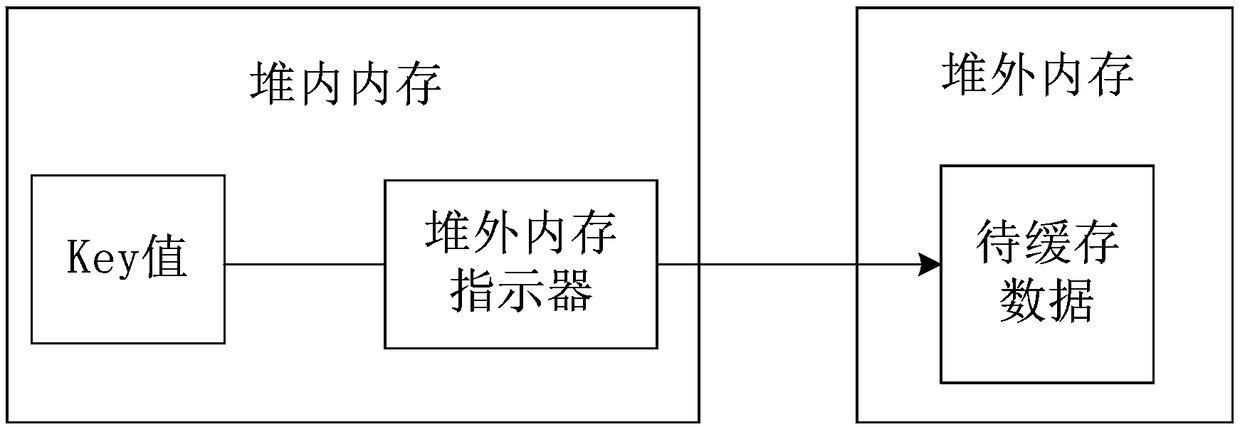

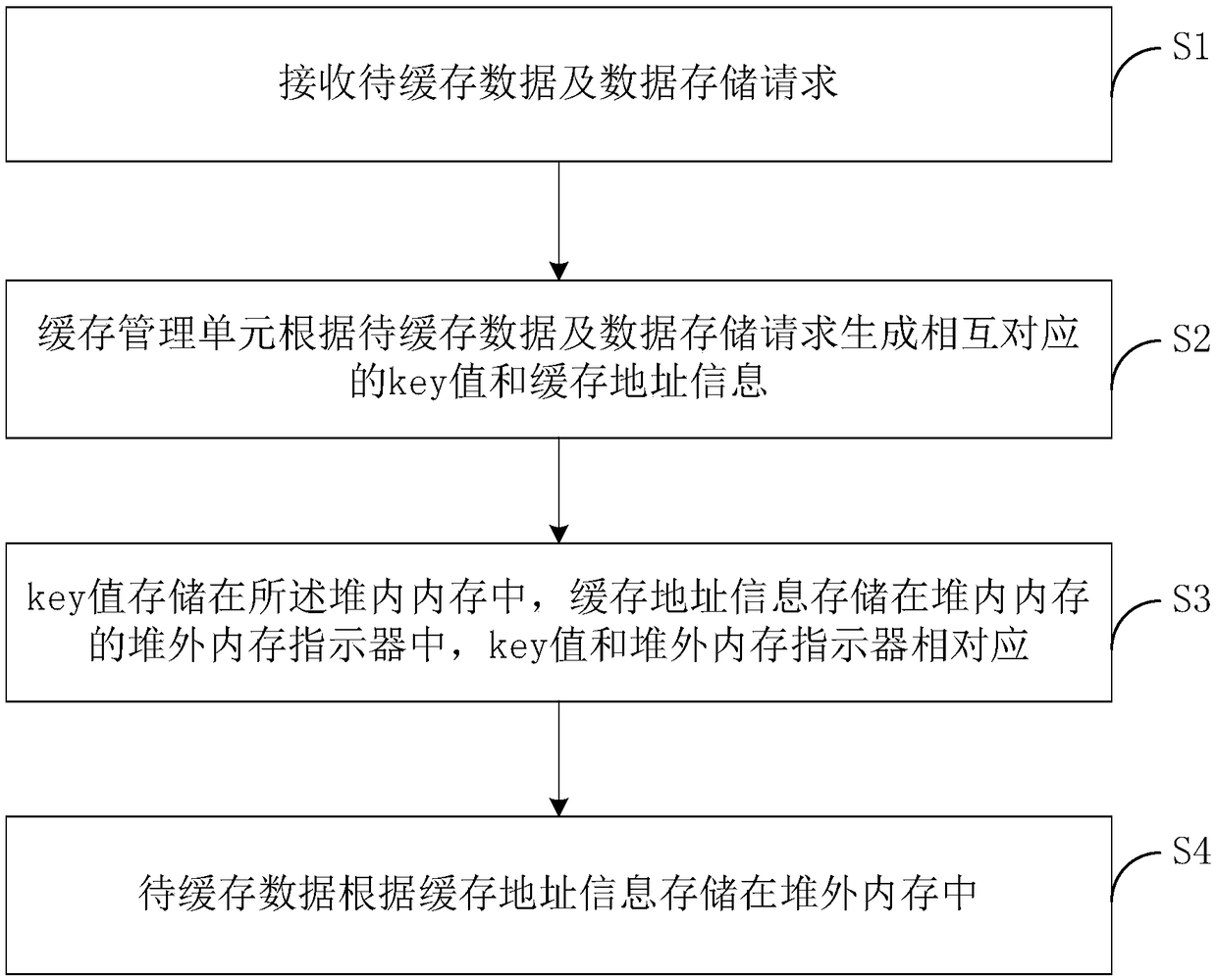

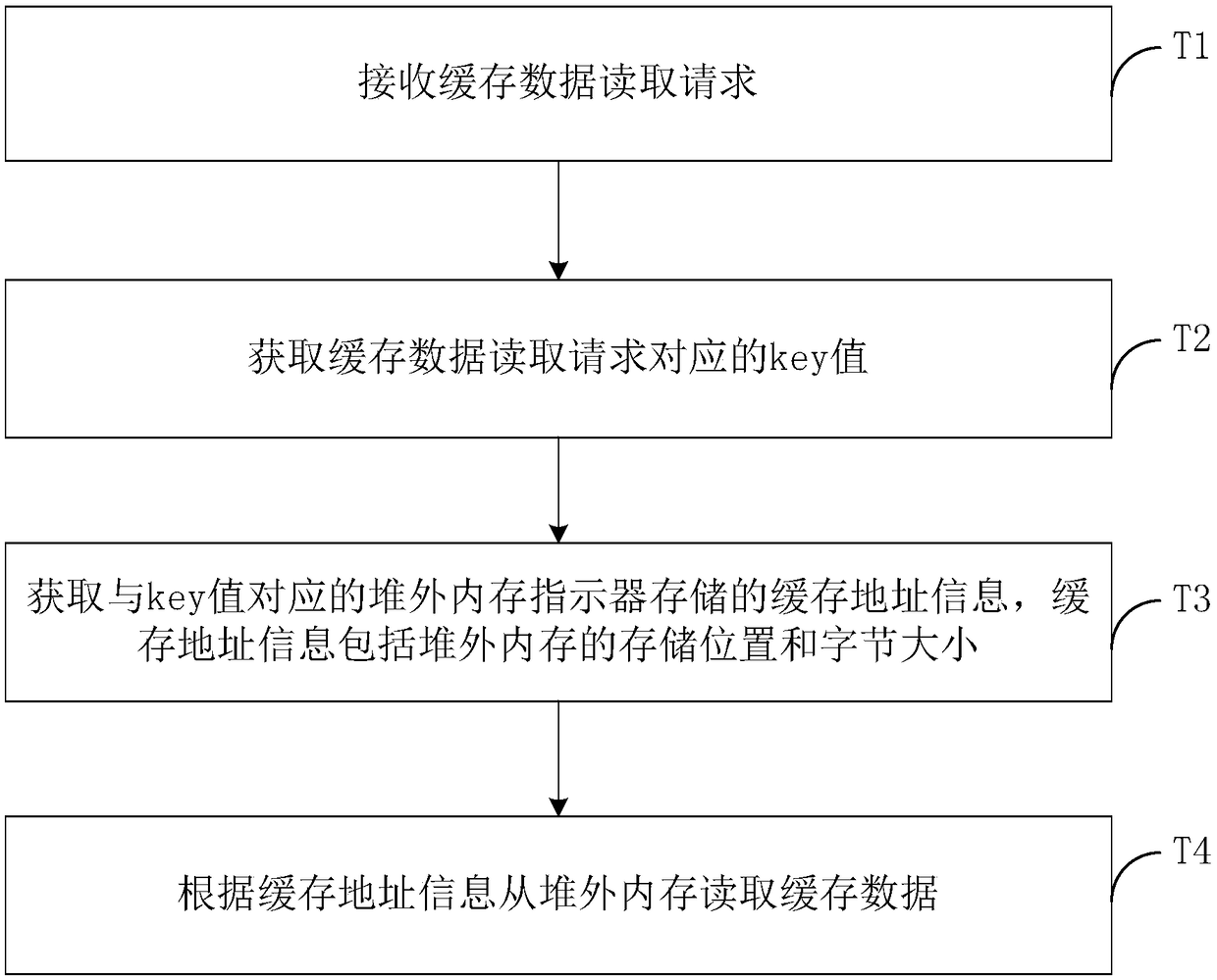

Data cache system, method and computer terminal for java platform

InactiveCN109101554AShorter payback timeLess object copyingSpecial data processing applicationsCache managementData store

The invention relates to a data buffer system, a method and a computer terminal for a Java platform. The system includes a cache, which includes an in-heap memory and an out-of-heap memory, wherein the in-heap memory is used to store key values and out-of-heap memory indicators, key values correspond to out-of-heap memory indicators, and the out-of-heap memory is used to store the data to be cached; a cache management unit which generates a key value and cache address information corresponding to each other according to the data to be cached and the data storage request, wherein the cache address information is the storage address information of the data to be cached in an out-of-heap memory; an out-of-heap memory indicator for storing cache address information. By implementing the invention, the same efficient management of the cache is realized, and the garbage collection time is reduced. Realization of process sharing, fewer object replication between virtual machines; and a fast reboot of persistent storage can be achieved.

