Additive for battery, cathode material containing same and preparation method for cathode material

A technology of positive electrode materials and additives, applied in the direction of electrode manufacturing, battery electrodes, electrolyte layer coatings, etc., can solve problems such as reducing sulfur utilization rate, specific capacity and cycle performance, increasing electrolyte viscosity and ion migration resistance, etc., to achieve reduction Effects of adverse effects, inhibition of dissolution, and reduction of loss of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

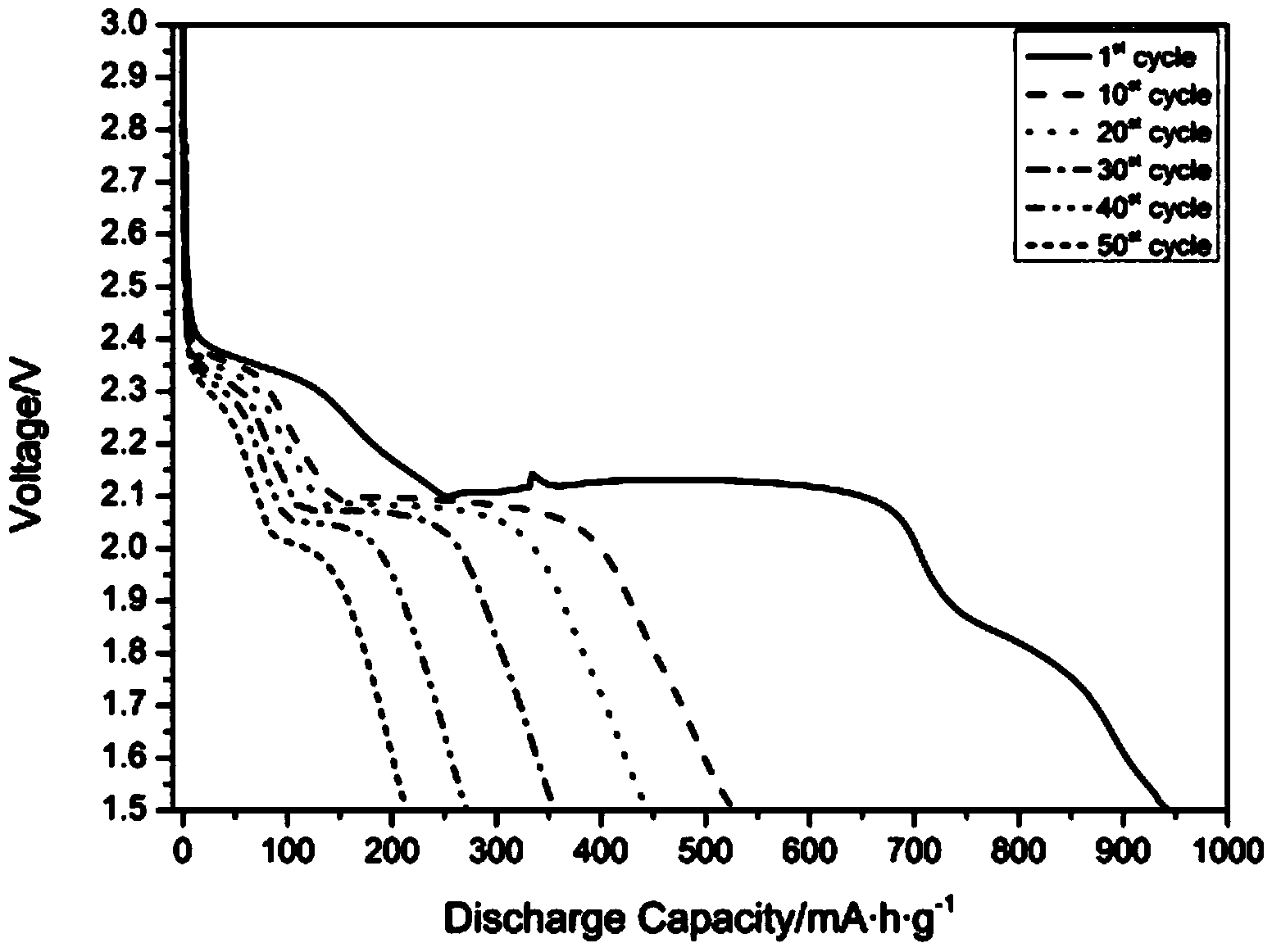

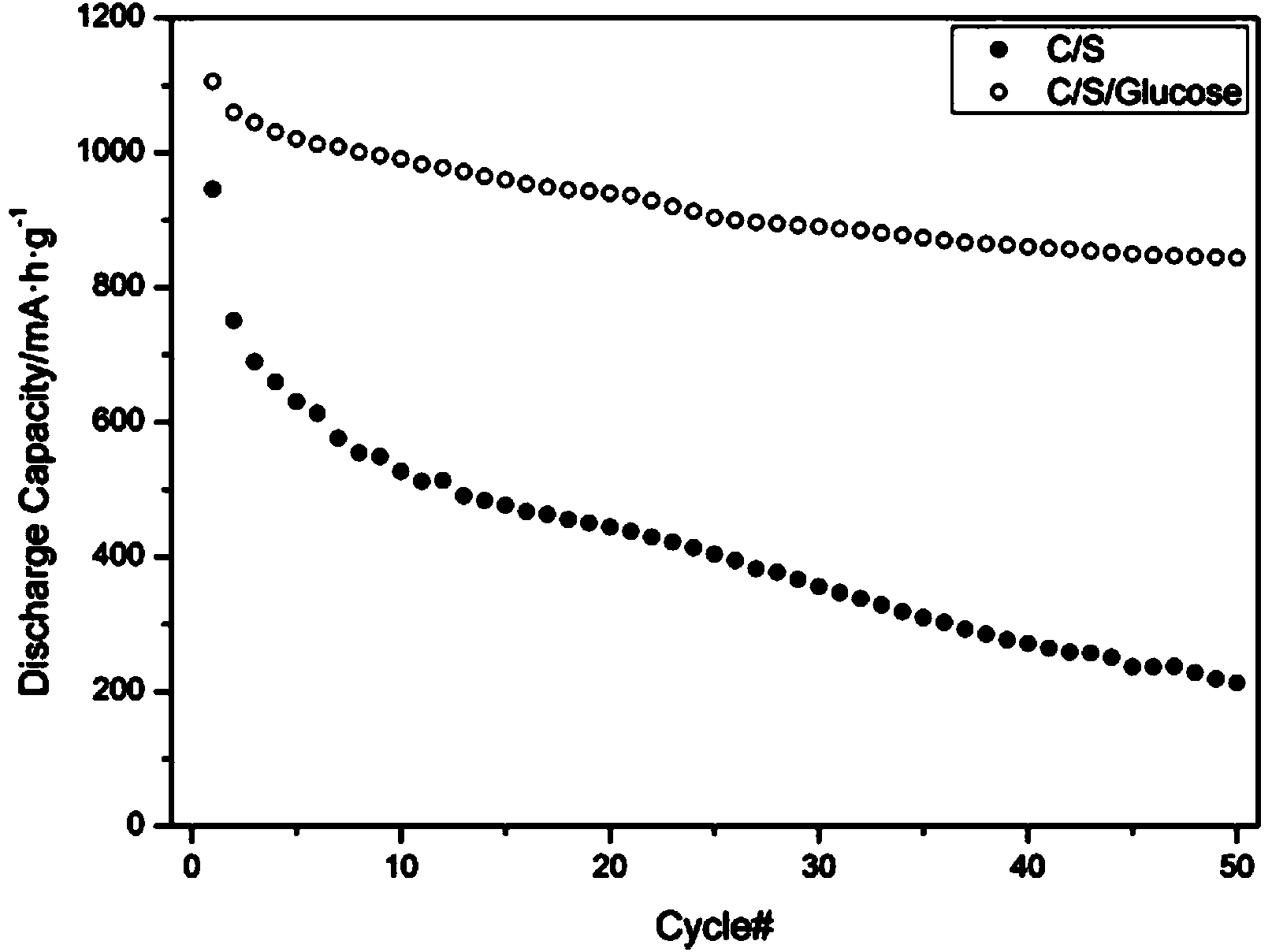

[0031] The additive provided in this example is a composite material of glucose (Glucose) and Super P, and the preparation method is as follows: take 1 g of Super P and 5 g of glucose and disperse them in 80 ml of deionized water, ultrasonically disperse them in an ultrasonic cleaner for 10 min, and transfer them to 100 mL In a hydrothermal reactor, react at 160°C for 48h. After the reaction is finished, filter with suction, dry at 65°C, and grind to obtain a composite material of glucose and Super P, that is, an additive, and then add the additive to the C / S system. The composite method is the same as in the comparative example, that is, the C / S S / Glucose composite cathode material, C: 58wt%, S: 40.00wt%, additive: 2.00wt% in the cathode material. The methods of preparing the positive electrode sheet, assembling the battery and testing the battery are the same as those in the comparative example. The battery charge and discharge test results show that the first charge and di...

