Device for recovering furnace top even pressure diffusion coal gas of blast furnace

A technology for releasing gas and high-pressure nitrogen, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as environmental pollution, waste of resources, difficult recycling, etc., to reduce gas condensation and water condensation, speed up recovery, and shorten gas recovery time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

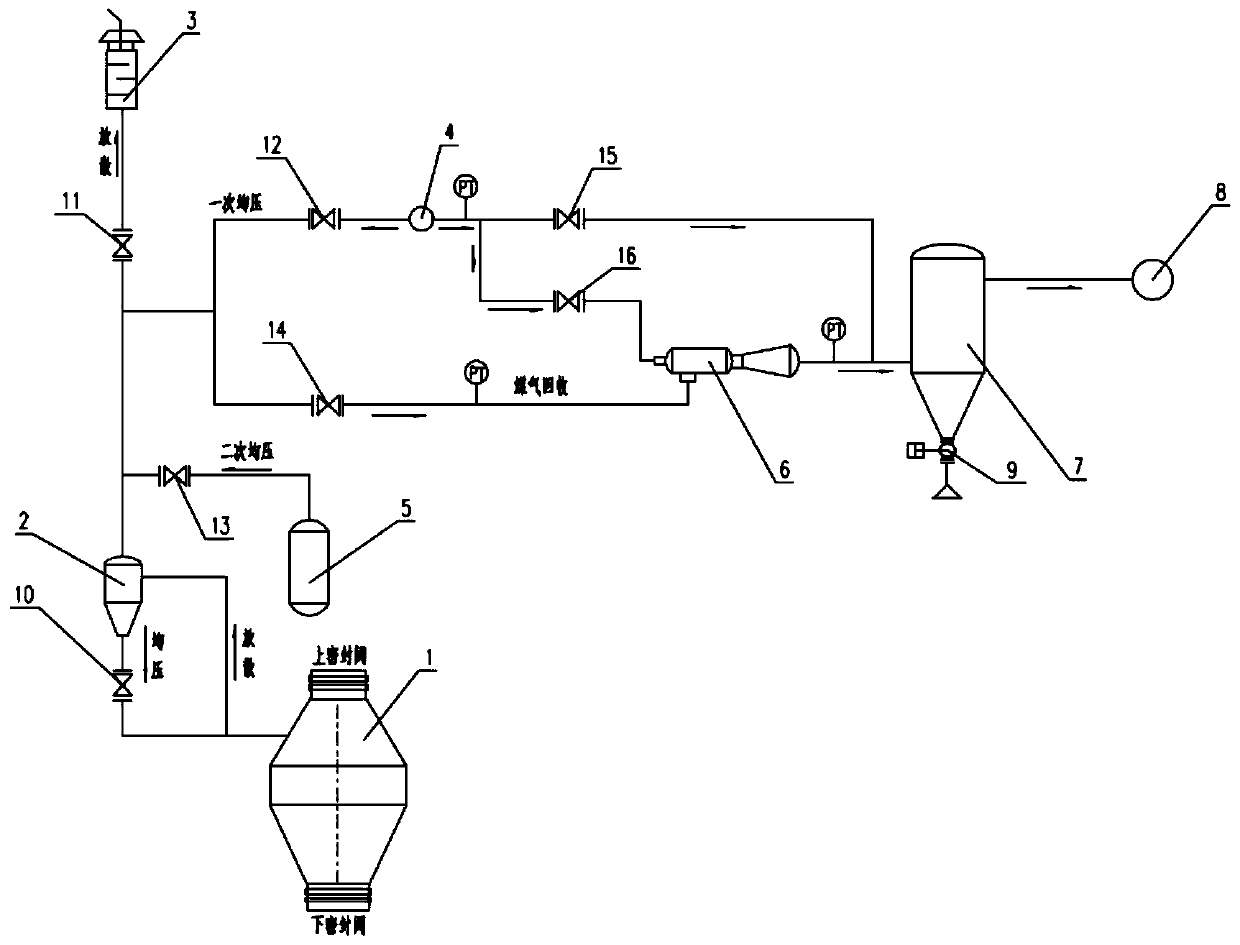

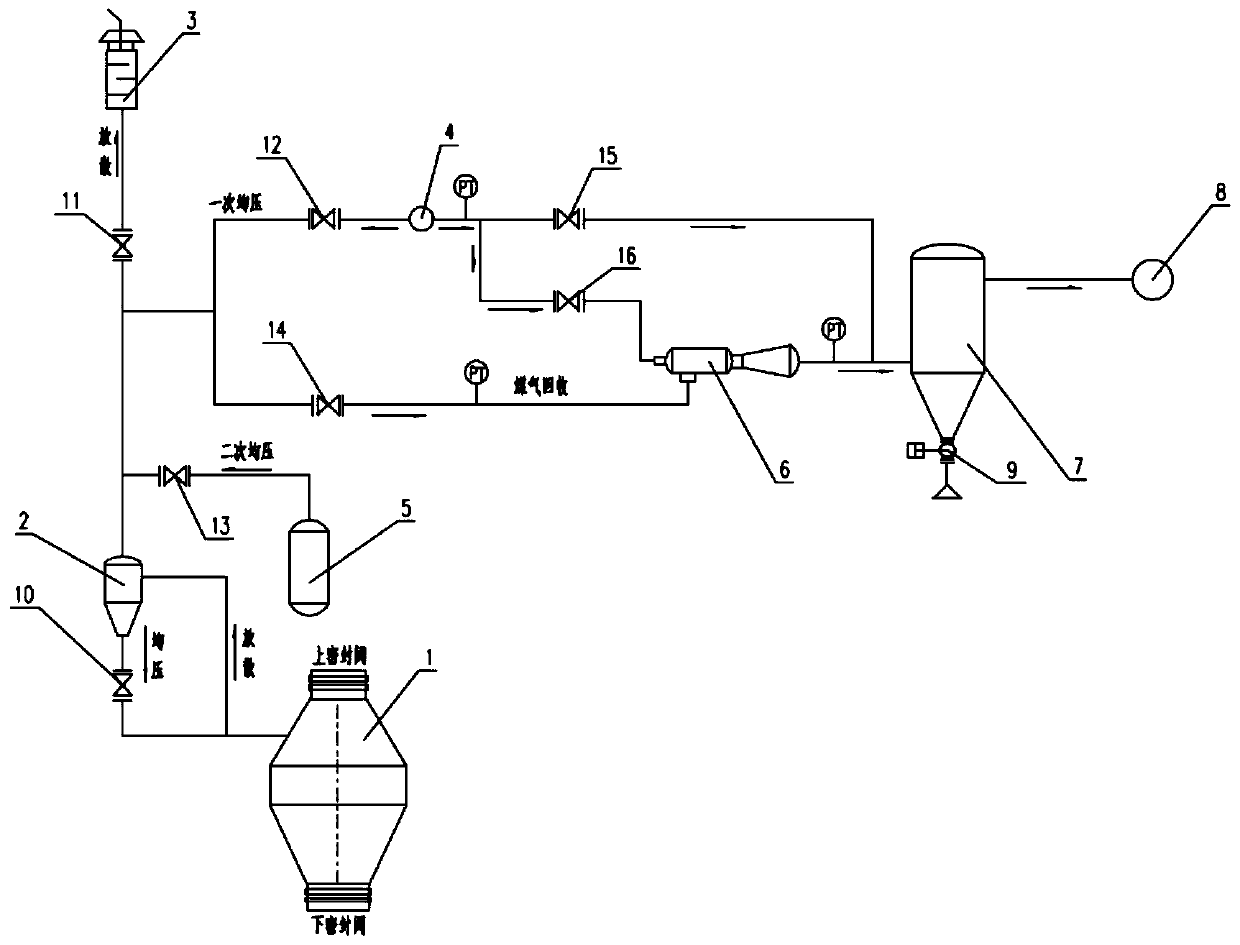

[0023] Such as figure 1 Shown is a device for recovering blast furnace roof equalizing pressure and releasing gas, including a furnace top material tank 1, a cyclone dust collector 2, a silencer 3, an air beam propelling gun 6, a bag filter 7, a high-pressure nitrogen tank 5, a Average gas pipeline 4 and net gas pipeline network 8. The furnace top material tank 1 is provided with an equal pressure release port, the cyclone dust collector 2 is provided with an upper intake and exhaust port, a lower intake and exhaust port, and a side intake and exhaust port, and the gas beam propelling gun 6 is provided with a uniform gas inlet , furnace top gas inlet and mixed gas outlet; the pressure equalization vent of furnace top material tank 1 is connected with the side inlet and exhaust ports and the lower part of cyclone dust collector 2 respectively through pipelines, furnace top material tank and cyclone dust collector 2. A pressure equalizing valve 10 is provided on the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com