Sorting and crushing device for recycling waste plastics

A technology of waste plastic and crushing device, which is applied in plastic recycling, recycling technology, mechanical material recycling and other directions, can solve the problems of low screening efficiency, low quality of waste plastic after regeneration, easy accumulation of debris, etc. The effect of low quality, improved efficiency and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described below in conjunction with examples, as will be described, as described herein, only the embodiments of the invention, not all embodiments. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

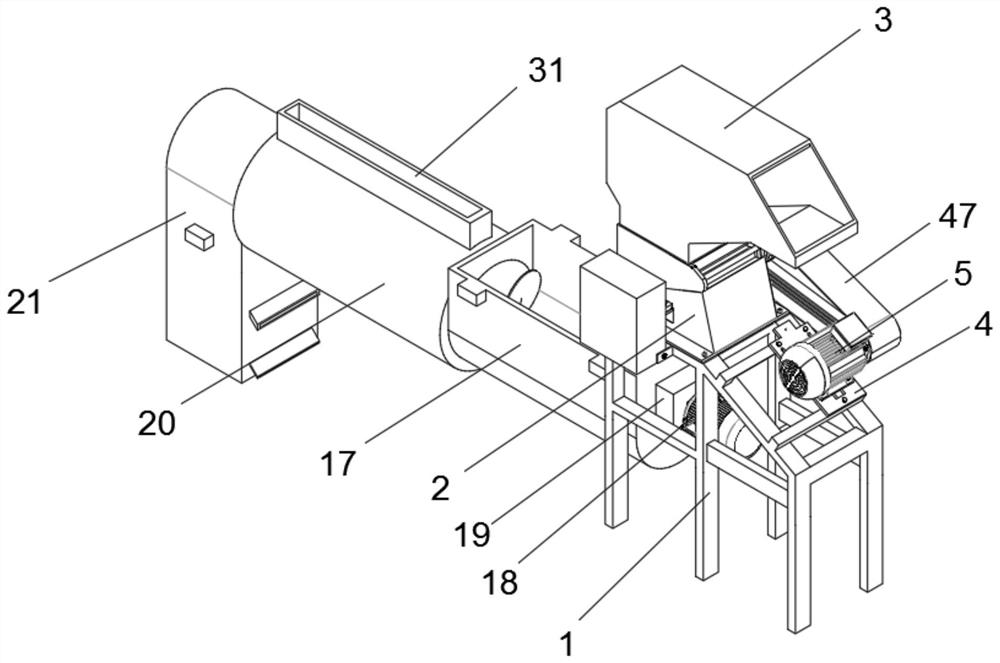