Embodiment 2

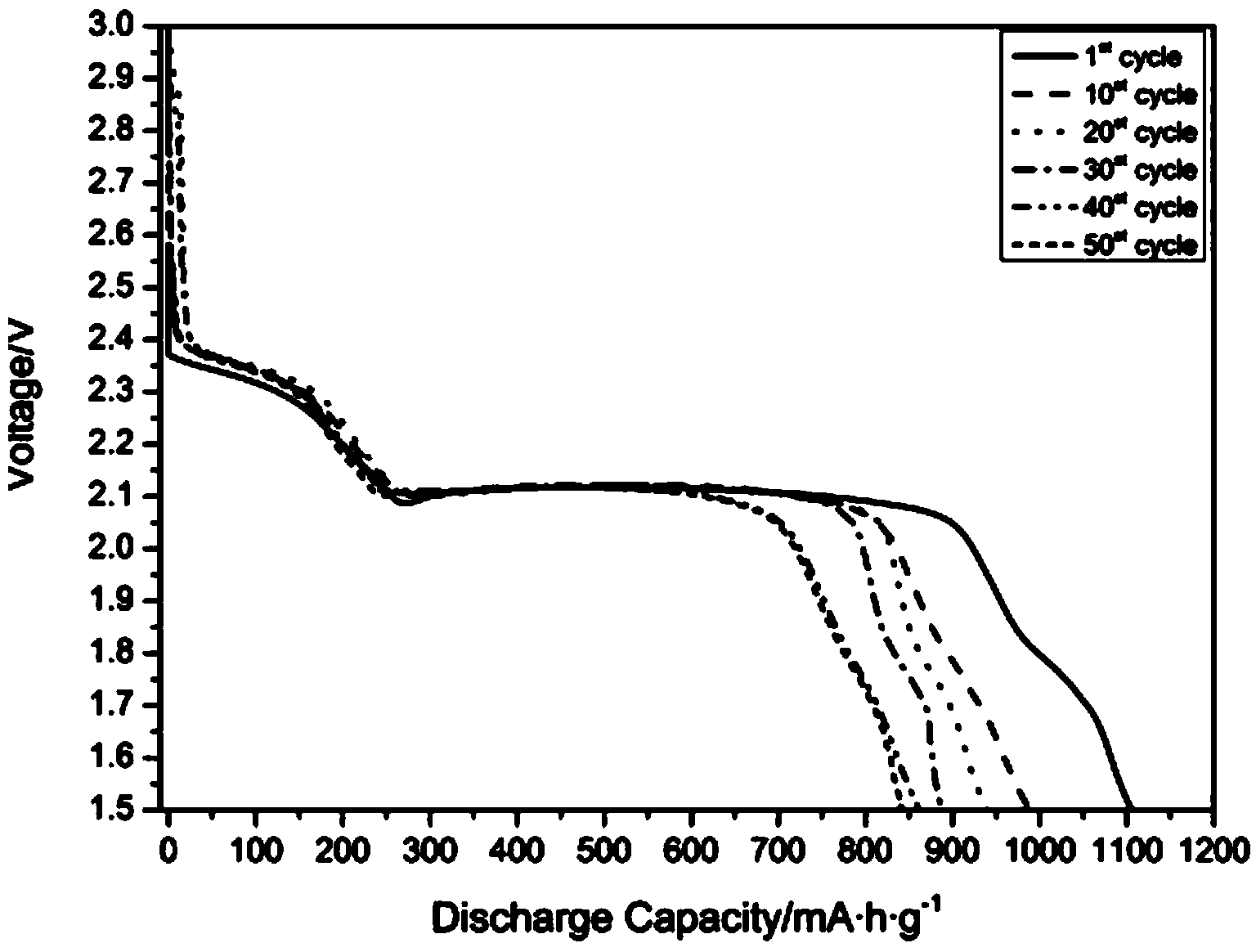

[0033] The additive provided in this example is a composite material of 2.5g of glucose (Glucose) and 1g of Super P, and the preparation method is the same as that of Example 1. The prepared additive is added to the C / S system, and the composite method is the same as that in the comparative example, that is, a C / S / Glucose composite positive electrode material is obtained, and in the positive electrode material, C: 58wt%, S: 40.00wt%, additive: 2.00 wt%. The methods of preparing the positive electrode sheet, assembling the battery and testing the battery are the same as those in the comparative example. The battery constant current charge and discharge test shows that the first discharge specific capacity is: 1106mAh g -1 . Specific capacity after 50 cycles: 843mAh g -1 , the specific capacity after 100 cycles is 821mAh·g -1 . see results figure 2 shown. Compared with the battery without additives, the discharge specific capacity and cycle stability of the battery are g...

Embodiment 3

[0035] The additive provided in this example is a composite material of 1 g of glucose (Glucose) and 1 g of Super P, and the preparation method is the same as that of Example 1. The prepared additive is added to the C / S system, and the composite method is the same as that in the comparative example, that is, a C / S / Glucose composite positive electrode material is obtained, and in the positive electrode material, C: 58wt%, S: 40.00wt%, additive: 2.00 wt%. The methods of preparing the positive electrode sheet, assembling the battery and testing the battery are the same as those in the comparative example. The battery constant current charge and discharge test shows that the first discharge specific capacity is: 1123mAh g -1 . Specific capacity after 50 cycles: 849mAh·g -1 , specific capacity after 100 cycles: 815mAh·g -1 . Compared with the battery without additives, the discharge specific capacity and cycle stability of the battery are greatly improved after adding glucose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com