Highly secure lithium ion dynamic battery and its assembly method

A lithium battery and power technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve problems such as user safety hazards, exothermic reaction explosion, etc., to reduce the risk of explosion, reduce the chance of external impact, The effect of reducing the heat release of thermal reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

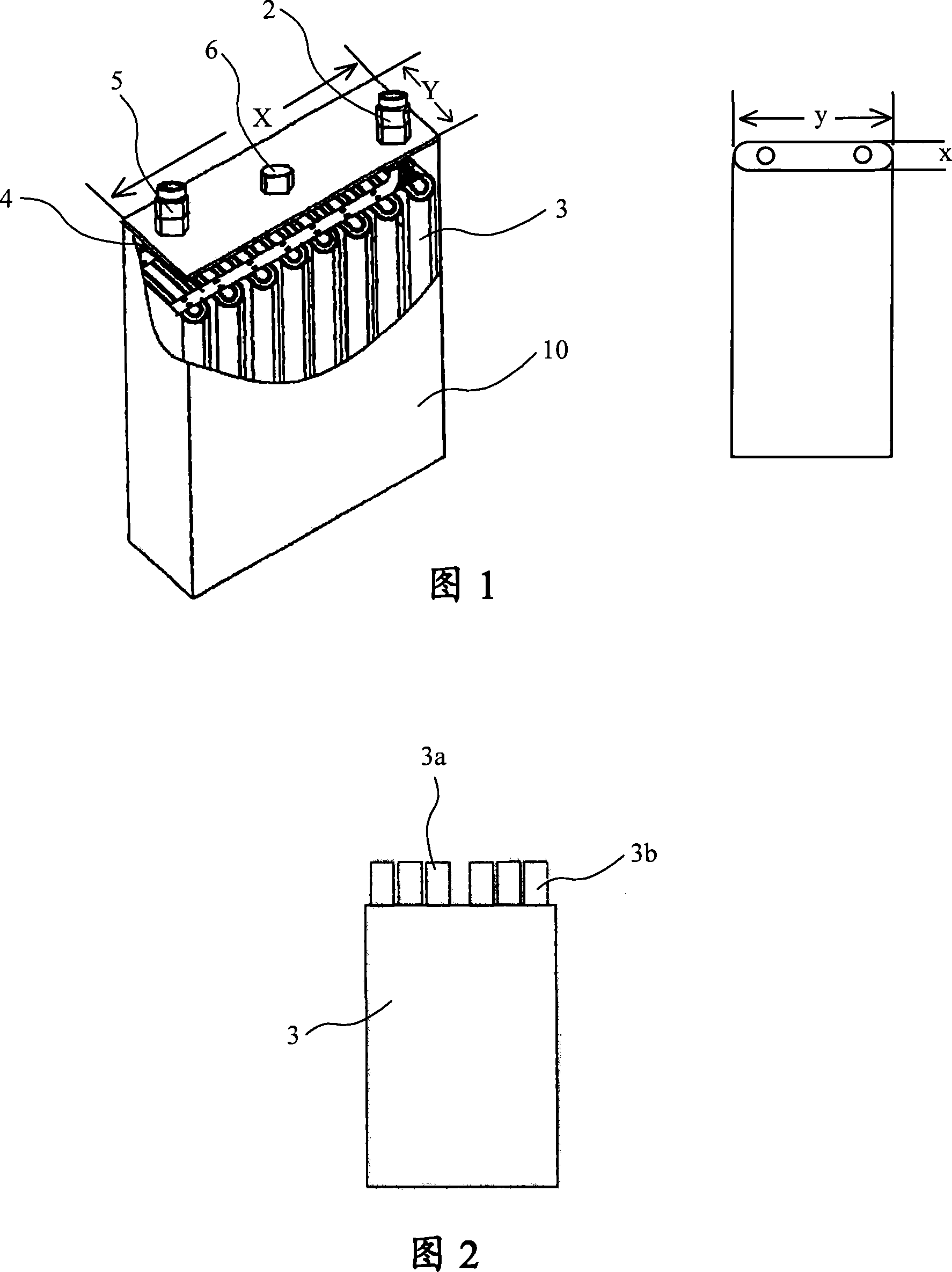

[0043] Example 1 Production of 50Ah high-power lithium-ion power battery

[0044] The cathode material is LiMn 2 o 4 , The battery is made by winding. After drying, 0.7M LiBOB electrolyte solution is vacuum-injected, and the solvent contains nonafluorobutyl ether (5-15% v / v). Each cell has a capacity of 10Ah.

[0045] Lead out the positive and negative tabs of each unit battery in parallel.

[0046] After forming the unit cell, assemble it in a rectangular parallelepiped casing, and then inject 50-150ml of a mixture of nonafluorobutyl ether and tributyl phosphate (the ratio is 1:2 (v / v)).

[0047] The unit cells are packaged and assembled into a whole battery.

Embodiment 2

[0048] Example 2: Fabrication of a 100Ah high-power lithium-ion power battery.

[0049] The cathode material is LiFePO 4 , The battery is laminated. After drying, the electrolyte is vacuum injected. LiBOB salt is used as the electrolyte, and carbonates are used as the solvent. The solvent contains tris(3-fluoroethyl phosphate), and its consumption is 10-20% (v / v) of the total solvent. The concentration of the conductive salt is 0.7M, and the capacity of the single battery is 10Ah.

[0050] Other preparation steps are identical with embodiment 1. The flame retardant is a mixture of tris(3-fluoroethyl phosphate) and nonafluorobutyl ether with a volume ratio of 1:2, and the dosage is 100-250ml.

Embodiment 3

[0051] Example 3: Fabrication of a 100Ah high-power lithium-ion power battery.

[0052] The cathode material is LiMn 2 o 4 The ratio of its dosage to LiNi1 / 3CO1 / 3Mn1 / 3O2 mixture is 3:7~4:6 (w / w). The production method is the same as Example 1. The electrolyte uses 0.4M LiPF6+0.7M LiBOB mixed salt as the electrolyte. The solvent system contains trifluoroethyl borate and nonafluorobutyl ether flame retardant in a ratio of 3:2 (v / v). The flame retardant accounts for 10-15% (v / v) of the total solvent. In order to reduce LiMn 2 o 4 Dissolve and add a small amount of polymer monomer (0.1-0.5%, w / v) to form a protective film on the positive electrode.

[0053] Other steps are identical with embodiment 1.

[0054] The flame retardant is a gel-type mixture of triphenyl phosphate and nonafluorobutyl ethyl ether, the volume ratio of which is 2:1-3:2 (v / v). The mixture is first loaded and heated to 46-55°C, then a certain amount of PVDF-HFP powder is added to dissolve it, and inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com