Construction method for grouting reinforcement of sleeve valve pipe

The technology of grouting and construction method of sleeve valve pipe is applied in basic structure engineering, soil protection, sheet pile wall and other directions, which can solve the problems of complicated construction process, easy occurrence of grouting and stuck pipe, and high price of grouting pipe. To achieve the effect of simple construction process, good application effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

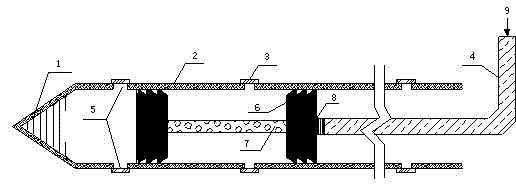

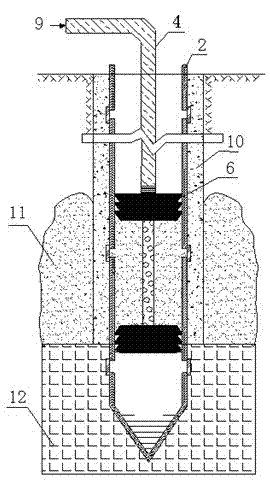

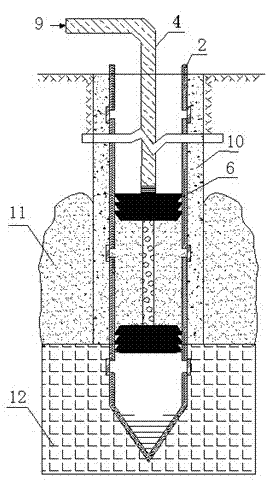

[0019] Embodiment of the present invention: it includes the following steps: first, drilling; second, inserting the grouting B pipe into the grouting drill hole; third, inserting the grouting A pipe into the grouting B pipe; fourth, sealing hole; fifth, grouting.

[0020] Insert the grouting B pipe into the grouting drill hole, the grouting B pipe will go down to the bottom of the hole, and the top will be higher than the ground.

[0021] In the step of inserting the grouting pipe A into the grouting pipe B, add a stepped grout stopper to the bottom of the connected grouting pipe A, and slowly insert it into the grouting pipe B section by section.

[0022] After the grouting A pipe is inserted into the bottom of the grouting B pipe, inject the sealing grout to fill the gap between the grouting B pipe and the soil; after the sealing grout is injected, fill the grouting pipe with water, and use gravity to Make the grouting pipe B not float, then lift out the A pipe slowly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com