Preparation method of magnetic nanometer carrier for immobilized enzyme

A technology of magnetic nanocarriers and immobilized enzymes, which is applied in the directions of being immobilized on or in inorganic carriers, immobilized on/in organic carriers, etc., can solve the problems of easy agglomeration of magnetic nanocarriers, harsh preparation conditions, and enzyme activity. Serious loss and other problems, to achieve the effect of high immobilization rate, simplified preparation steps and processes, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

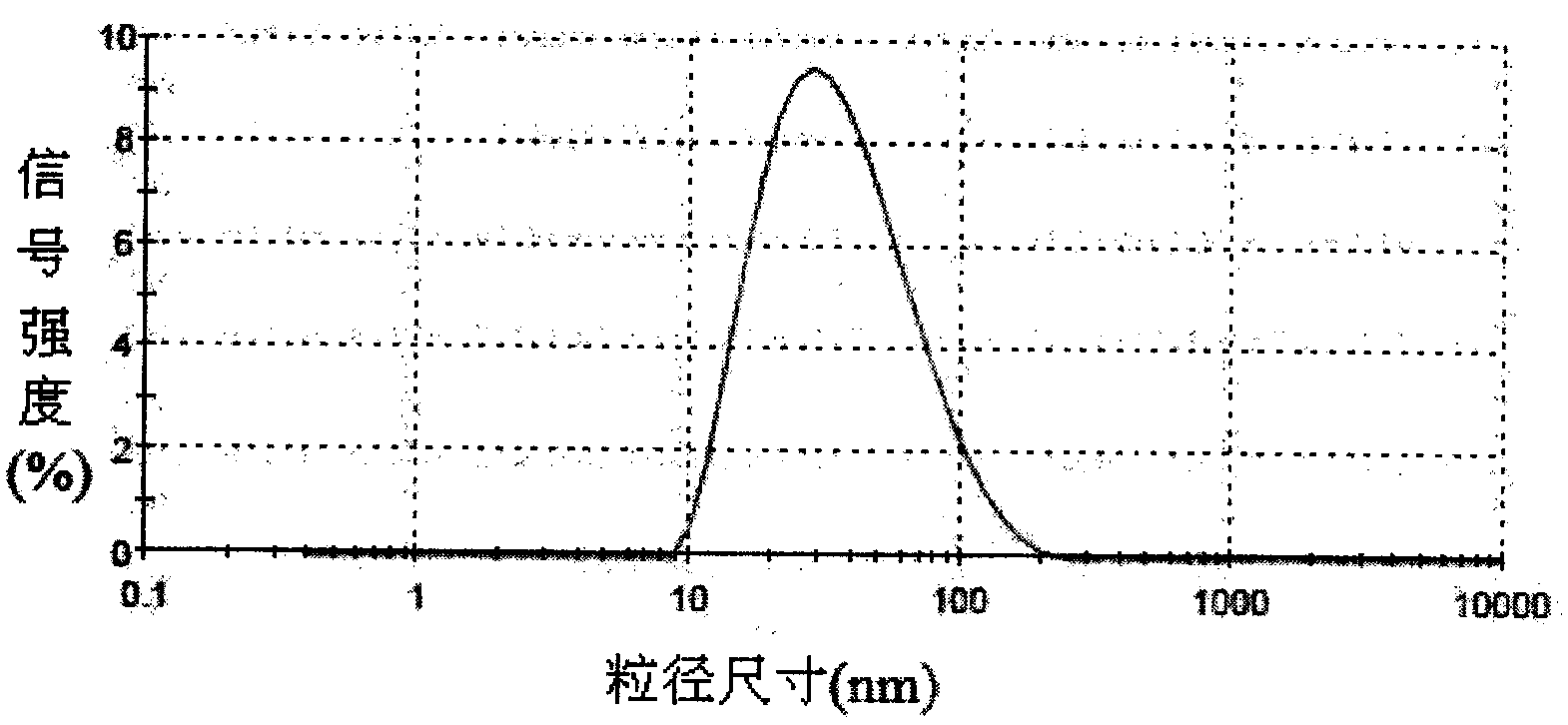

Embodiment 1

[0025] Take two conical flasks, add 10 mL of deionized water to one of the flasks, pass N 2 After removing the air in the triangular flask and water, add 0.152g FeSO respectively 4 and 0.400gFe 2 (SO4) 3 , after completely dissolving, add 10g CTAB, 20mL isopropanol and 30mL cyclohexane respectively, fully stir until completely dissolved to form stable W / O Fe Fe 2+ / Fe 3+ Inverted microemulsion; add 3.75 mL of deionized water to a separate bottle, pass N 2 After removing the air in the conical flask and the water, add 1.25 mL of 25% ammonia water, 5 g CTAB, 10 mL of isopropanol and 15 mL of cyclohexane, respectively, and stir thoroughly until completely dissolved to form a stable W / O type ammonia water inverse microemulsion; then add 1 mL of / min flow rate, the ammonia water inverse microemulsion was added dropwise to Fe 2+ / Fe 3+ In the reversed-phase microemulsion, after all the additions are completed, continue to stir the reaction for 30 minutes until the reaction is ...

