Spraying device with coating recovery structure

A spraying device and paint recycling technology, which is applied in the direction of spraying devices, can solve the problems of wasting more manpower and time, inconvenient paint cleaning, and increasing the difficulty of recycling, so as to shorten the recycling time and reduce the time for installing the receiving box , recycling simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

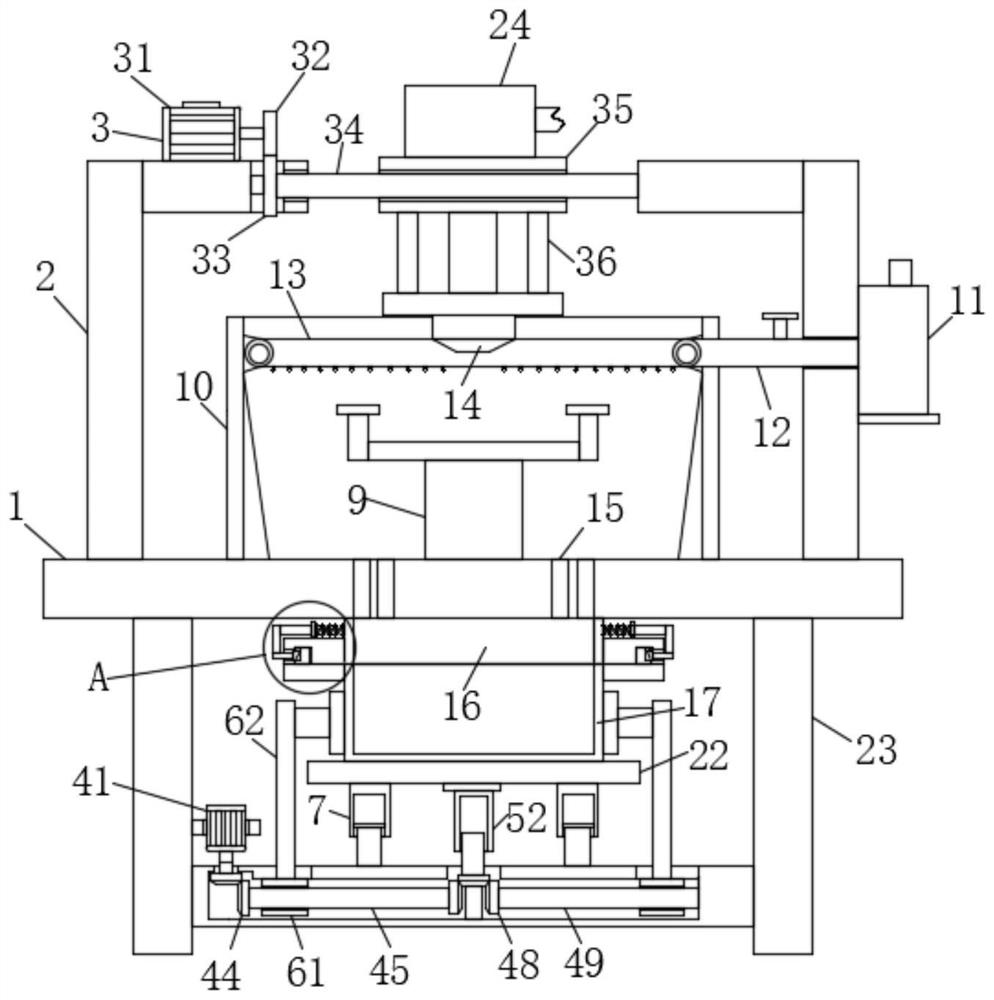

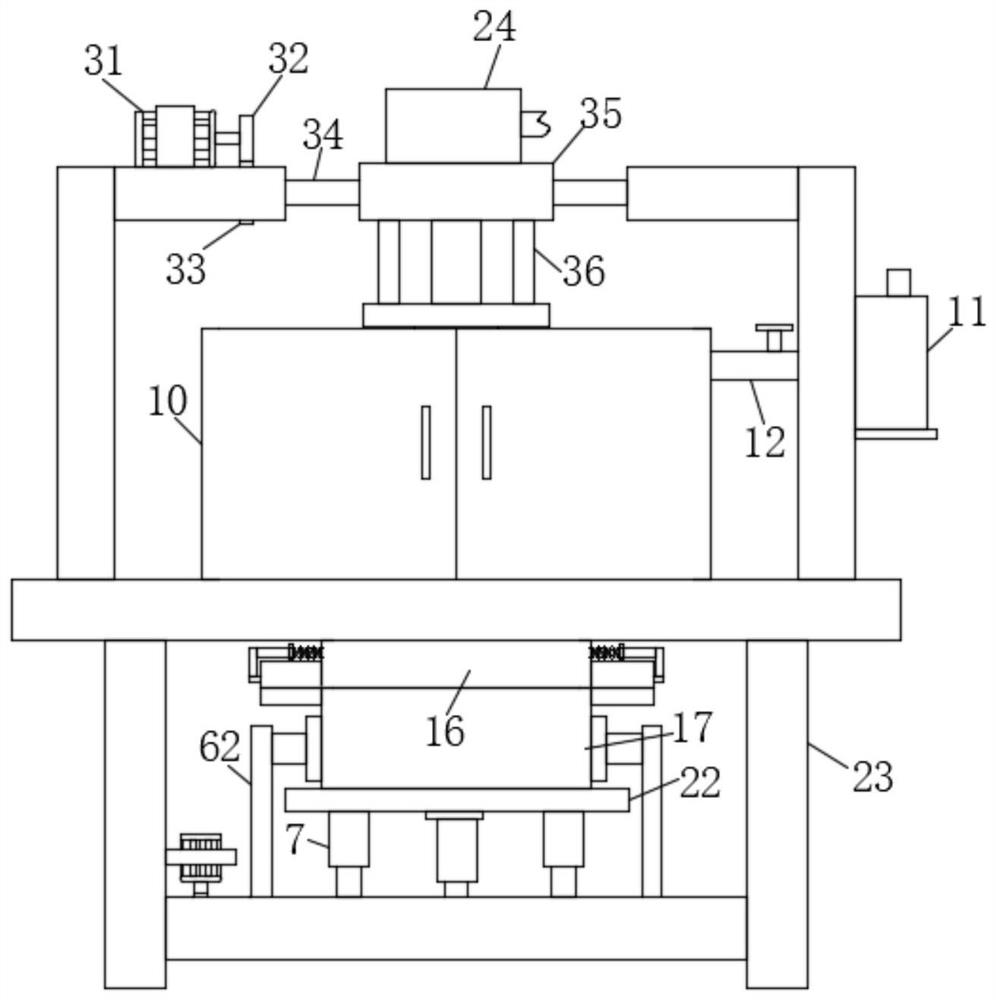

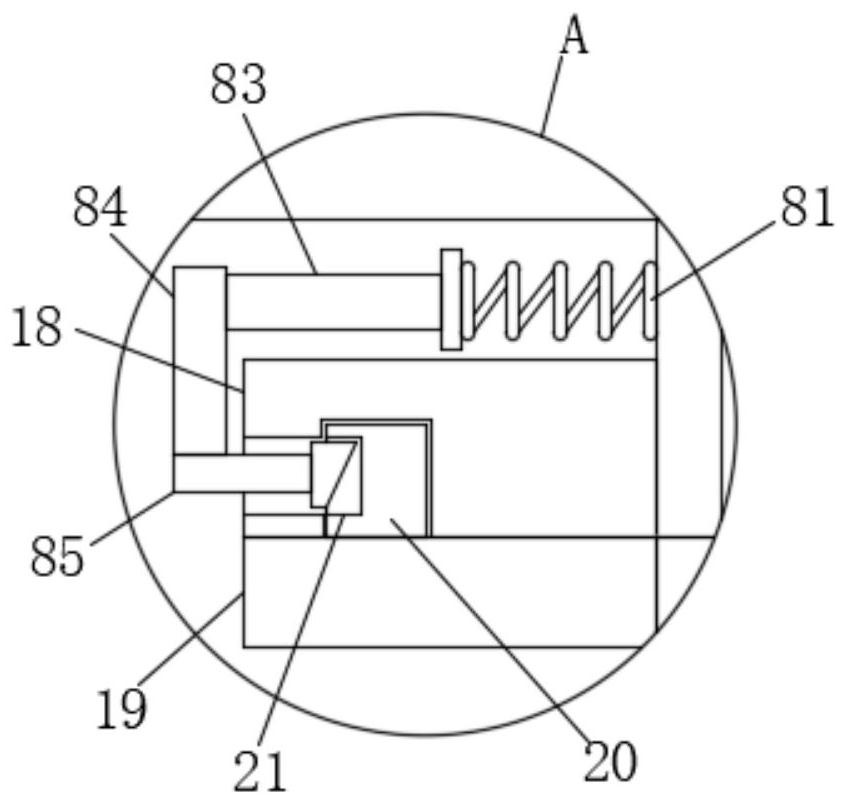

[0025] Example: such as Figure 1-6 As shown, a spraying device with a paint recovery structure of the present invention includes a fixed platform 1, and both sides of the upper end of the fixed platform 1 are fixedly connected to the fixed frame 2, and the upper ends of the two fixed frames 2 are fixedly connected by an adjustment mechanism 3 , the upper end of the adjustment mechanism 3 is equipped with a transport box 24, and the lower end of the adjustment mechanism 3 is equipped with a nozzle 14. The adjustment mechanism 3 provided can facilitate the adjustment of the position of the nozzle 14 and facilitate the use of the nozzle 14. The middle part of the upper end of the fixed table 1 Fixedly connect the limit frame 10, the middle part of the upper end of the fixed table 1 is fixedly connected with the processing table 9, the middle part of the fixed table 1 is provided with a number of communication ports 15, the middle part of the lower end of the fixed table 1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com