Waste paper regeneration device and paper making method thereof

A recycling device and waste paper technology, applied in the direction of textiles and papermaking, raw material pretreatment, etc., can solve the problems of long production time and high production cost, and achieve the effect of less rapid drying, low manufacturing cost and good environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

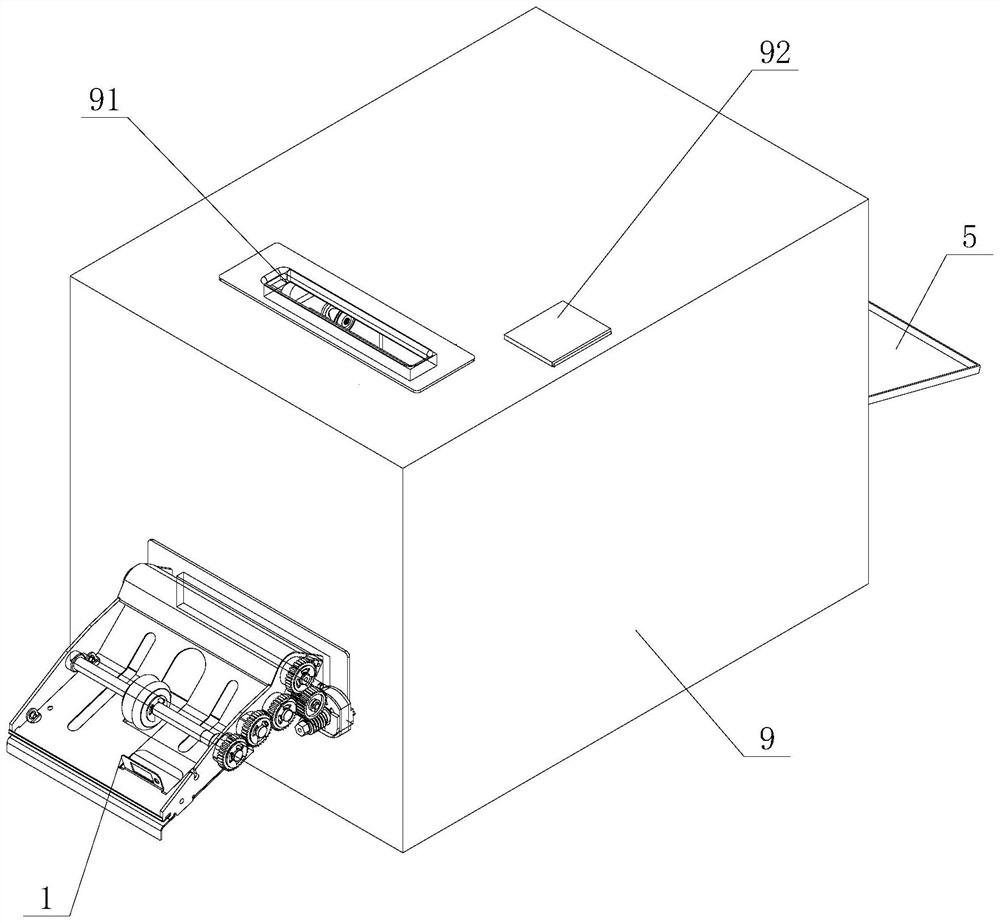

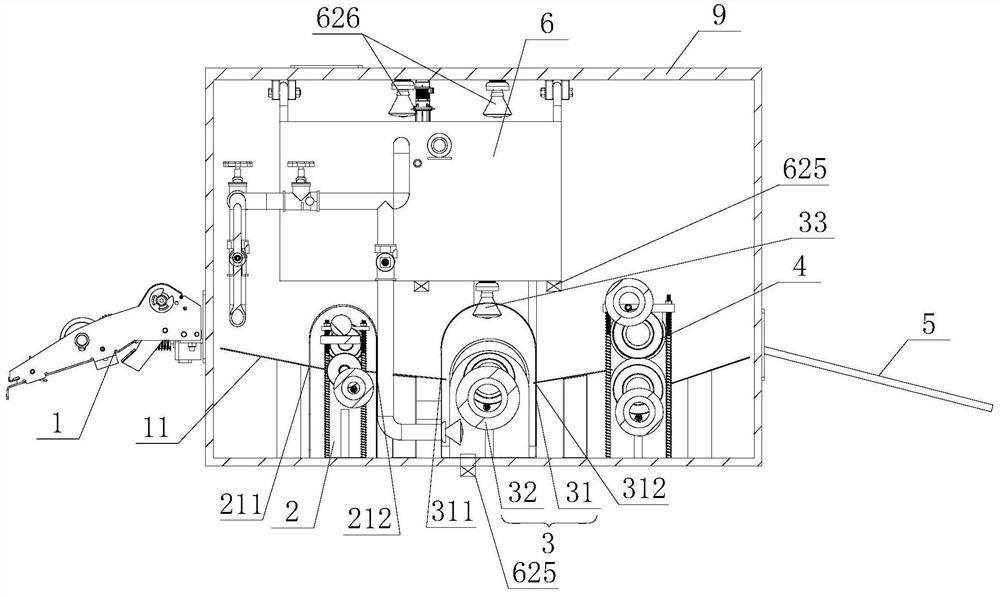

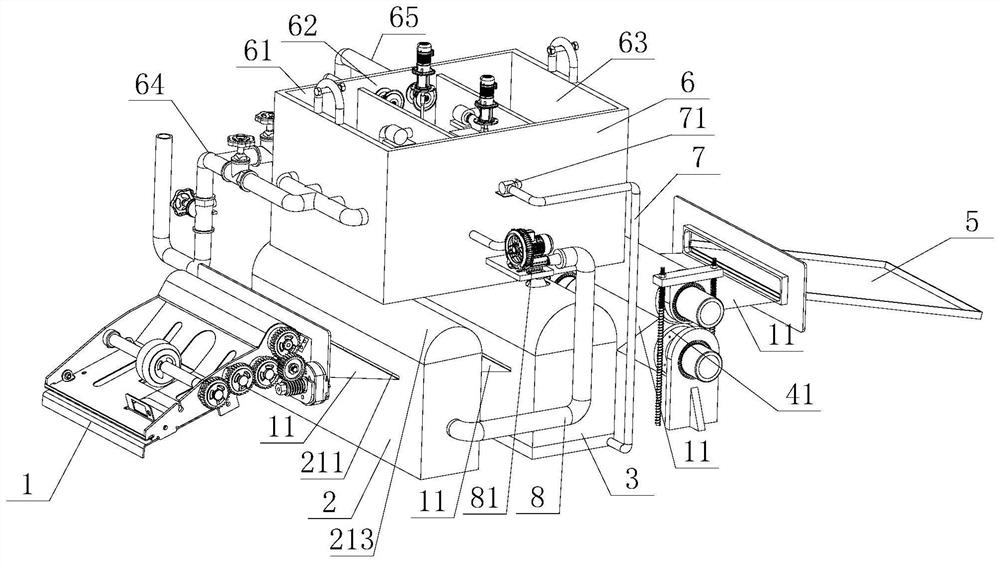

[0041] Figure 1 to Figure 13An embodiment of the waste paper recycling device of the present invention is shown. The waste paper recycling device includes a paper feeding mechanism 1 connected in sequence, a paper grinding mechanism 2 for grinding ink on the surface of the waste paper, and a paper grinding mechanism 2 for grinding the surface of the waste paper. The spraying mechanism 3 for spraying, the compacting and drying mechanism 4 for compacting and drying the pulp on the waste paper, and the paper output mechanism 5 for exporting the recycled paper in the compacting and drying mechanism 4, the spraying mechanism 3 A pulp making mechanism 6 is connected. The paper making process using this waste paper recycling device: firstly, put the waste paper into the pulp making mechanism 6 for pulping, and the pulp making mechanism 6 supplies pulp to the spraying mechanism 3; secondly, the whole waste paper is fed into In the paper grinding mechanism 2, the ink on the surface o...

Embodiment 2

[0056] A paper making method of a waste paper recycling device, comprising the steps of:

[0057] S1: Pulping: put the waste paper into the pulping mechanism 6 for pulping, and the pulping mechanism 6 supplies pulp to the spraying mechanism 3;

[0058] S2: Grinding ink marks: the whole waste paper is fed into the grinding mechanism 2 through the paper feeding mechanism 1, and the surface ink marks are removed;

[0059] S3: Shotcrete: the waste paper after the surface ink is removed is sent to the spray mechanism 3, and the surface layer of the waste paper is sprayed;

[0060] S4: compacting and drying: the paper after spraying on the surface layer is sent to the compacting and drying mechanism 4, and the pulp on the waste paper is compacted and dried to form recycled paper;

[0061] S5: exporting: the recycled paper in the compacting and drying mechanism 4 is exported through the paper output mechanism 5 .

[0062] This paper making method forms recycled paper by first grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com