Safe and fast driving method for large-section open-off cut time-by-time tunneling

A large-section, roadway-forming technology, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of low efficiency and achieve the effects of increasing the operating rate, saving recovery time, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

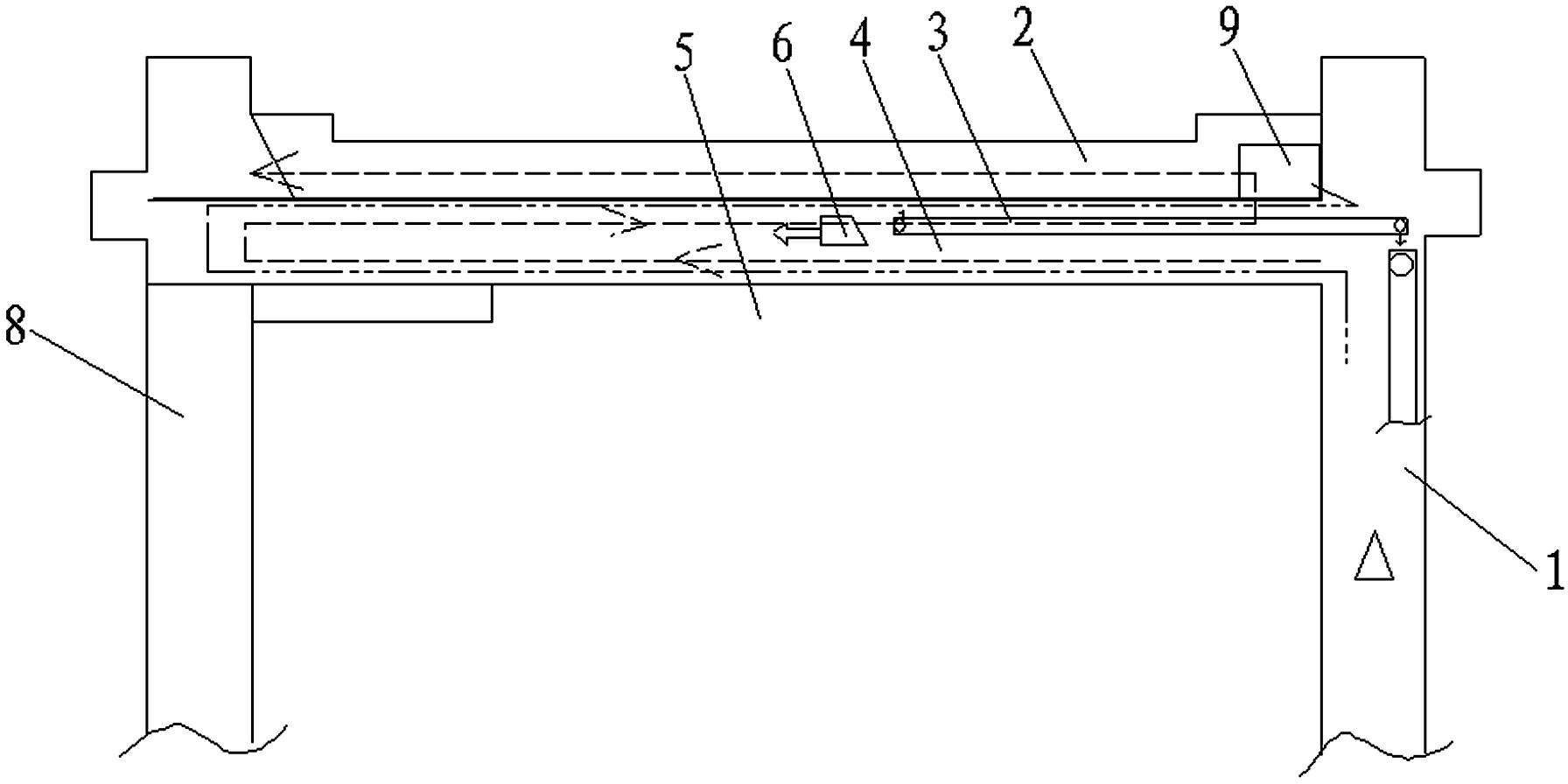

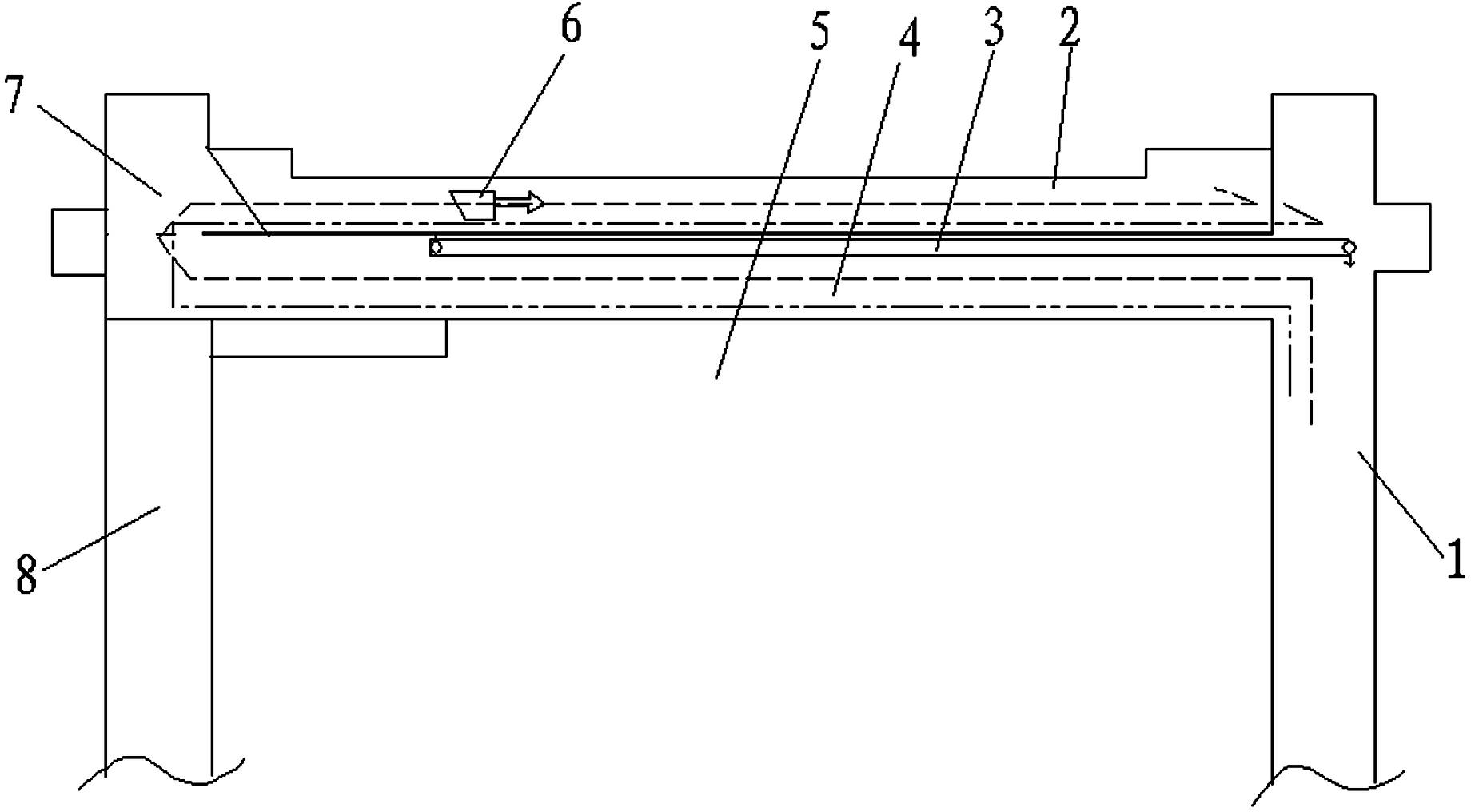

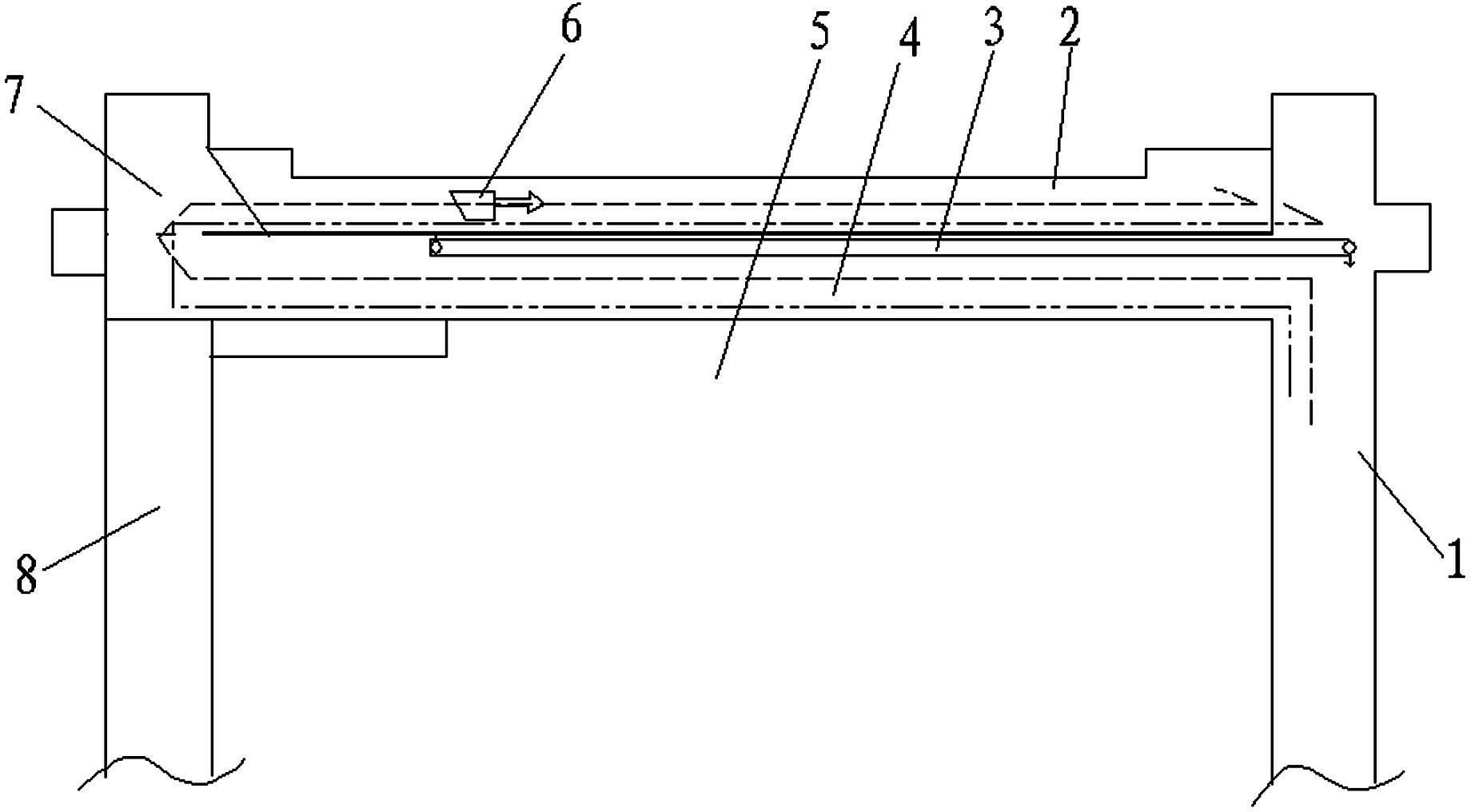

[0020] Such as figure 2 As shown in Fig.

[0021] In a coal mining area, the design working face 5 is 180 meters long. The right side of the working face 5 is the air inlet lane, and the left side is the return air lane 8 which is under design but not excavated. One side of the air inlet lane 1 begins to excavate along the cut-out guide tunnel 4, which is 4.0 meters wide. At the same time, follow up the laying track and slide 3 to transport the coal out. After the cut-out guide tunnel 4 is dug in place , to the larger side of the cutting hole to be constructed at the grinding angle 7, the coal cutter 6 turns at the grinding angle 7 and adjusts the machine to cut coal at 90 degrees so that the tunneling unit enters the return airway at position 8, and adjusts the machine again to cut at 90 degrees Coal makes the unit enter the left end of the large side 2 of the eye brush to be cut. The width of the large side 2 of the eye brush is 2.2 meters, and then start to excavate the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com