Exhaust manifold gas detection machine and detection method thereof

A technology of exhaust manifold and detection method, which is applied in the direction of measuring the increase and decrease rate of fluid, and liquid tightness measurement by using liquid/vacuum degree, which can solve the problem of poor detection effect, unstable clamping and unsatisfactory detection effect and other issues to achieve the effects of low production cost, increased quality and service life, and easy application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

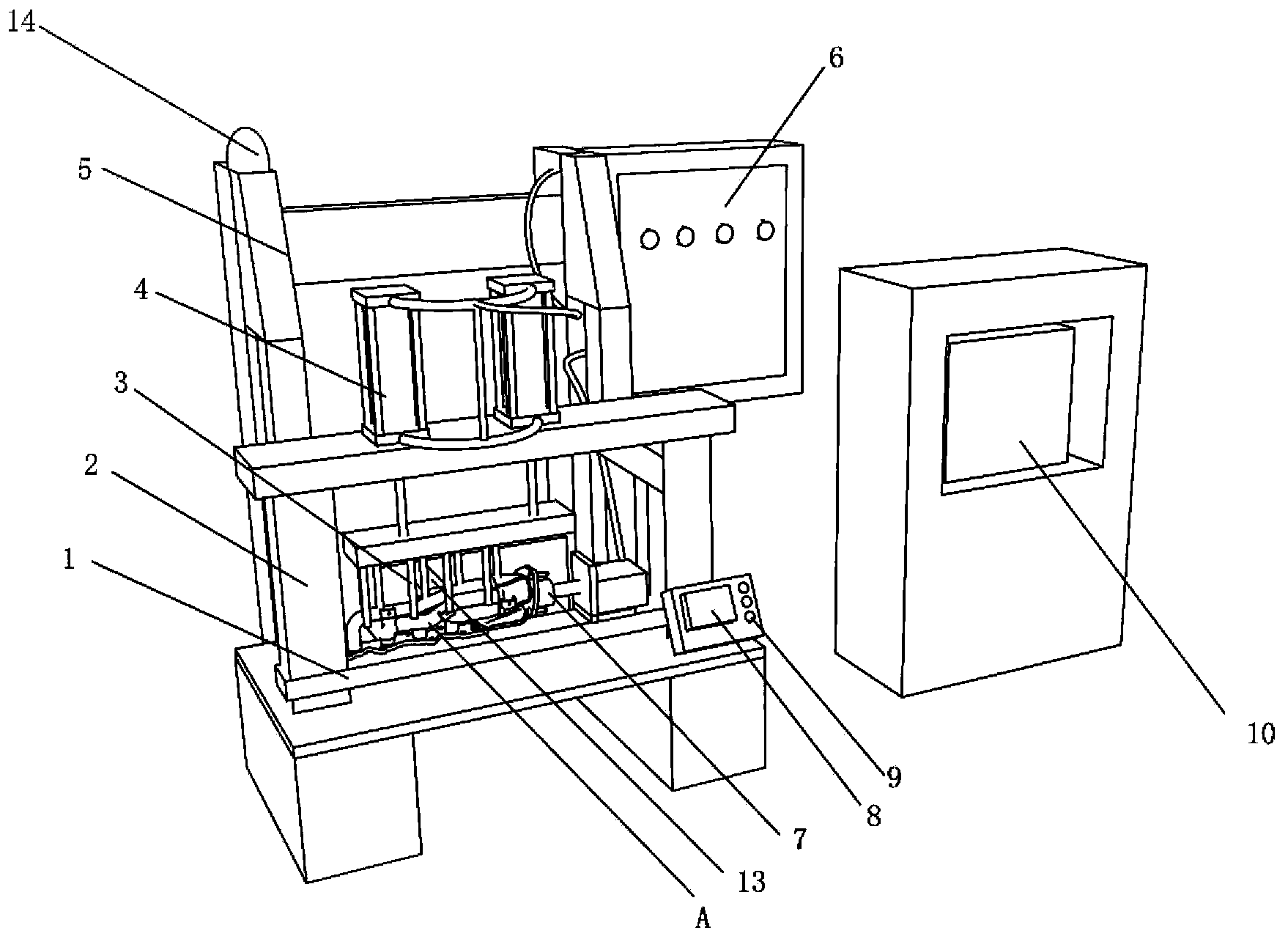

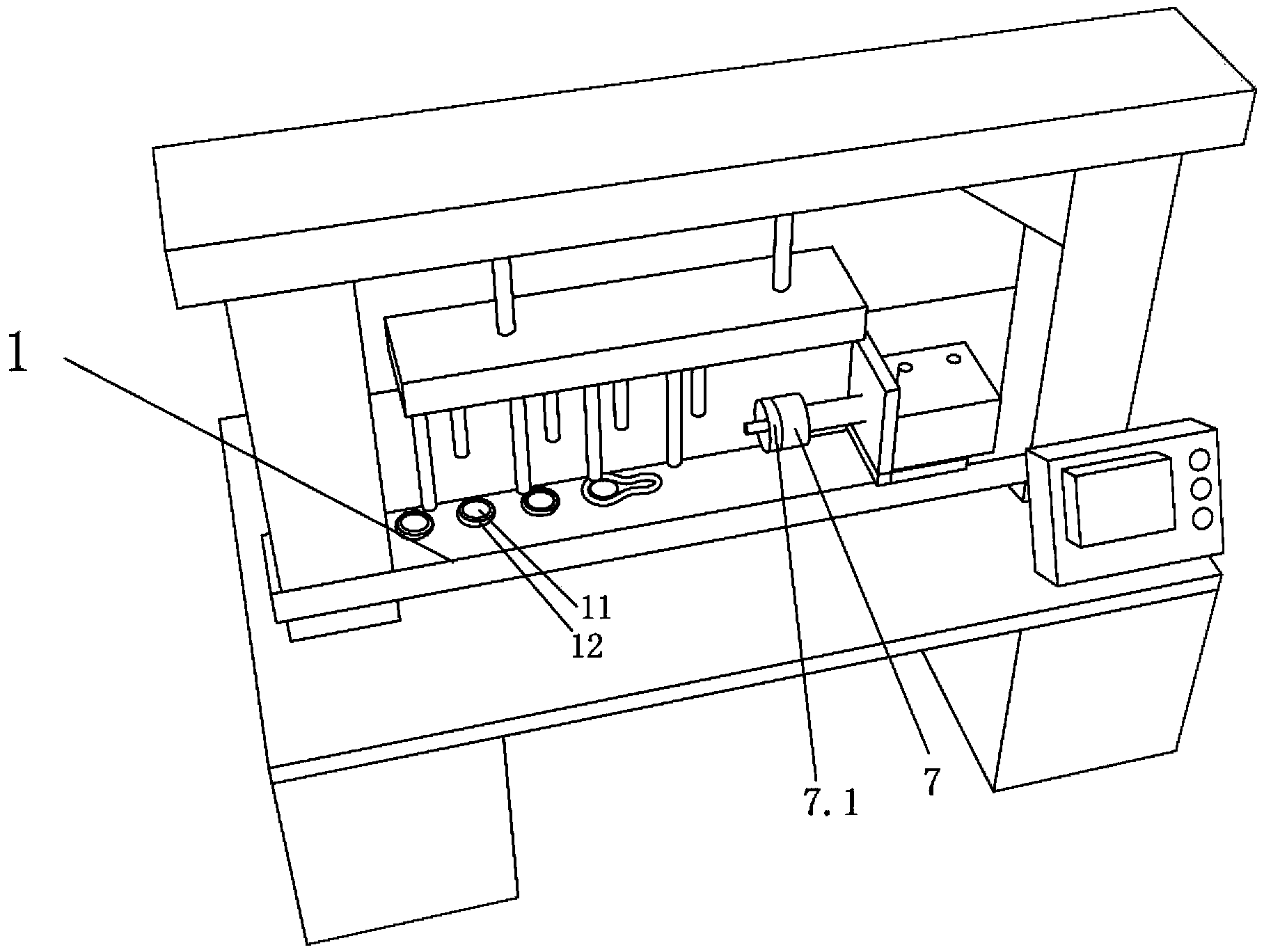

[0034] like figure 1 As shown, the gas detection machine for exhaust manifold of the present invention includes a detection platform 1 for placing the exhaust manifold. The detection platform is provided with a pressing device for pressing the exhaust manifold A, and the pressing device includes Lifting rod, the lifting rod is controlled by the cylinder block 4 to move up and down, and the lower part of the lifting rod is also equipped with a plurality of pressure rods 3 for pressing the exhaust manifold. The upper position is provided with an inflatable valve 7 that can slide in the detection platform 1, and the inflatable valve 7 controls its intake air volume and time through a control computer 10 and a control display panel. The control display panel includes a display screen 8 and a control key 9. In the display screen, There are pressure detection display parts, pressure drop range display parts, and ventilation time detection parts. The above-mentioned display parts can...

Embodiment 2

[0044] The difference from Embodiment 1 is that in this embodiment, the inflation time of the inflation valve 7 is set to 10S, the pre-variable pressure of the elastic seal 7.1 in the inflation valve 7 is 12N, and the preset inflation pressure value is 215 KPa. If the change value of the exhaust pipe pressure is less than 1.50 KPa, if it is greater than 1.50 KPa, an alarm will be displayed.

[0045] The rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com