A prosthetic valve prosthesis with an anchor

A technology of artificial valves and fixing parts, which is applied in the field of medical devices, can solve the problems of reducing the service life of the valve, compression of the heart's own tissue, and poor leakage prevention effect, and achieve the effect of reducing the service life of the valve and enhancing the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

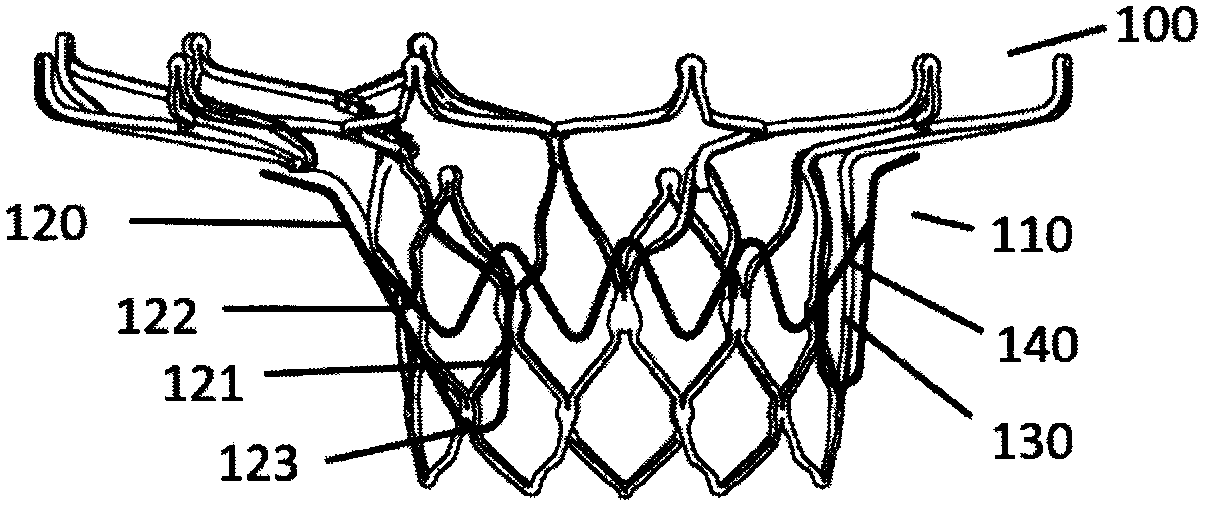

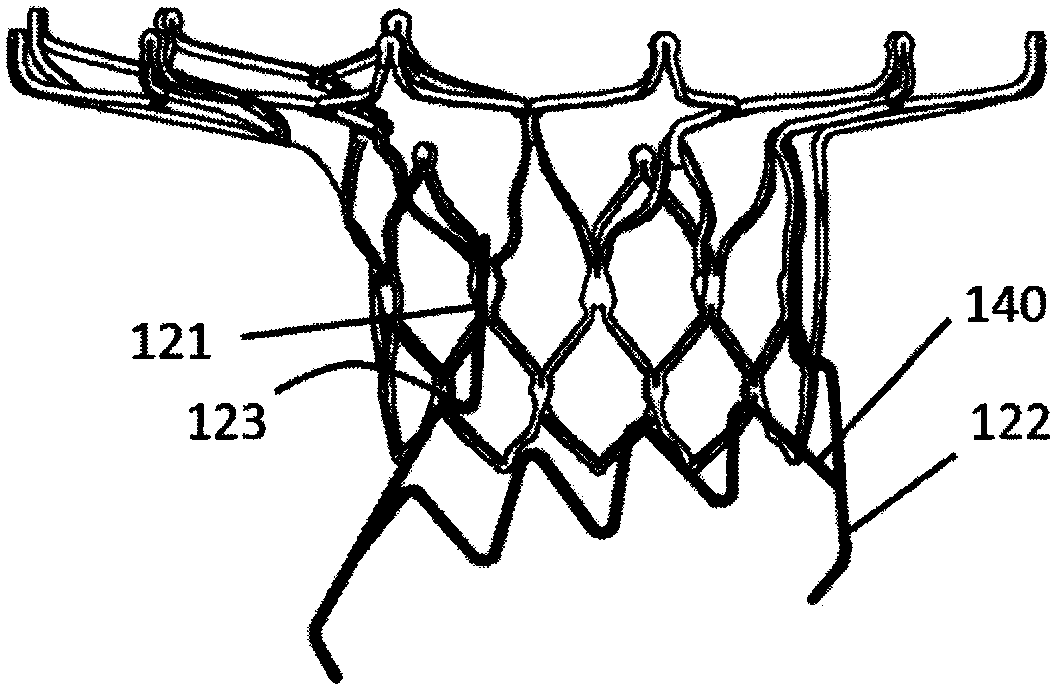

[0041] Such as Figure 1a and Figure 1b As shown, this embodiment introduces an artificial valve prosthesis 100 with a fixing part, which includes a stent body 110 having a channel for blood circulation and at least one fixing part 120, and the fixing part 120 is connected to the The bracket body 110, the fixing member 120 includes a lower extension section 121 and an upper extension section 122, one end of the lower extension section 122 is connected to the bracket body 110 as a fixed end, and the other end of the lower extension section 121 is along the The axis of the stent body 110 extends proximally, and after passing through the bending region 123, it extends distally in the opposite direction and connects with the upper extension section 122, which is located at the bottom of the lower extension section 121. On the outside, a valve leaflet accommodation cavity 130 is formed between the lower extension section 121 and the upper extension section 122, and the fixing memb...

specific Embodiment 2

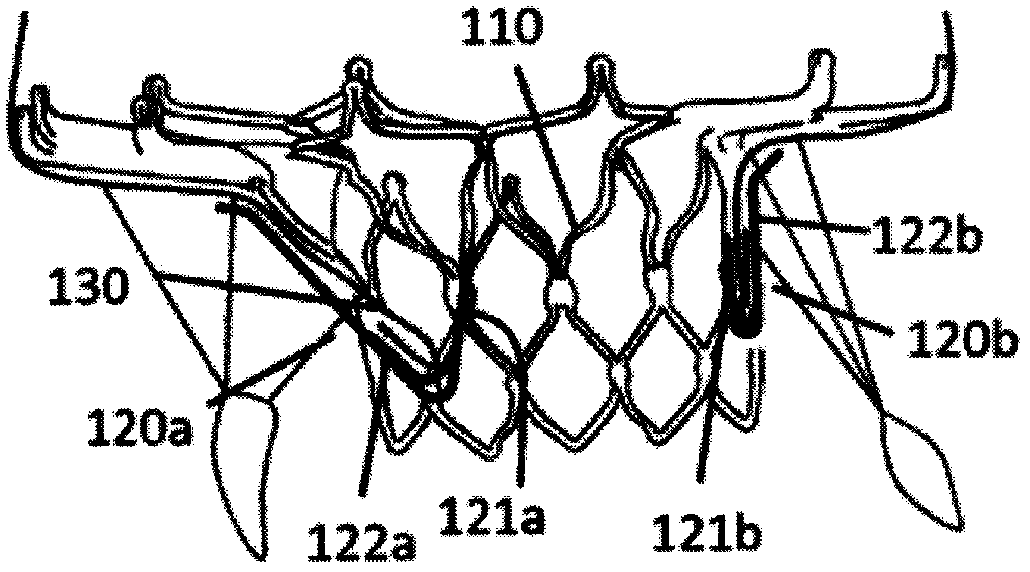

