Design method for property parameters of anti-collapse drilling fluid for fractured formations

A design method and drilling fluid technology, applied in the fields of calculation, electrical digital data processing, special data processing applications, etc., can solve the problem of not considering the influence of drilling fluid mechanical properties and stress distribution, not establishing the internal relationship of key performance parameters of drilling fluid, It is impossible to quantitatively reflect the application effect of drilling fluid and other problems, so as to achieve the effect of achieving wellbore stability and good wellbore stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0125] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

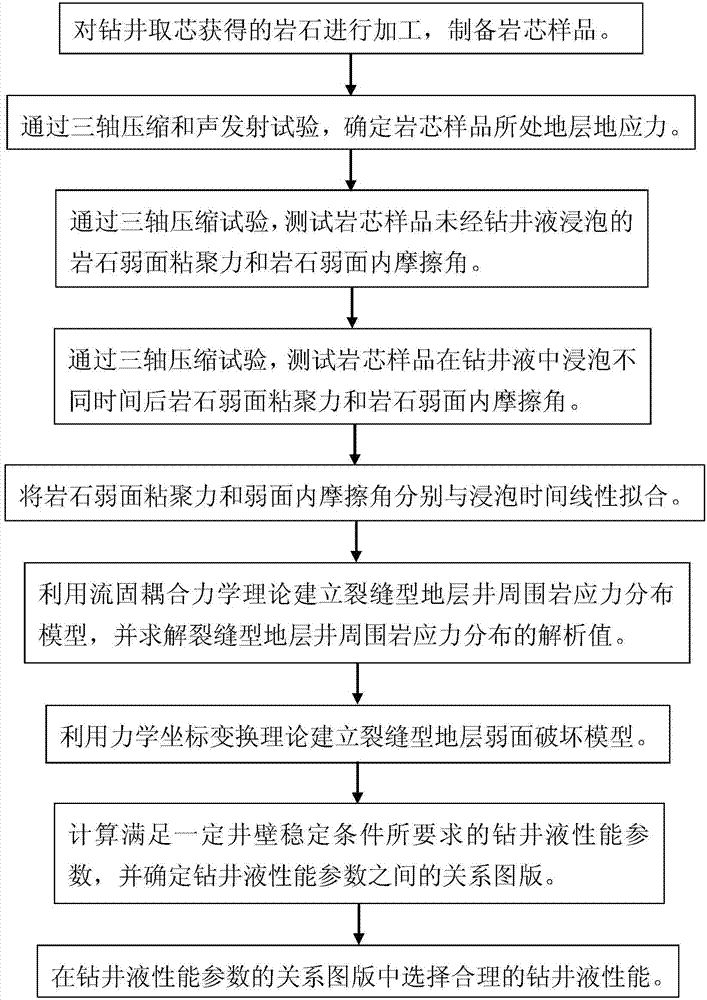

[0126] Such as figure 1 As shown, a method for designing performance parameters of anti-collapse drilling fluid in fractured formations, which includes the following steps in sequence:

[0127] Step 1: Process the rock obtained by drilling and coring to prepare core samples;

[0128] Step 2: Select a core sample, and perform a rock triaxial compression test and an acoustic emission test to determine the in-situ stress of the formation where the core sample is located;