Owner:厦门熵基科技有限公司 +1

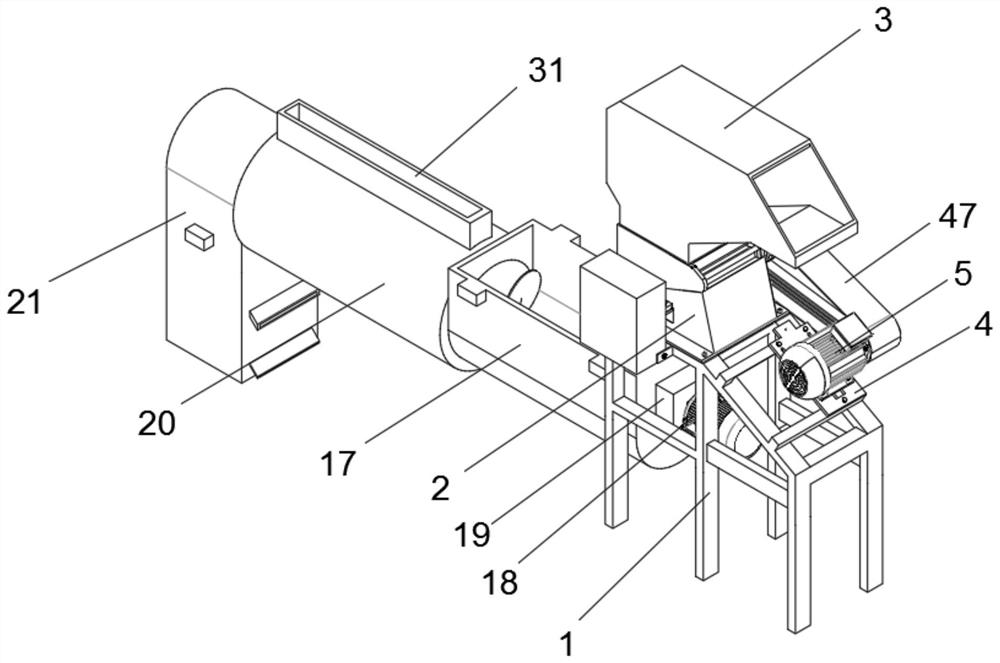

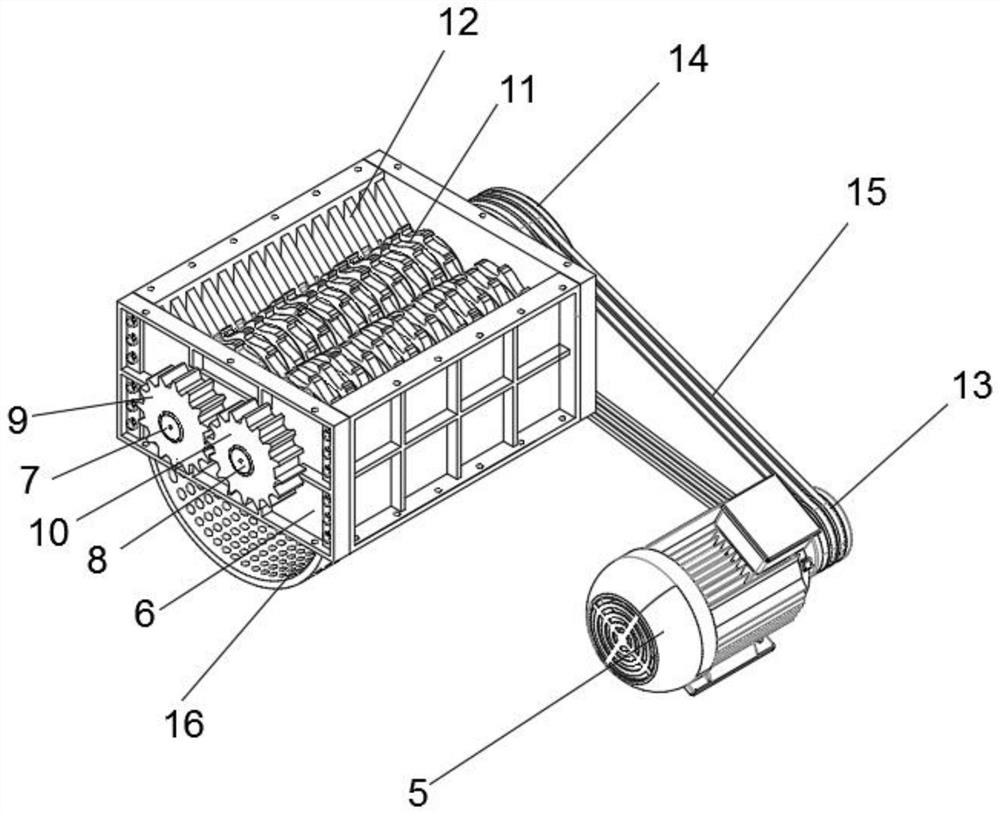

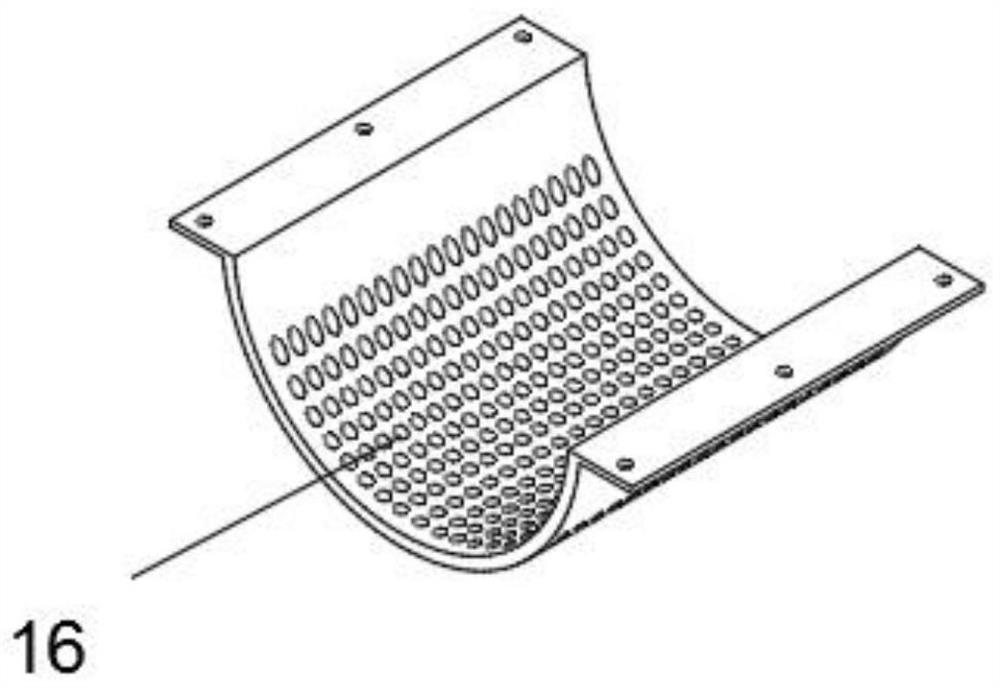

Sorting and crushing device for recycling waste plastics

InactiveCN112078057AImprove qualityImprove processing efficiencyPlastic recyclingDrying gas arrangementsProcess engineeringMechanical engineering

The invention discloses a sorting and crushing device for recycling waste plastics. The sorting and crushing device comprises a bottom frame; crushed plastic fragments are cleaned by arranging a cleaning box; the plastic fragments are fully stirred by utilizing the reverse rotation of an auger and a drying drum; mixed label sticker fragments are blown off while the plastic products are dried by warm air flow; through impurity removal treatment, the purity of the waste plastic fragments and the plastic treatment efficiency are improved, and the situation that the quality of materials obtained after waste plastic regeneration is not high is avoided; a rotary disc and a first screening plate are arranged, and an auger is used for providing power to drive the rotary disc to rotate; and the first screening plate is driven to swing up and down under cooperation of a guide pin and a swing block. The waste plastic screening efficiency is improved; the recycling time is saved; meanwhile the problem that the fragments are accumulated on the surface of the first screening plate is avoided; and the whole device is simple in structure and convenient to use, and can improve the recycling efficiency and the quality of recycled plastic fragments.