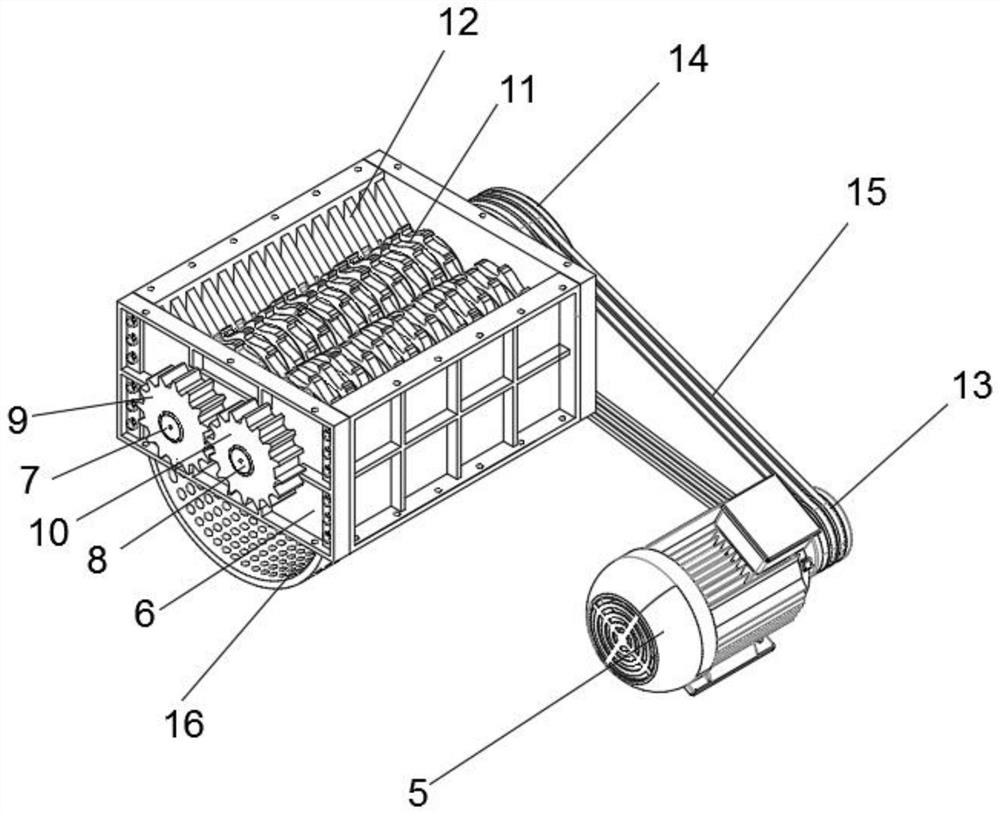

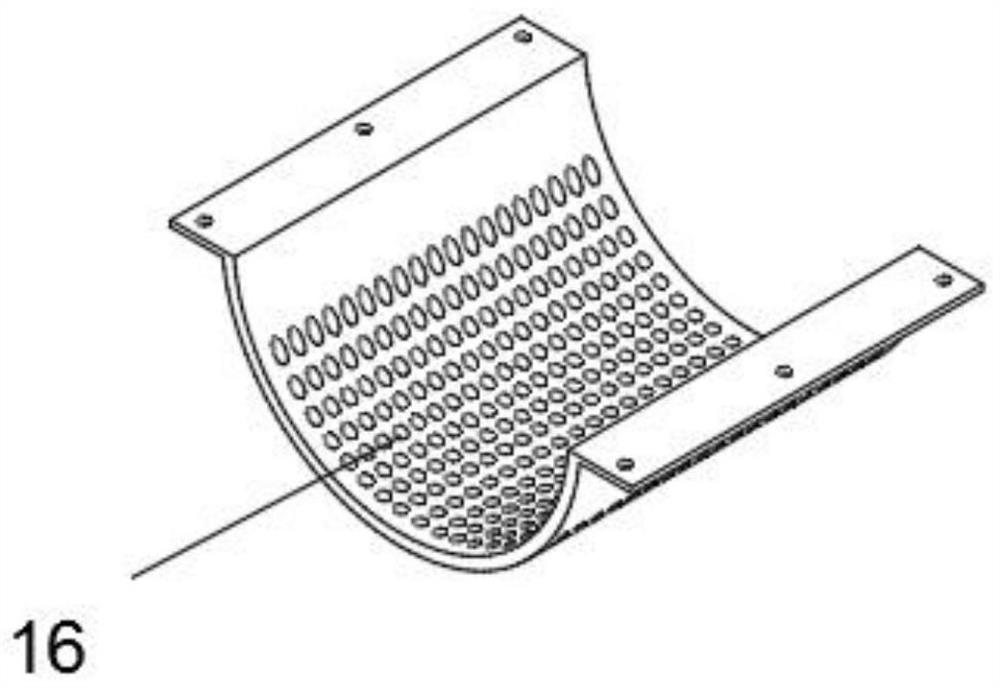

[0039] See Figure 1-9 As shown in A sorting crushed plastic waste recycling apparatus, comprising a chassis 1, the protective casing 2, the hopper 3, the mounting plate 4, the motor 5 crushing, crushing housing 6, the drive shaft 7, from shaft 8, the driving gear 9, the driven gear 10, the rotary blade 11, the fixed blade 12, the first pulley 13, second pulley 14, a first belt 15, the filter screen 16, a cleaning box 17, a transport motor 18 , reducer 19, the drying box 20, the feed box 21, auger 22, the drying cylinder 23, the fixed shaft 24, the limit wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com