Tunnel ground deep-hole sleeve valve tube grouting construction method

A sleeve valve pipe grouting and construction method technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of radial grouting and curtain grouting that cannot meet the construction needs, safety problems, water leakage, etc. Achieve the effects of controlling the grouting range and depth, strengthening the soil, and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a grouting construction method for sleeve valve pipes with deep holes on the surface of tunnels, which is characterized in that: the grouting construction method for sleeve valve pipes with deep holes on the surface of tunnels is to process the tunnels that have been in operation, first The construction joints in the cave are treated with polyurethane waterproof material;

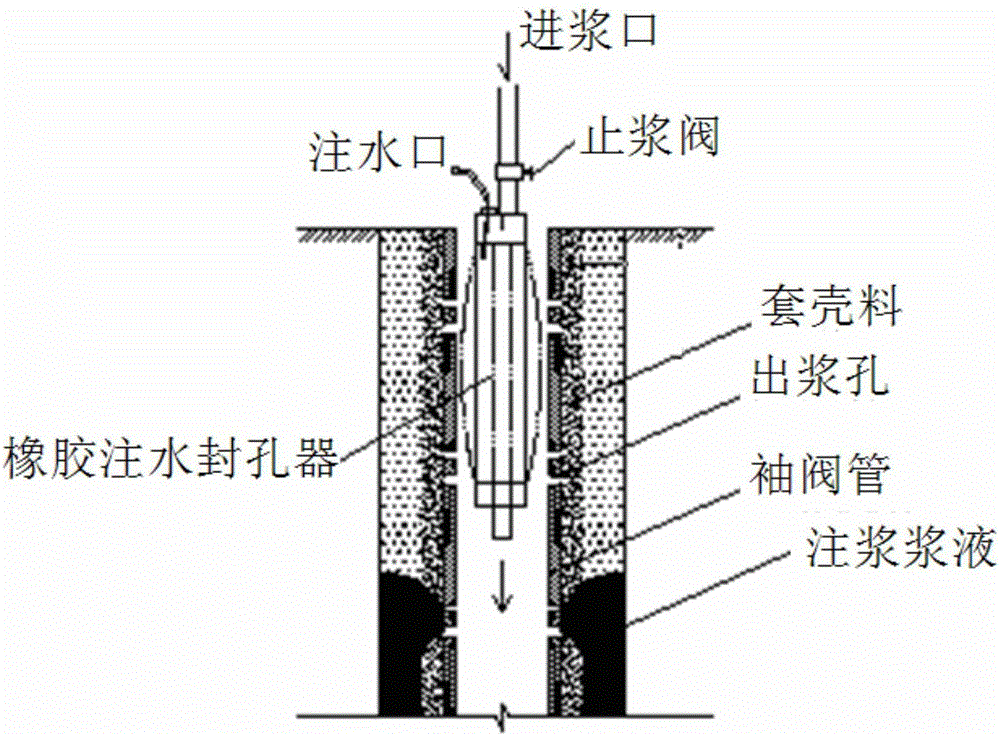

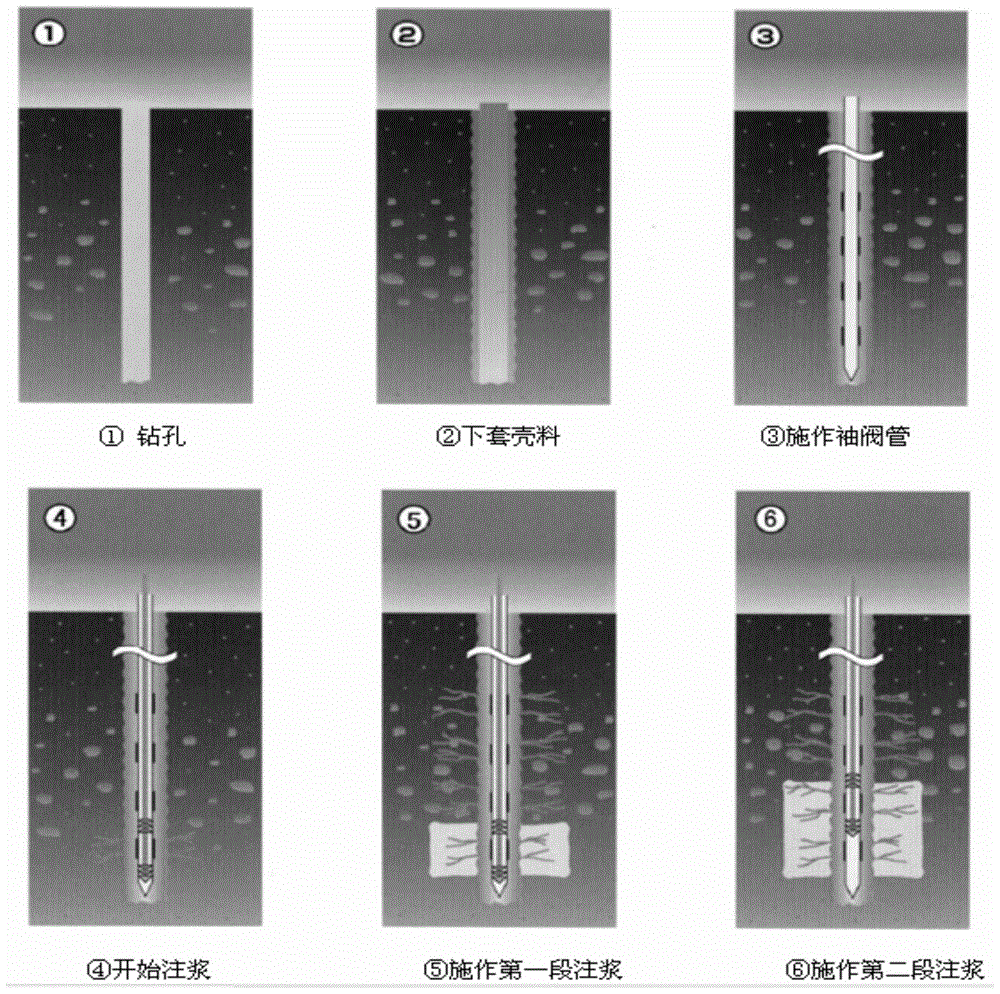

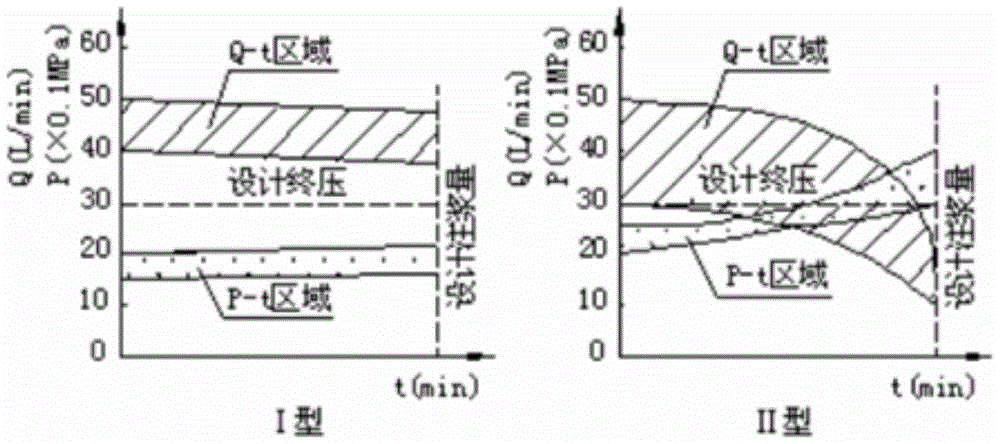

[0030] Then drill holes at a certain depth in the formation at a certain angle, place the sleeve valve pipe, pre-fill the shell material, the sleeve valve pipe will remain in the soil permanently, and reserve the slurry at a certain interval for the sleeve valve pipe hole, put the rubber water injection sealer in the sleeve valve tube, and add a stop valve at the grout inlet. Grouting method for grouting, and finally check the grouting effect, if the effect is not good, repeat grouting;

[0031] A pile with the borehole as the core is produced in the soil, and a tree root netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com