Owner:界首市宏达塑业有限公司

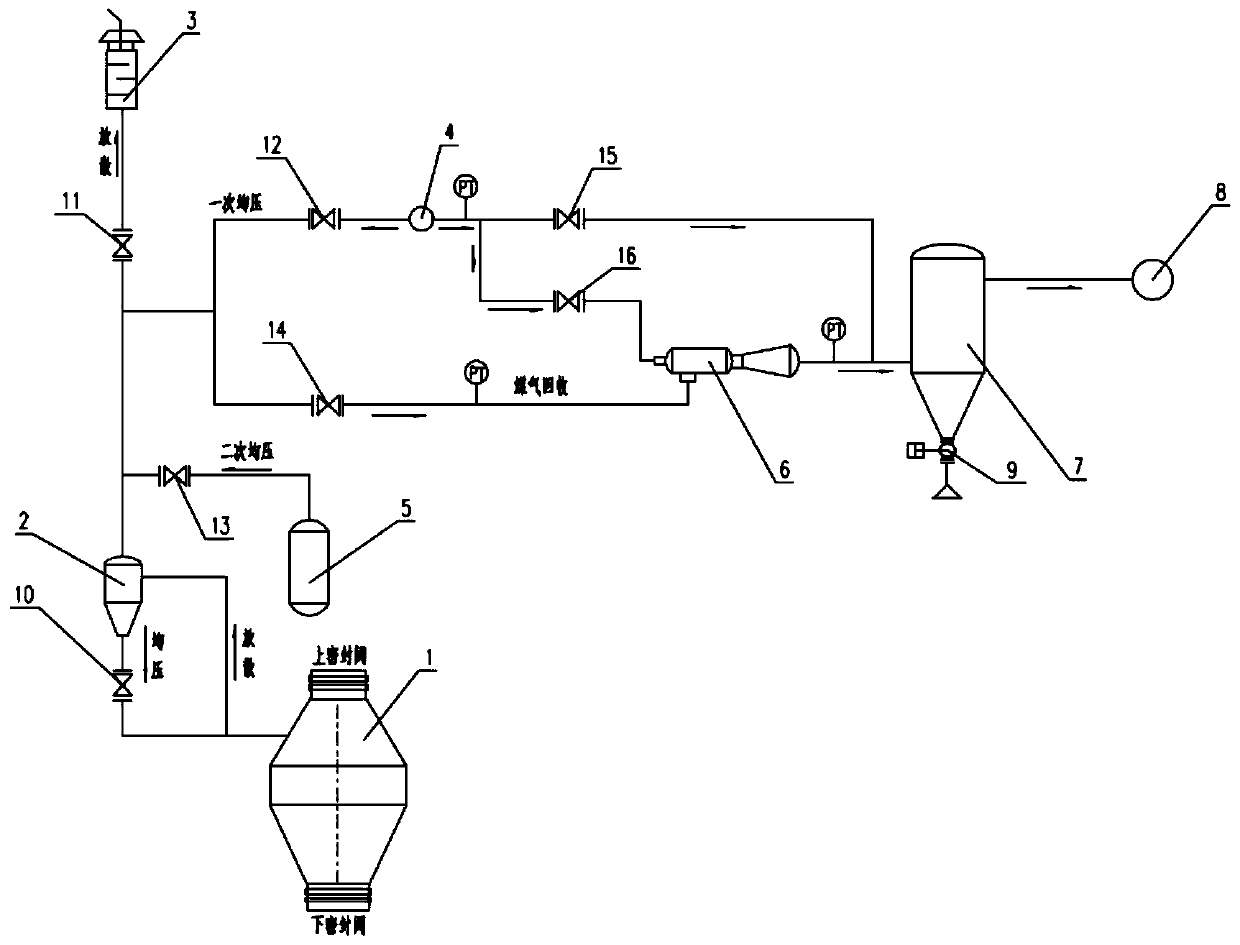

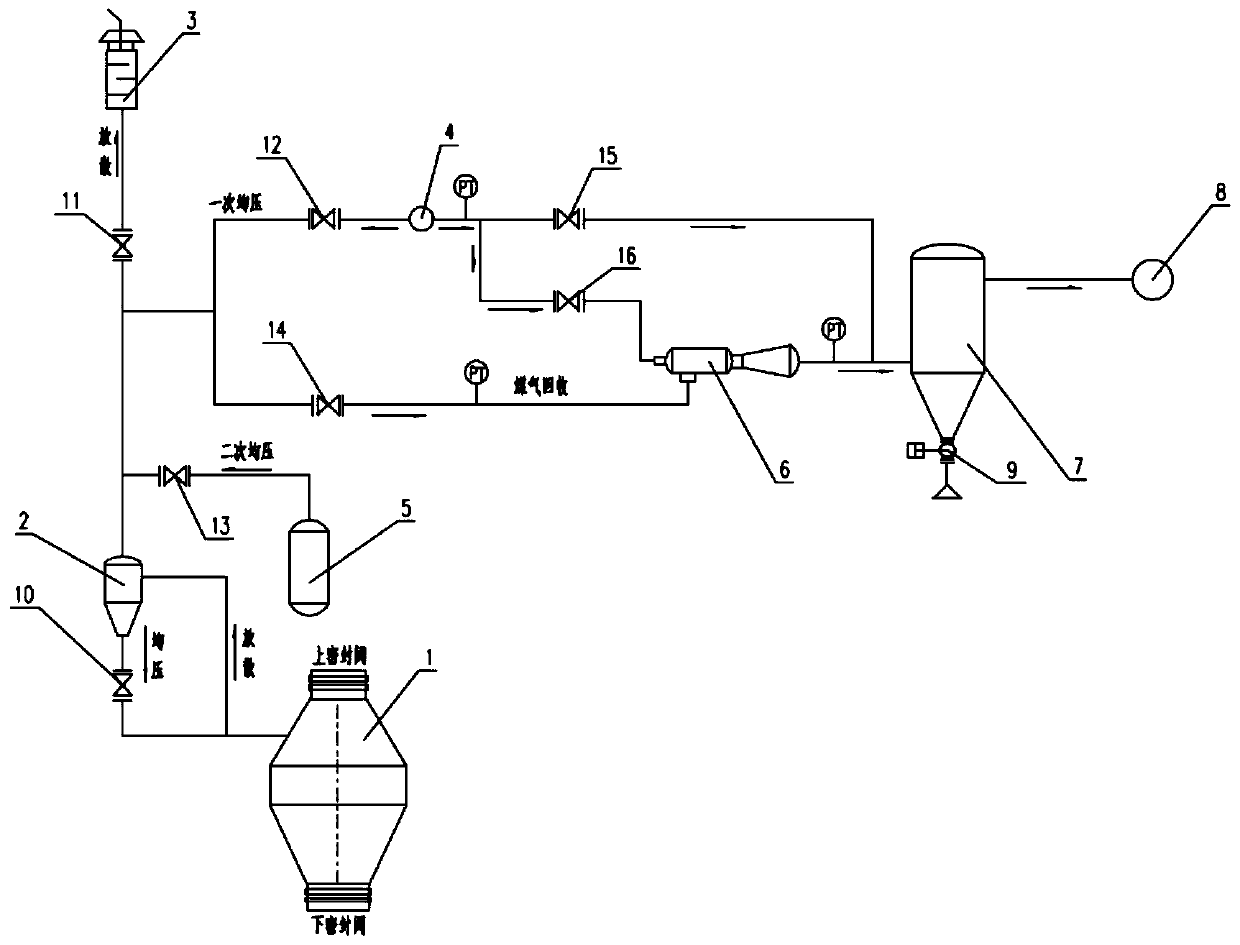

Device for recovering furnace top even pressure diffusion coal gas of blast furnace

The invention discloses a device for recovering furnace top even pressure diffusion coal gas of a blast furnace and belongs to the technical field of blast furnace ironmaking. The device comprises a furnace top material tank, a cyclone dust collector, a muffler, a gas beam push shot gun, a bag-type dust collector, a high pressure nitrogen tank, a primary even coal gas pipeline and a clean coal gaspipe network. When coal gas is recovered, a coal gas recovery and bypass valve is opened, and furnace top even pressure coal gas passes through the cyclone dust collector, the gas beam push shot gunand the bag-type dust collector and then merges into the clean coal gas pipe network. When pressure of the furnace top material tank is lowered to a certain value, a push shot gas valve is opened, thegas beam push shot gun starts to work, the furnace top even pressure coal gas is subjected to the push shot of primary even coal gas, residual low pressure coal gas in the furnace top material tank is conveyed into the bag-type dust collector, is subjected to secondary dust removal and merges into the clean coal gas pipe network, and thus the even pressure diffusion coal gas of the furnace top material tank is recovered. The device for recovering the furnace top even pressure diffusion coal gas has the advantages that the furnace top even pressure diffusion coal gas is recovered overall, theprocess is simple, recovery time is short, and energy saving, environmental protection and low carbon requirements of the iron and steel industry of our country are met.