Embodiment 2

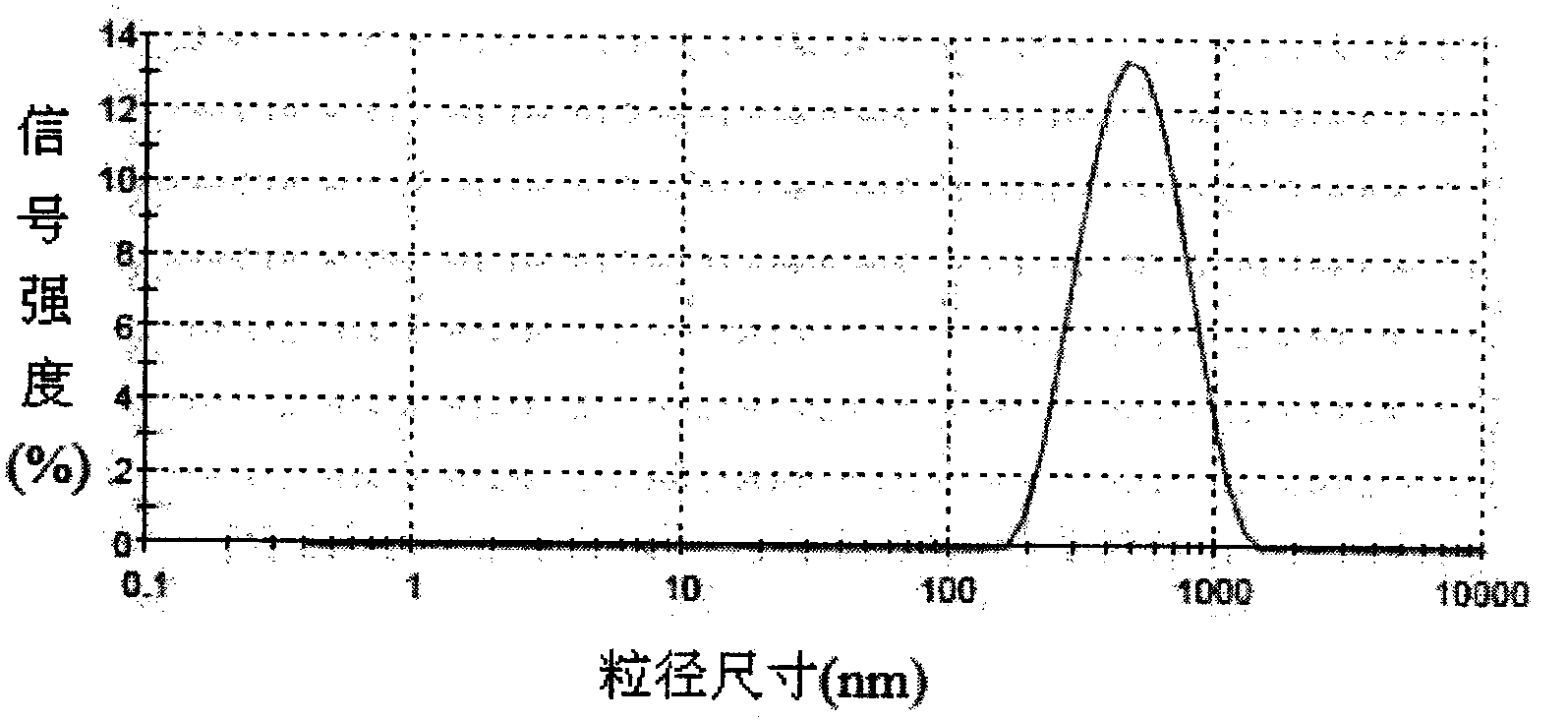

[0028] Take two conical flasks, add 10 mL of deionized water to one of the flasks, pass N 2 After removing the air in the triangular flask and water, add 0.260g FeSO respectively 4 ·6H 2 O and 0.562gFe 2 (SO 4 ) 3 ·9H 2 O, after completely dissolving, add 10g CTAB, 20mL isopropanol and 30mL carbon tetrachloride respectively, stir fully until completely dissolved to form stable W / O Fe 2+ / Fe 3+ Inverted microemulsion; add 5.0 mL of deionized water to a separate bottle, pass N 2 After removing the air in the conical flask and the water, add 0.32g NaOH, after dissolving, add 5g CTAB, 10mL isopropanol and 15mL carbon tetrachloride respectively, stir well until completely dissolved to form a stable W / O type NaOH inverse microemulsion ; Then at a flow rate of 1 mL / min, the NaOH inverse microemulsion was added to Fe 2+ / Fe 3+ In the reversed-phase microemulsion, after all the additions are completed, continue to stir the reaction for 30 minutes until the reaction is complete...

