All-purpose escape system for subway locomotives

An escape system, a general-purpose technology, applied in the field of escape systems, can solve the problems of increased door thickness, reduced reliability, complex mechanism, etc., and achieve the effect of fast recovery, high reliability and simple recovery operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

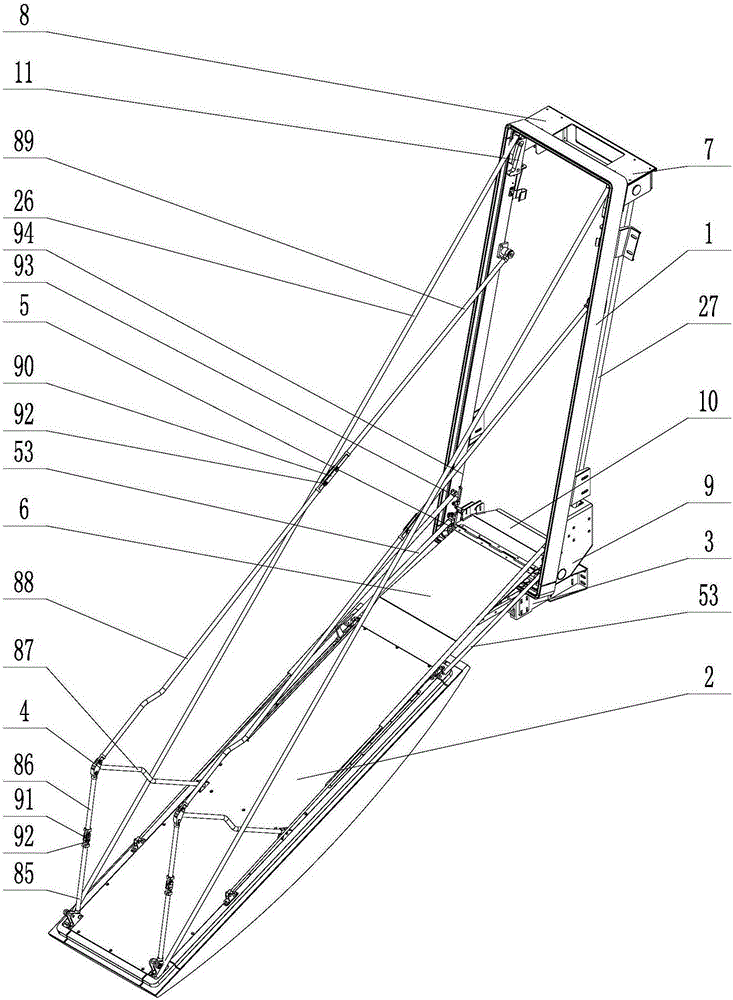

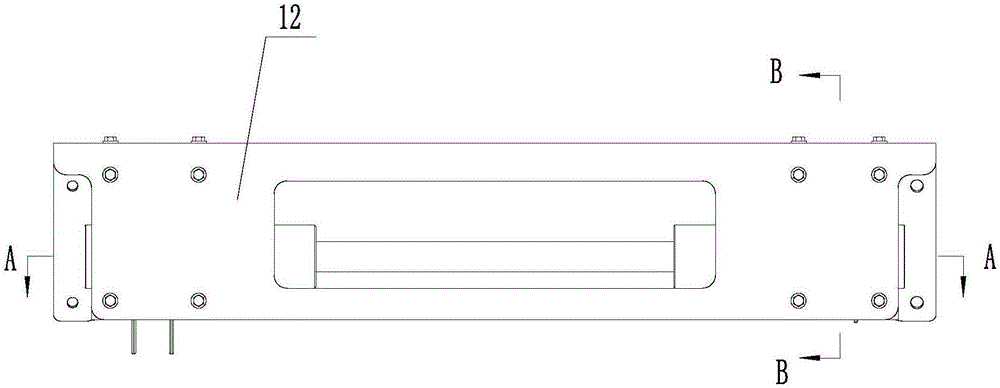

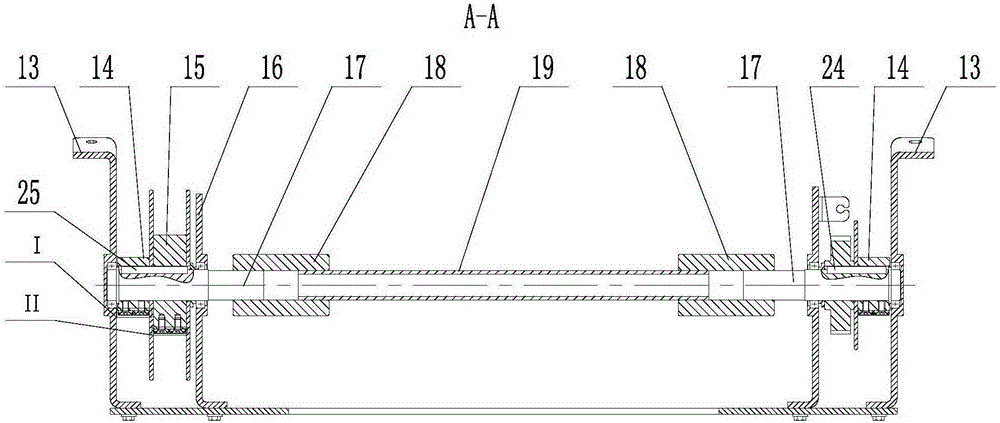

[0048] See figure 1 , Figure 17 , Figure 18 , Figure 20 , Figure 22 , Figure 23 with Figure 24 , a general-purpose escape system for subway locomotives of the present invention, the main structure of the escape system is made of aluminum alloy materials, mainly including a sealing frame 1, a door leaf 2, a push-out mechanism 3, a handrail rod 4, a lock mechanism 5, and a movable pedal 6 and the recovery mechanism 7; the sealing frame 1 is composed of welded aluminum profiles, the sealing frame 1 and the push-out mechanism 3 are fixed on the car body, the opening direction of the door leaf 2 is set to be forward, and the push-out mechanism 3 is located at the bottom of the seal frame 1 The bottom of the door leaf 2 is hinged on the front end of the guide rail transition plate 78 in the push-out mechanism 3, and the door leaf 2 adopts the structure of moving forward and turning over after being pushed out, and turning the door leaf 2 upwards, and the linkage cam 70 in...

Embodiment 2

[0062] A general-purpose escape system for subway locomotives of the present invention mainly includes a sealing frame 1, a door leaf 2, a push-out mechanism 3, a handrail rod 4, a lock mechanism 5 and a movable pedal 6; the sealing frame 1 is formed by welding aluminum profiles, and the sealing frame 1 and the push-out mechanism 3 are all fixed on the car body, the opening direction of the door leaf 2 is set to be forward, the push-out mechanism 3 can be a push-out rod, a wedge is arranged between the push-out mechanism 3 and the door leaf 2, and the lock mechanism 5 is integrated and installed On the inside top of the sealing frame 1, the push-out mechanism 3 is located in the middle of the seal frame 1, and the middle part of the door leaf 2 is hinged at the front end of the push-out mechanism 3; The top of the leaf 2 and the other end are hinged on the upper half of the sealing frame 1; one end of the movable pedal 6 is hinged in the door leaf 2 through a roller, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com