Owner:BEIJING SHOUGANG INT ENG TECH +1

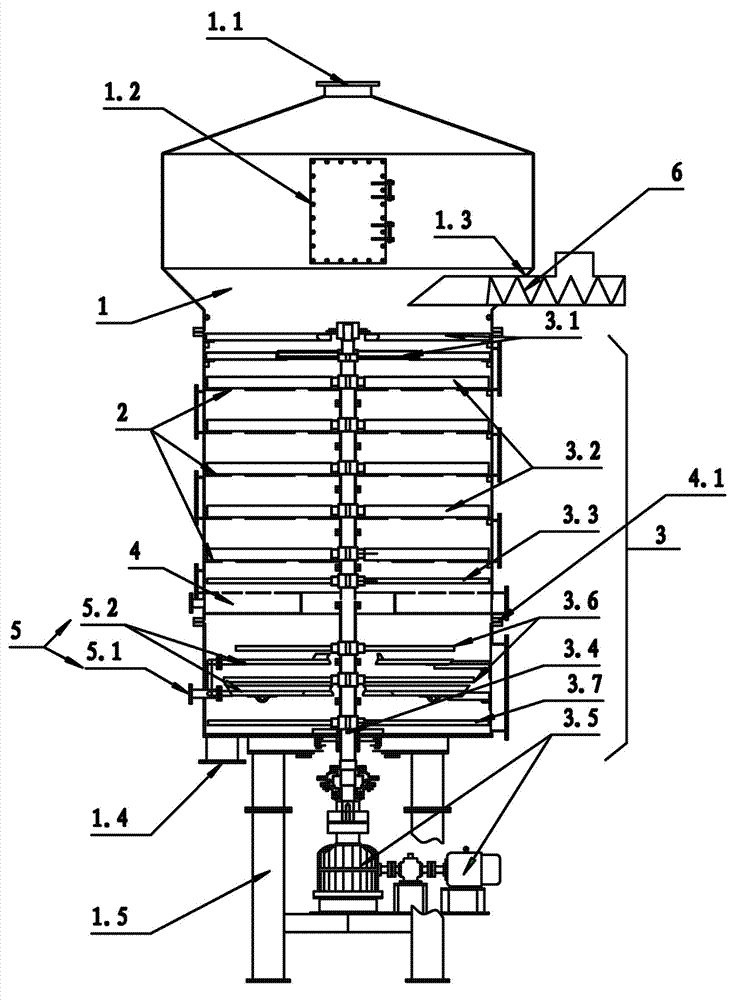

Desolventizing humidifier

ActiveCN102899160AImprove recycling ratesIncrease humidityFatty-oils/fats refiningFatty-oils/fats productionEngineeringSolvent

The invention provides a desolventizing humidifier which comprises a tank body, multi-layer sieve plates, a steam plywood case I and a discharge device. The multi-layer sieve plates are fixed in the tank body, the steam plywood case I is fixed on the tank body and arranged at the bottoms of the multi-layer sieve plates, and the discharge device is arranged in the tank body. The tank body comprises a steam outlet, a feed port and a discharge port, wherein the steam outlet is arranged at the top, the feed port is connected with a feed device, and the discharge port is arranged at the bottom of the tank body. The discharge device comprises a vertical shaft arranged in the center of the tank body and a drive mechanism driving the vertical shaft to rotate. A distribution device, scraper boards, a harrow rod I and a harrow rod III are fixed successively on the vertical shaft from top to bottom. The scraper boards are arranged above and matched with the multi-layer sieve plates, the harrow rod I is introversive and arranged above and matched with the steam plywood case I, and the harrow rod III is extroversive and arranged above and matched with the tank body bottom. Steam is fed into the steam plywood case I, and steam outlets are arranged on the upper portion of the steam plywood case I. Compared with the prior art, the desolventizing humidifier has the advantages of being high in solvent recovery rate and dephenolized cottonseed protein quality.

Owner:济南中棉生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com