Embodiment 3

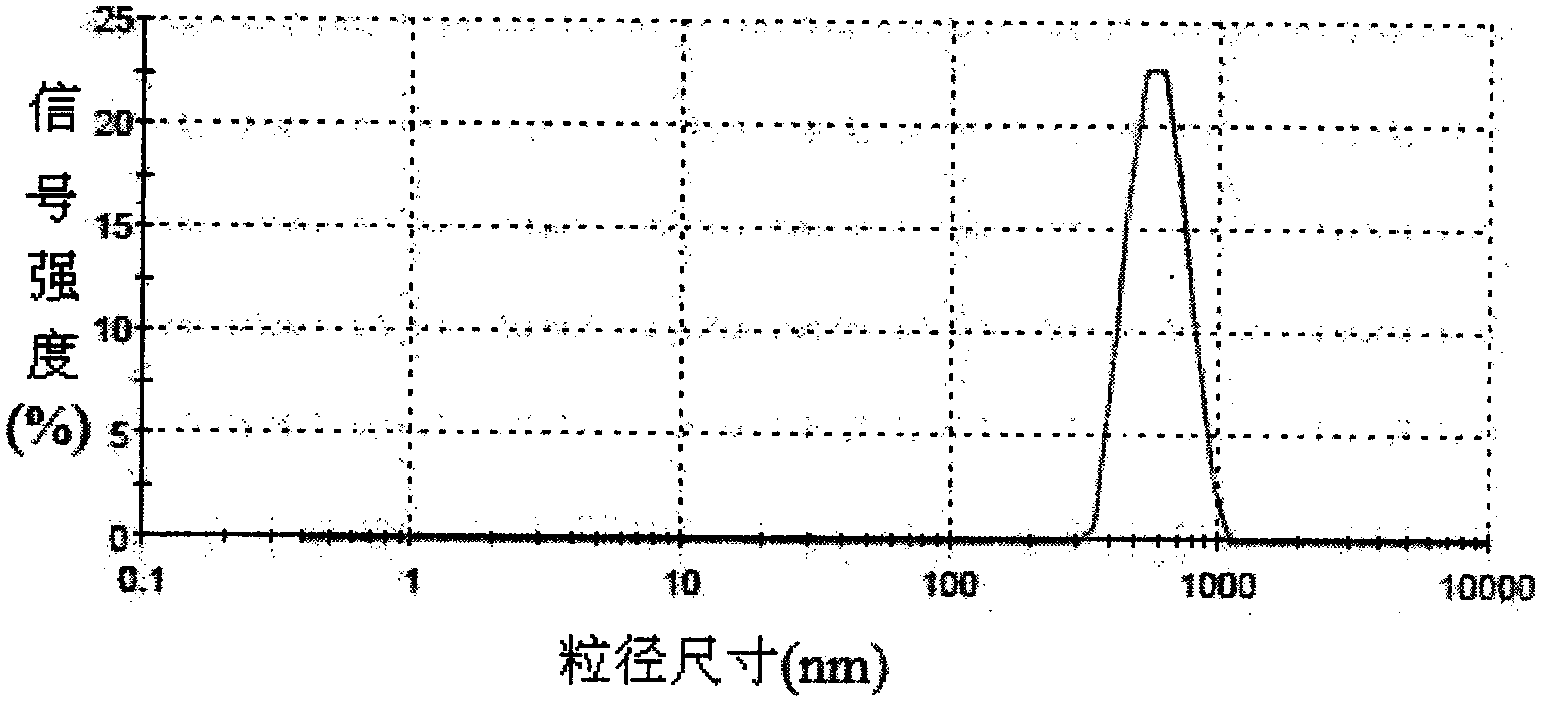

[0031] Take two conical flasks, add 10 mL of deionized water to one of the flasks, pass N 2 After removing the air in the triangular flask and the water, add 0.186g Fe (NO 3 ) 2 and 0.502gFe(NO 3 ) 3 , after completely dissolving, add 10g CTAB, 20mL isopropanol and 30mL n-heptane respectively, stir fully until completely dissolved to form stable W / O Fe 2+ / Fe 3+ Inverted microemulsion; add 5.0 mL of deionized water to a separate bottle, pass N 2 After removing the air in the conical flask and the water, add 0.448g KOH, after dissolving, add 5g CTAB, 10mL isopropanol and 15mL n-heptane respectively, stir well until completely dissolved to form a stable W / O type KOH inverse microemulsion; At a flow rate of 1 mL / min, KOH inverse microemulsion was added to Fe 2+ / Fe 3+ In the reversed-phase microemulsion, after all the additions are completed, continue to stir the reaction for 30 minutes until the reaction is complete; then add 5 mL of 2.0% (mass fraction) sodium alginate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com