Magnesium smelting raw material pellet capable of improving transverse tank magnesium smelting efficiency and preparation method thereof

A raw material and magnesium smelting technology, applied in the field of magnesium smelting, can solve the problems of high content of crude magnesium and silicon, difficult to improve, long magnesium smelting time, etc., and achieve the effects of improving magnesium recovery rate, improving recovery rate and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

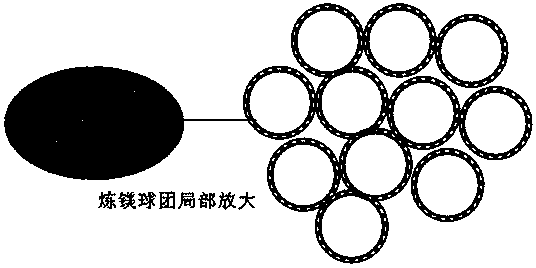

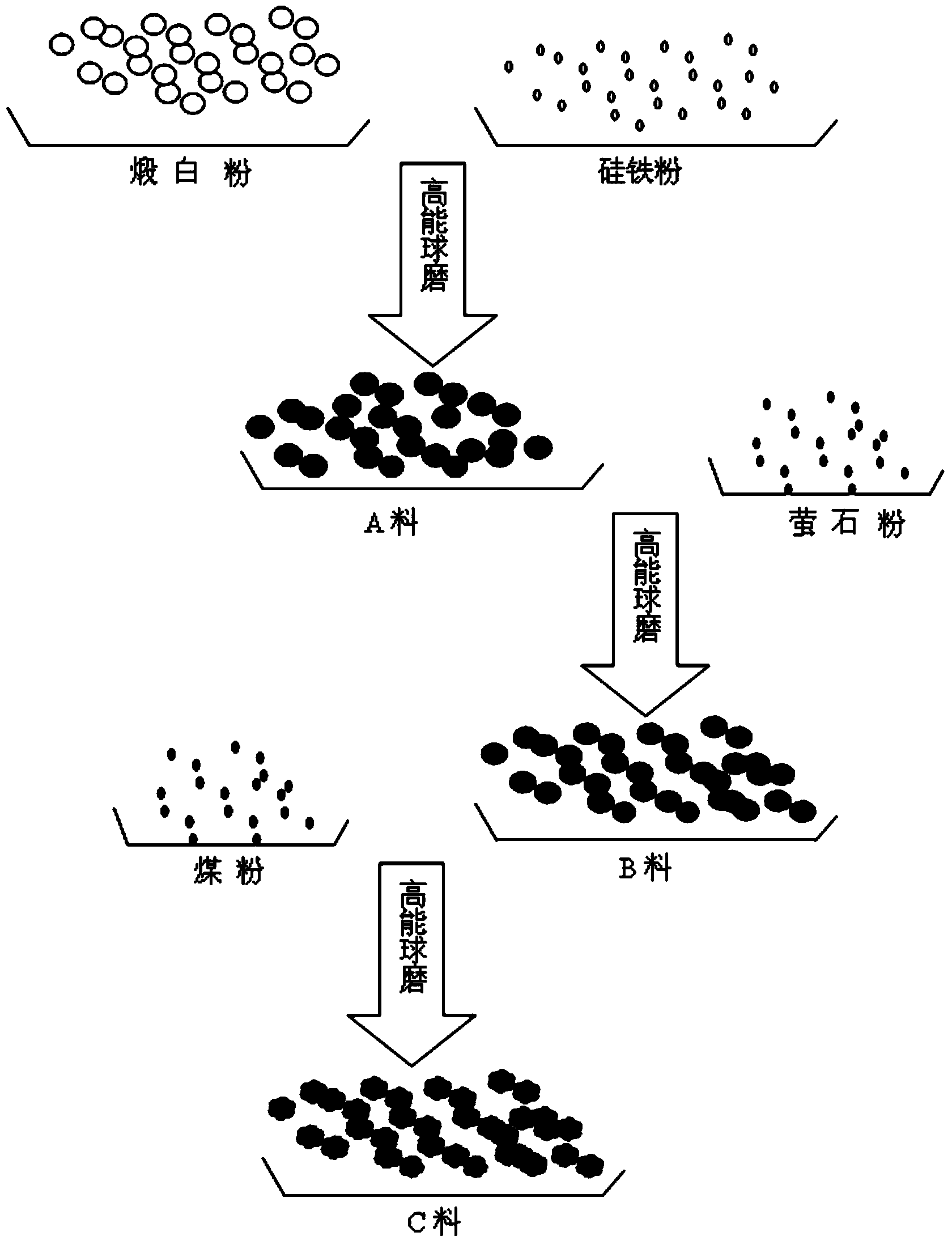

[0038] This embodiment provides a magnesium-smelting raw material pellet that can improve the efficiency of horizontal tank magnesium-smelting. The raw materials of the magnesium-smelting raw material pellet include calcined white powder, ferrosilicon powder and fluorite powder. The magnesium-smelting raw material pellet The raw material of the group also includes coal powder, and the raw material of the described magnesium-smelting raw material pellet is made up of the following raw materials:

[0039] Calcined white powder 400g, ferrosilicon powder 50g, fluorite powder 10g, coal powder 40g.

[0040] Preparation method: use calcined white, ferrosilicon ore, fluorite and coal ore as raw materials, and grind them into fine powder with a ball mill, so that the particle size of calcined white powder is less than 100 mesh, the particle size of ferrosilicon powder is less than 200 mesh, and the particle size of fluorite powder is less than 200 mesh, coal powder particle size is les...

Embodiment 2

[0047] This embodiment provides a magnesium-smelting raw material pellet that can improve the efficiency of horizontal tank magnesium-smelting. The raw materials of the magnesium-smelting raw material pellet include calcined white powder, ferrosilicon powder and fluorite powder. The magnesium-smelting raw material pellet The raw material of the group also includes coal powder, and the raw material of the described magnesium-smelting raw material pellet is made up of the following raw materials:

[0048] Calcined white powder 400g, ferrosilicon powder 25g, fluorite powder 10g, coal powder 65g.

[0049] The preparation method was the same as in Example 1 to obtain 500 g magnesium refining raw material pellets.

[0050] In the kiln, under the vacuum environment of 5Pa, the magnesium-smelting raw material pellets were heated at 1200°C for 10 hours, and 435g of crude magnesium was collected at the crystallizer of the horizontal tank. The recovery rate of crude magnesium reaches 87...

Embodiment 3

[0052] This embodiment provides a magnesium-smelting raw material pellet that can improve the efficiency of horizontal tank magnesium-smelting. The raw materials of the magnesium-smelting raw material pellet include calcined white powder, ferrosilicon powder and fluorite powder. The magnesium-smelting raw material pellet The raw material of the group also includes coal powder, and the raw material of the described magnesium-smelting raw material pellet is made up of the following raw materials:

[0053] Calcined white powder 400g, ferrosilicon powder 30g, fluorite powder 15g, coal powder 55g.

[0054] The preparation method was the same as in Example 1 to obtain 500 g magnesium refining raw material pellets.

[0055] In the kiln, under the vacuum environment of 5Pa, the magnesium-smelting raw material pellets were heated at 1200°C for 10 hours, and 435g of crude magnesium was collected at the crystallizer of the horizontal tank. The recovery rate of crude magnesium reaches 87...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com