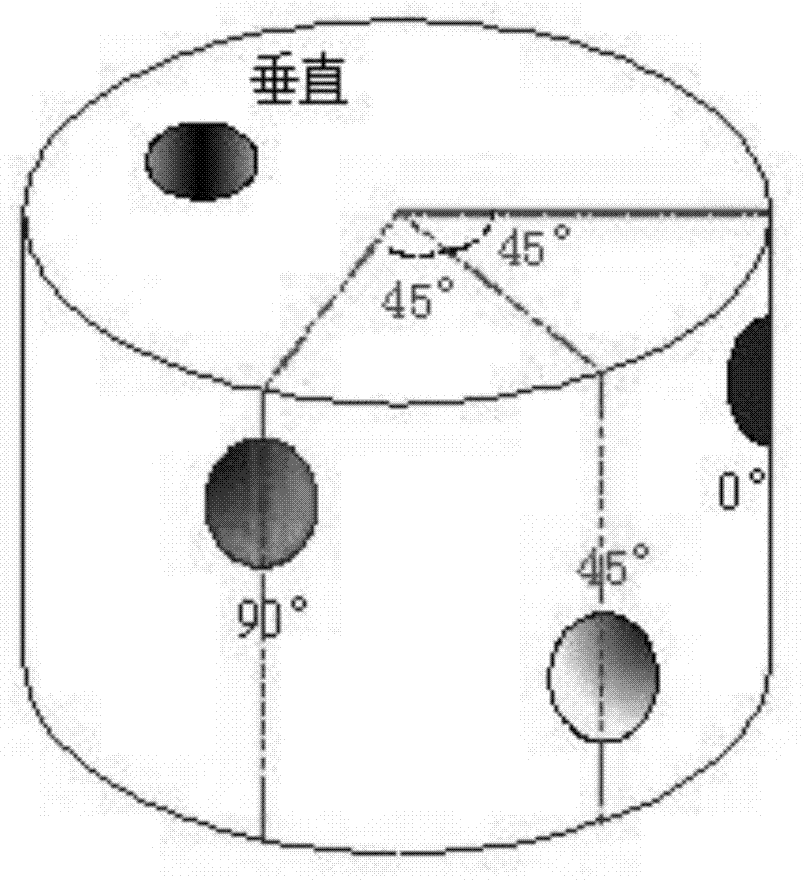

[0129] Step 3: Select the rock core sample and perform a rock triaxial compression test to test the cohesion of the rock weak surface and the internal friction angle of the rock weak surface of the core sample;

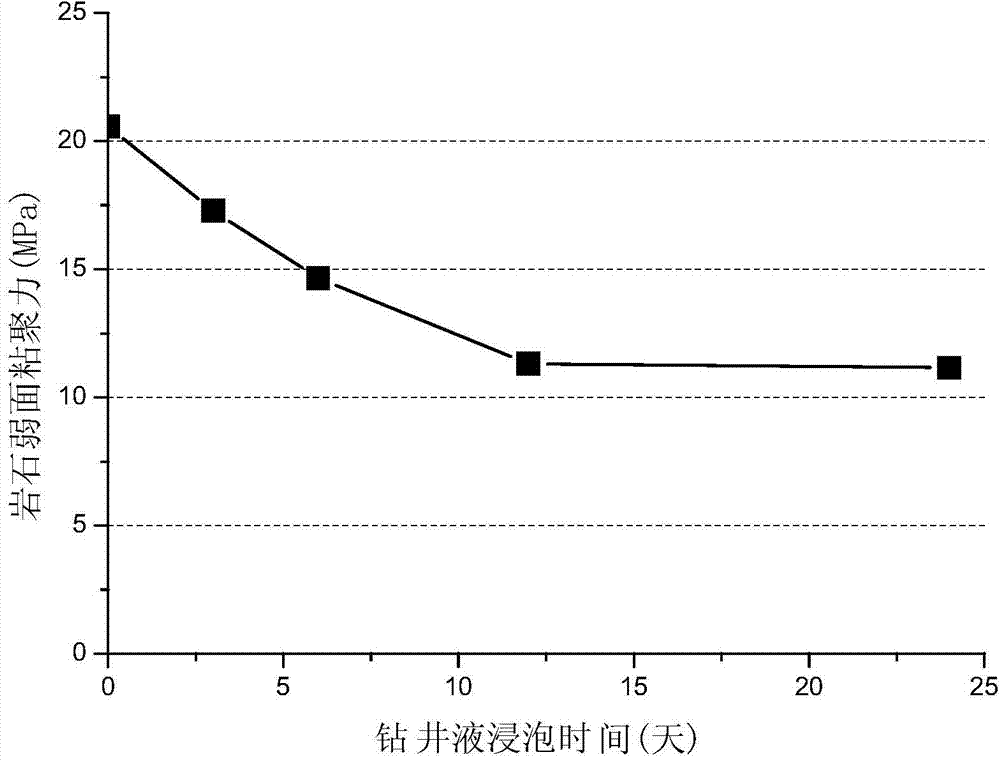

[0130] Step 4: Select the core samples, soak them in drilling fluid for different times, and conduct rock triaxial compression t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com