Automatic sorting, residue dumping and cleaning conveyor for tableware

An automatic sorting and conveyor technology, which is applied to conveyors, tableware washing machines/rinsing machines, mechanical conveyors, etc., can solve the problems of affecting the quality of dining in restaurants, wasting space, consuming manpower and time, and rubbing into throats, etc. , to achieve the effect of easy cleaning of equipment, flat and smooth conveying surface, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

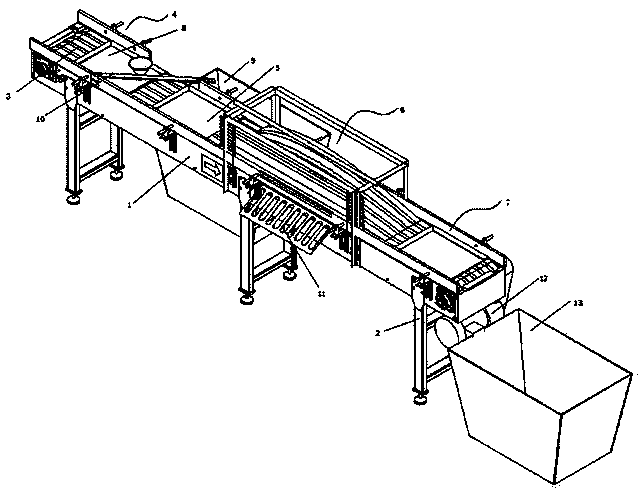

[0016] See figure 1 As shown, a tableware automatic sorting and slag cleaning conveyor has a fuselage 1 and machine feet 2 supporting the fuselage 1. A track 3 is horizontally placed on the table of the fuselage 1, and the track 3 is arranged from left to right in sequence. To the right there is a collecting assembly 4 for positioning and aligning the tableware, a washing assembly 5 for individually and continuously moving the tableware to washing, and a recovery assembly 7 for reclaiming the tableware after the tableware is cleaned.

[0017] The collection assembly 4 is provided with a square platform 8 and a collection channel 9 for the bowls, and a guide bar 10 is provided between the platform 8 and the collection channel 9 . The fuselage 1 is composed of a multi-section roof chain conveyor and a flat top chain conveyor. A filter plate 11 is located in the middle of the fuselage 1 . The motor 12 located at the bottom of the recovery assembly 7 is driven by the belt drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com