Overflow shutoff valve for liquefied gas container

A technology of gas storage tanks and stop valves, which is applied in gas/liquid distribution and storage, lift valves, safety valves, etc. It can solve the problems of prolonged recovery time, deterioration of the safety and reliability of gas storage tanks, and increased manufacturing costs. Achieve the effect of shortening recovery time, shortening gas refill time and preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

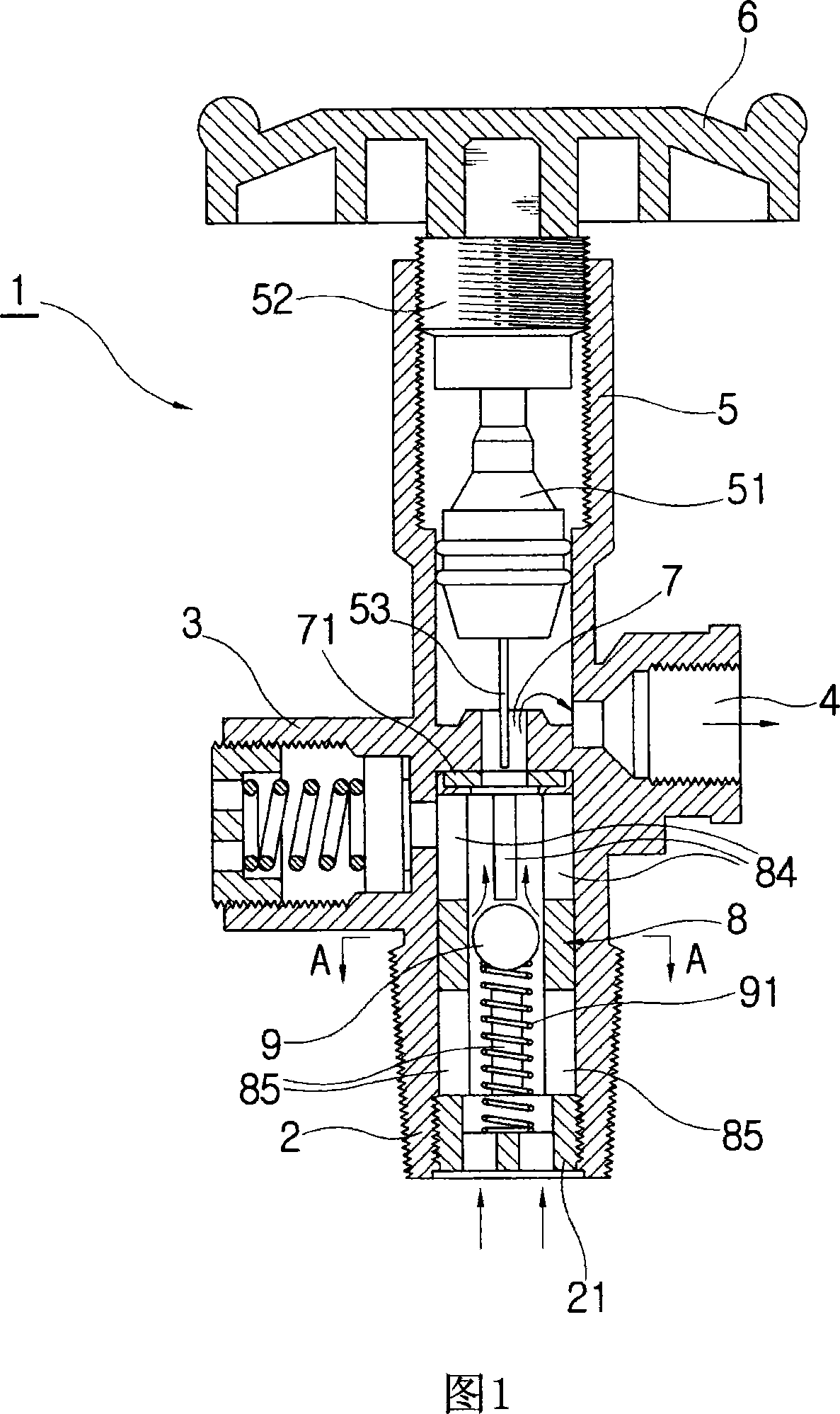

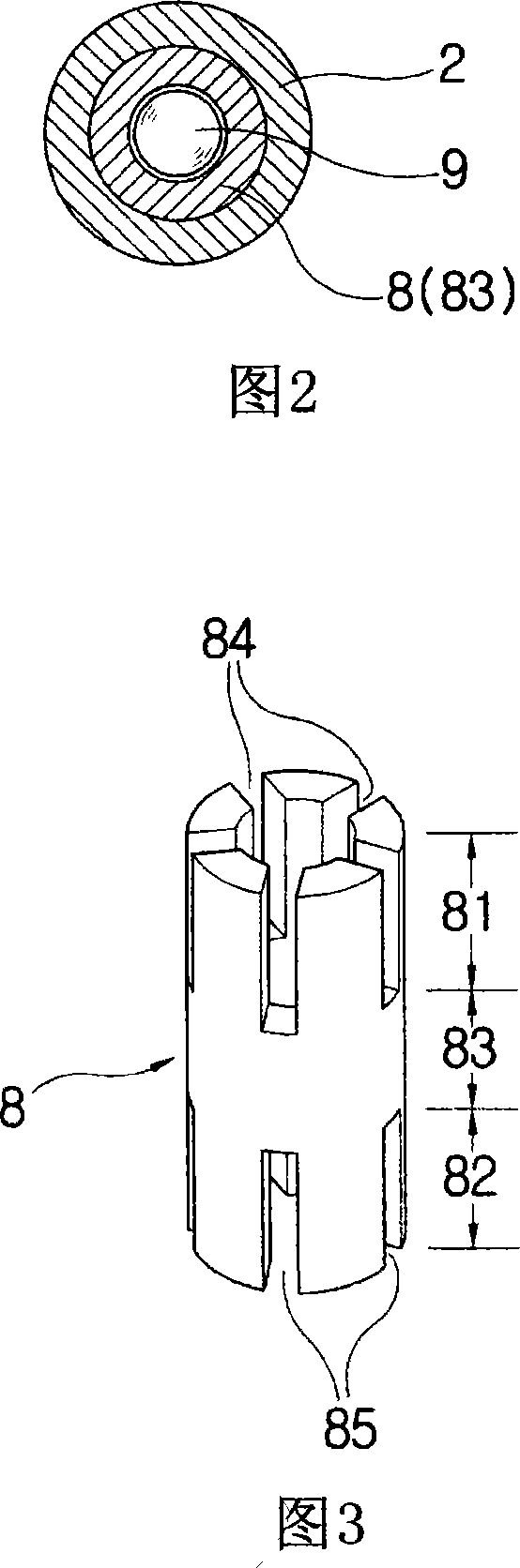

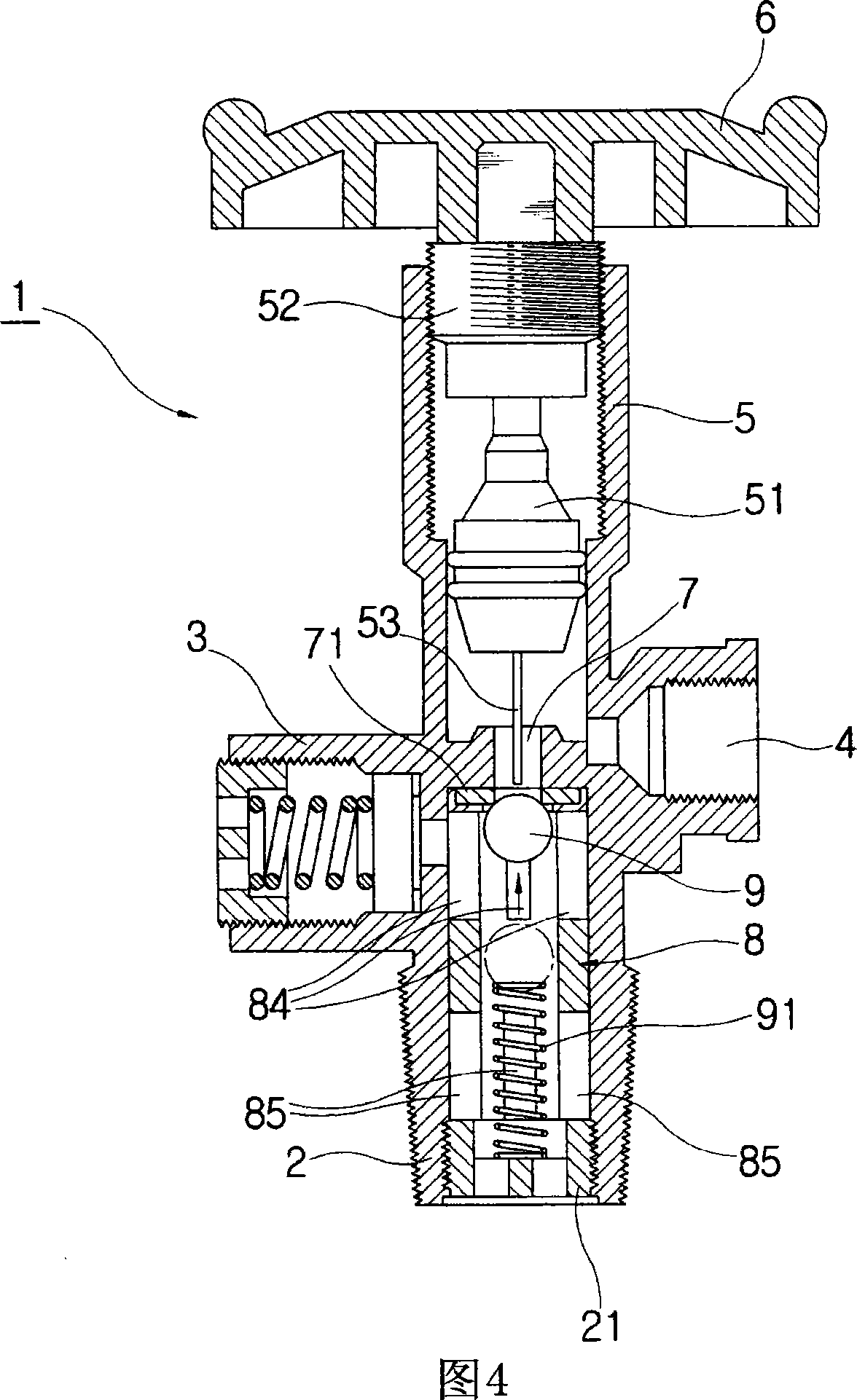

[0034] Fig. 1 is a sectional view showing the operation state of triggering the overflow stop valve when the gas is normally supplied, Fig. 2 is a sectional view along the line A-A of Fig. The perspective view of the cylinder above, Figure 4 is a cross-sectional view showing the state of triggering the overflow stop valve to interrupt the gas flow when the gas overflows, Figure 5 is a cross-sectional view showing the state of the overflow stop valve when the gas is recovered Operating state, FIG. 6 is a sectional view showing the operating state of the overflow stop valve when the gas tank is refilled with gas, and FIG. 7 is a sectional view along line B-B of FIG. 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com