Carbon fiber composite material recovery method

A composite material and recycling method technology, applied in the field of carbon fiber composite material recycling, can solve the problems of waste of land resources, incomplete cleaning, and pollution of the surrounding environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

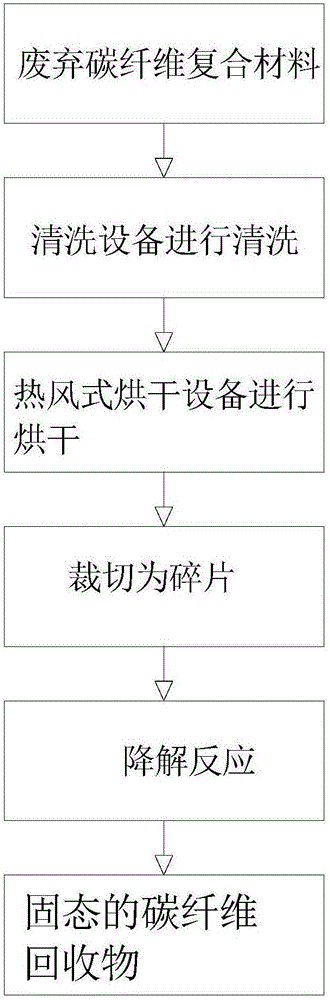

[0015] A carbon fiber composite material recycling method, comprising the following steps:

[0016] Step 1, put the waste carbon fiber composite material into the stirring and cleaning equipment for cleaning, and the cleaning temperature is 20 ℃,

[0017] In step 2, the cleaned carbon fiber composite material is dried by using a hot air drying device, and the carbon fiber composite material is pulverized into fragments with a length of 3 cm by a pulverizing device,

[0018] Step 3: Spread the fragments on a tray, place them in a microwave oven, and irradiate and heat the carbon fiber composite material fragments in the tray. The microwave power of the microwave oven is 3KW, and the microwave oven is filled with an inert gas. Degradation reaction occurs in the internal protection,

[0019] Step 4: After the degradation of the carbon fiber composite material is completed, a solid carbon fiber recycled material is obtained.

[0020] Among them, the degradation reaction time of ...

Embodiment 2

[0022] A carbon fiber composite material recycling method, comprising the following steps:

[0023] Step 1, put the waste carbon fiber composite material into the stirring and cleaning equipment for cleaning, and the cleaning temperature is 35 ° C,

[0024] In step 2, the cleaned carbon fiber composite material is dried by using a hot air drying device, and the carbon fiber composite material is pulverized into fragments with a length of 6 cm by a pulverizing device,

[0025] Step 3: Spread the fragments on the tray, place them in a microwave oven, and irradiate and heat the carbon fiber composite material fragments in the tray. The microwave power of the microwave oven is 6KW, and the microwave oven is filled with inert gas. Degradation reaction occurs in the internal protection,

[0026] Step 4: After the degradation of the carbon fiber composite material is completed, a solid carbon fiber recycled material is obtained.

[0027] Among them, the degradation reaction time of...

Embodiment 3

[0029] A carbon fiber composite material recycling method, comprising the following steps:

[0030] Step 1, put the waste carbon fiber composite material into the stirring and cleaning equipment for cleaning, and the cleaning temperature is 50 ℃,

[0031] In step 2, the cleaned carbon fiber composite material is dried by using a hot air drying device, and the carbon fiber composite material is pulverized into fragments with a length of 10 cm by a pulverizing device,

[0032] Step 3: Spread the fragments on a tray, place them in a microwave oven, and irradiate and heat the carbon fiber composite material fragments in the tray. The microwave power of the microwave oven is 10KW, and the microwave oven is filled with an inert gas. Degradation reaction occurs in the internal protection,

[0033] Step 4: After the degradation of the carbon fiber composite material is completed, a solid carbon fiber recycled material is obtained.

[0034] Among them, the degradation reaction time o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com