[0045] As another embodiment, such as Figure 3a and Figure 3b As shown, a prosthetic valve prosthesis 200 with a fixing part includes a stent body 210 having a channel for blood circulation and at least one fixing part 220, the fixing part 220 is connected to the stent body 210, the The fixing part 220 includes a lower extension section 221 and an upper extension section 222, one end of the lower extension section 222 is connected to the bracket body 210 as a fixed end, and the other end of the lower extension section 221 is along the axis of the bracket body 210 The direction of the heart line extends to the proximal end, and after passing through the bending area 223, it extends to the distal end in the opposite direction and is connected to the upper extension section 222, the upper extension section 222 is located outside the lower extension section 221, and the lower extension section 222 is located outside the lower extension section 221. The leaflet accommodation cav...

Embodiment approach

[0046] The stent body 210 further includes a valve sewing section 211 and an atrial positioning section 212 , the distal end of the valve sewing section 211 is connected to the proximal end of the atrial positioning section 212 . Different from the fixing part extending from the valve sewing section in the prior art, as an embodiment of the present invention, the lower extension section 221 is connected to the atrial positioning section 212 of the stent body 210, the The fixing part 220 is independent of the valve sewing section 211, which has the advantage of avoiding the contraction of the valve sewing section driven by the force of the valve from affecting the effect of clamping the leaflets, while allowing the valve sewing section of the present invention to be compared with the existing The size of the valve sewing section in the technology is small, which reduces the impact on the left ventricular outflow tract, which is conducive to sheath retraction and the selection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com