PVC (Polyvinyl Chloride) cable sheath material and preparation method thereof

A technology of cable sheath material and PVC resin, which is applied in the direction of insulating cables, cables, circuits, etc., to achieve the effects of wide practicability, reducing recycling costs, and saving recycling time

Pending Publication Date: 2014-05-07

苏州德亮材料科技有限公司

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the cable is recycled, its conductive layer and non-conductive layer need to be separated and recycled. The non-conductive layer of the cable is divided into an insulating layer and a sheath layer. It is not easy to separate the insulating layer and the sheath layer in existing cables.

For this reason, someone has invented processing equipment dedicated to wire and cable recycling. For example, the utility model patent with the authorized announcement number CN202363822U provides a waste cable stripping recycling processing equipment. However, this equipment focuses on cables of various shapes. The recycling of the wire is not specifically aimed at the separation of the insulating layer and the sheath layer that are not easy to peel off and recycled.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

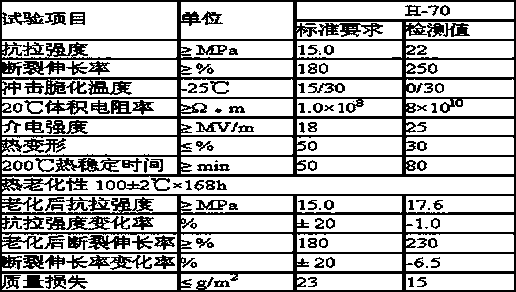

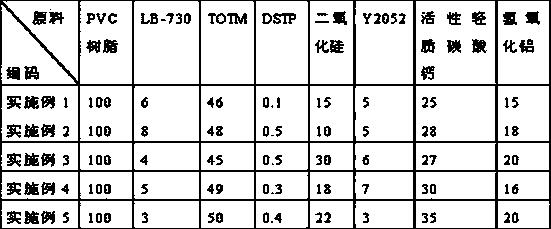

Embodiment 1-5

[0032] Prepare materials under items 1-5 according to Table 1, and operate according to the following methods:

[0033] In the kneader, add each raw material component, control the temperature, 70~110℃, stir evenly, send it to the extruder, control the temperature at 130~170℃, plasticize, extrude, and granulate to make an easy-to-peel PVC cable sheath Nested products.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of cable materials, and in particular relates to a PVC (Polyvinyl Chloride) cable sheath material which is mainly prepared from the following raw materials by weight: 100 parts of PVC resin, 3-8 parts of shock resistance modifying agent, 45-50 parts of plasticizer, 0.1-0.5 part of antioxidant, 10-30 parts of silicon dioxide, 3-7 parts of thermal stabilizing agent, 25-35 parts of filling agent and 15-20 parts of fire retardant. The PVC cable sheath material provided by the invention is excellent in mechanical physical property and meets the environment-friendly requirements, and meanwhile as silicon dioxide is added into the PVC cable sheath material, the surface of a sheath layer is rough, and the contact area of the sheath layer and an insulating layer can be easily separated as the contact area is reduced.

Description

technical field [0001] The invention belongs to the field of cable materials, and in particular relates to an easily peelable PVC cable sheath material with high recycling efficiency and a preparation method thereof. Background technique [0002] In modern society, wires and cables can be seen everywhere, such as wires and broadband access lines used in homes and hotels; power cables and overhead cables laid by power departments, etc. Wires and cables play a very important role in national economy and social activities. status. With the rapid development of the economy, the wire and cable industry has become the second largest industry in my country. With the increasing development of life, various power systems and electrical appliances are updated and eliminated, and a large number of waste cables will be produced every year. The main components of waste cables include copper, aluminum, plastic, rubber, etc., which have a very high recycling rate. value. If a large numb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L51/00C08K13/02C08K3/36C08K5/12C08K5/372C08K3/26C08K3/22H01B3/44H01B7/295B29C47/92B29C48/92

CPCB29C48/04B29C48/92B29C2948/92704B29C2948/92895

Inventor 吴宏图曹亮

Owner 苏州德亮材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com