Liner hanger with sliding sleeve valve

a technology of sliding sleeve valve and liner hanger, which is applied in the direction of fluid removal, sealing/packing, and borehole/well accessories, etc., can solve the problems of increased drilling rig time, increased cost, and required equipment changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

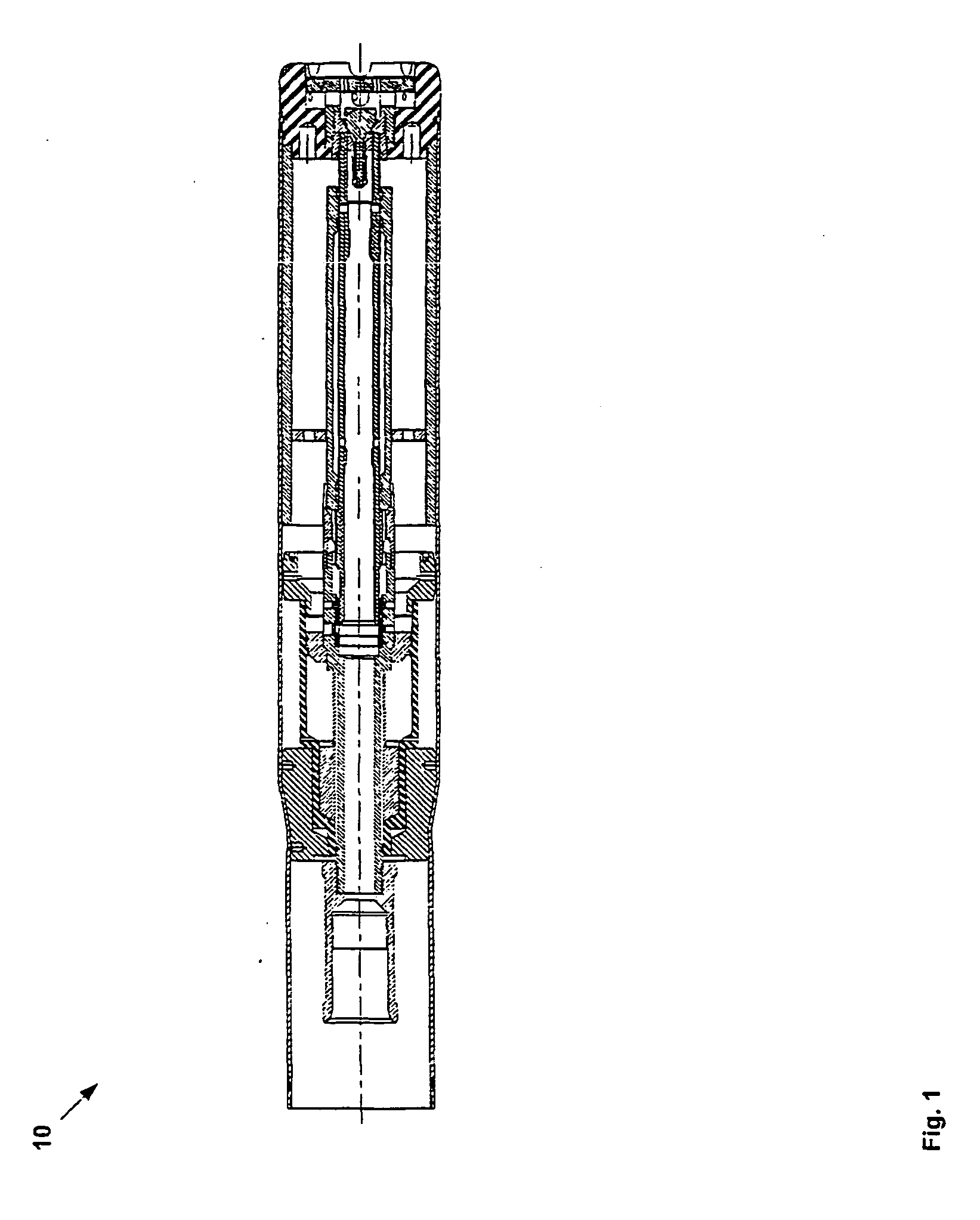

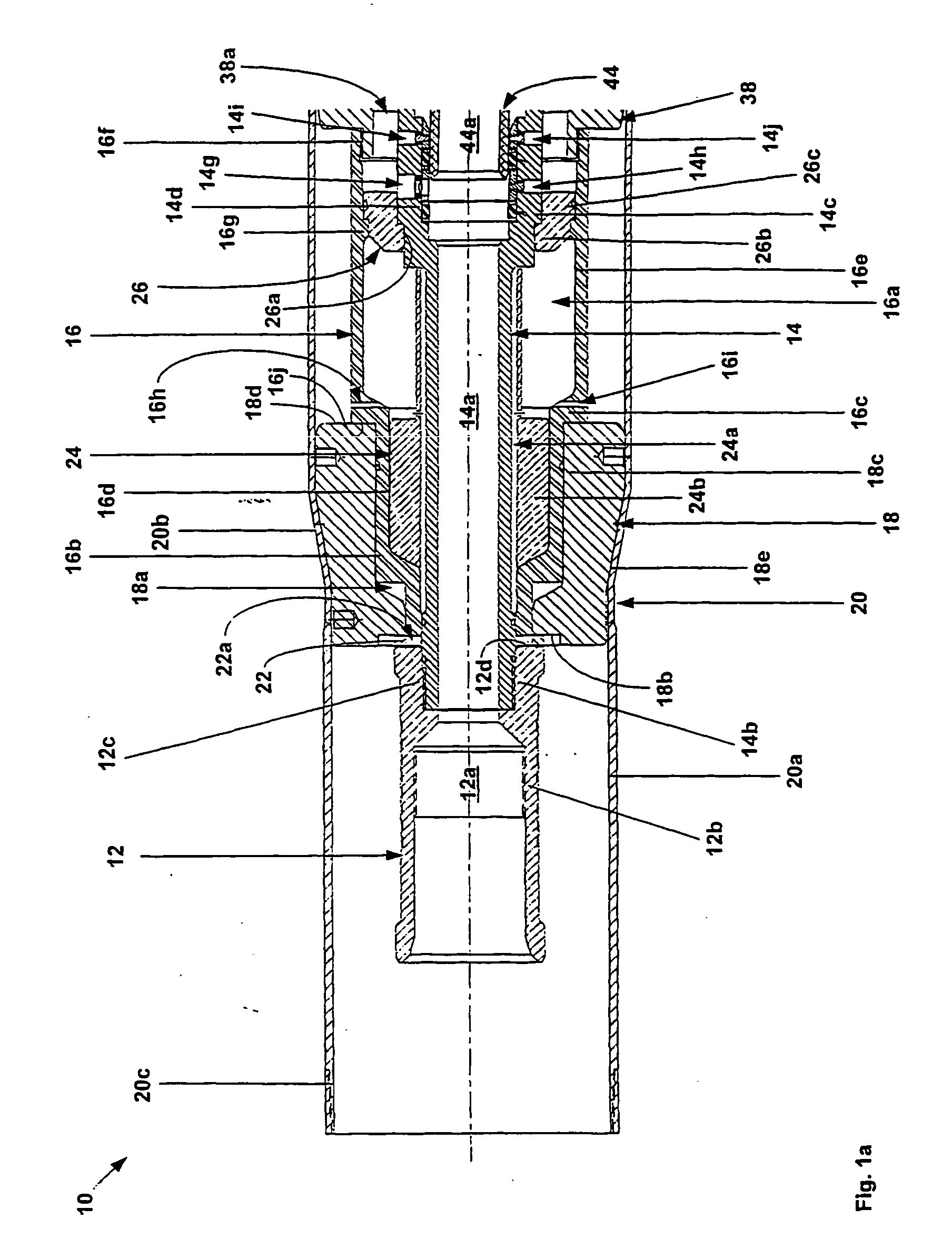

[0056] A liner hanger assembly having sliding sleeve bypass valve is provided. In several alternative embodiments, the liner hanger assembly provides a method and apparatus for forming or repairing a wellbore casing, a pipeline or a structural support.

[0057] Referring initially to FIGS. 1, 1a, 1b, and 1c, an embodiment of a liner hanger assembly 10 includes a first tubular support member 12 defining an internal passage 12a that includes a threaded counterbore 12b at one end, and a threaded counterbore 12c at another end. A second tubular support member 14 defining an internal passage 14a includes a first threaded portion 14b at a first end that is coupled to the threaded counterbore 12c of the first tubular support member 12, a stepped flange 14c, a counterbore 14d, a threaded portion 14e, and internal splines 14f at another end. The stepped flange 14c of the second tubular support member 14 further defines radial passages 14g, 14h, 14i, and 14d. A third tubular support member 16 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com