Method of segmenting grouting by using grouting anchor cable

A technology of grouting anchor cables and segmental grouting, which is applied in the direction of earth drilling, installation of anchor rods, mining equipment, etc., can solve the problems such as inability to segmental grouting, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

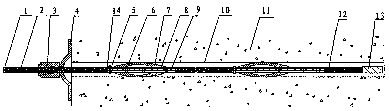

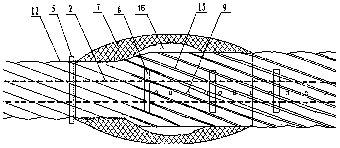

[0013] Such as figure 1 As shown, a method of segmented grouting using grouting anchor cables is as follows:

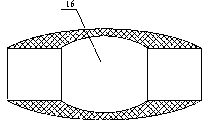

[0014] First arrange the grouting equipment in the roadway, drill the grouting anchor hole 10 in the roadway surrounding rock 11 according to the design, then put the hollow grouting anchor cable into the grouting anchor hole 10, and then connect the hollow grouting anchor cable The grouting equipment performs grouting in the hole to reinforce the cracks in the surrounding rock; wherein, the hollow grouting anchor cable is composed of a plurality of steel strands 12 spirally wound on the grouting core pipe 8 to form a cable body, and the top of the cable body is provided with The anchor head 13 is used to anchor the cable body at the bottom of the grouting anchor hole 10 with an anchoring agent through the anchor head 13; the grouting core tube 8 of the hollow grouting anchor cable is a soft plastic grouting tube, and the rear end of the cable body is welded with a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com