Efficient switch-back type car dumper unloading system

A dumper and switchback technology, which is applied in the field of switchback dumper unloading system, can solve the problems of low operating efficiency, long working site, and wide land occupation, and achieve simple and efficient unloading system, automatic operation, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

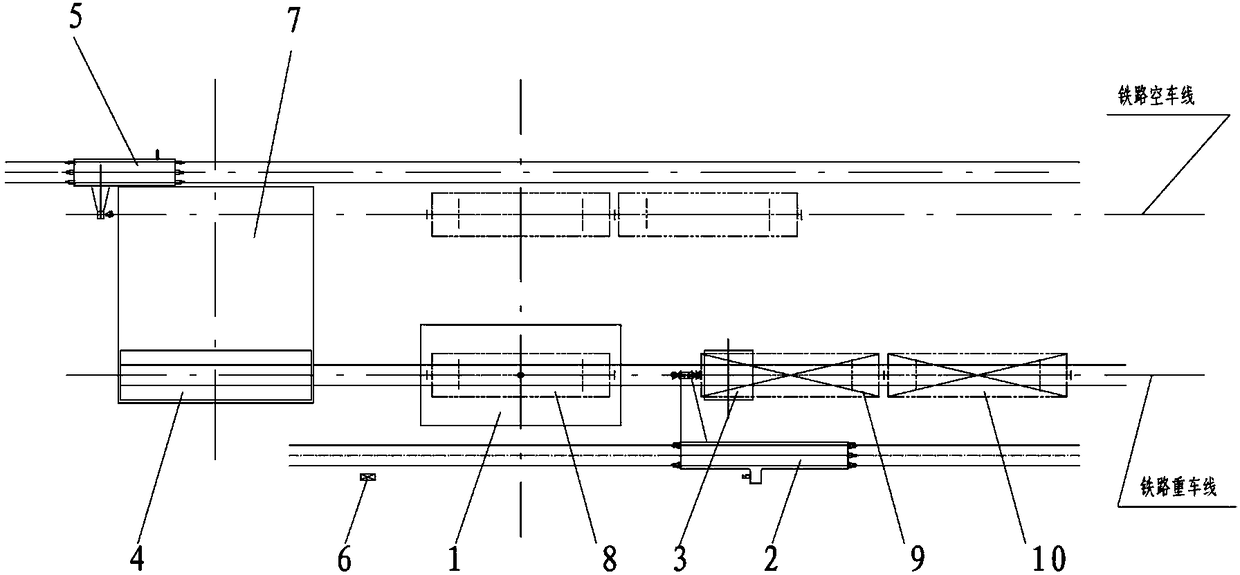

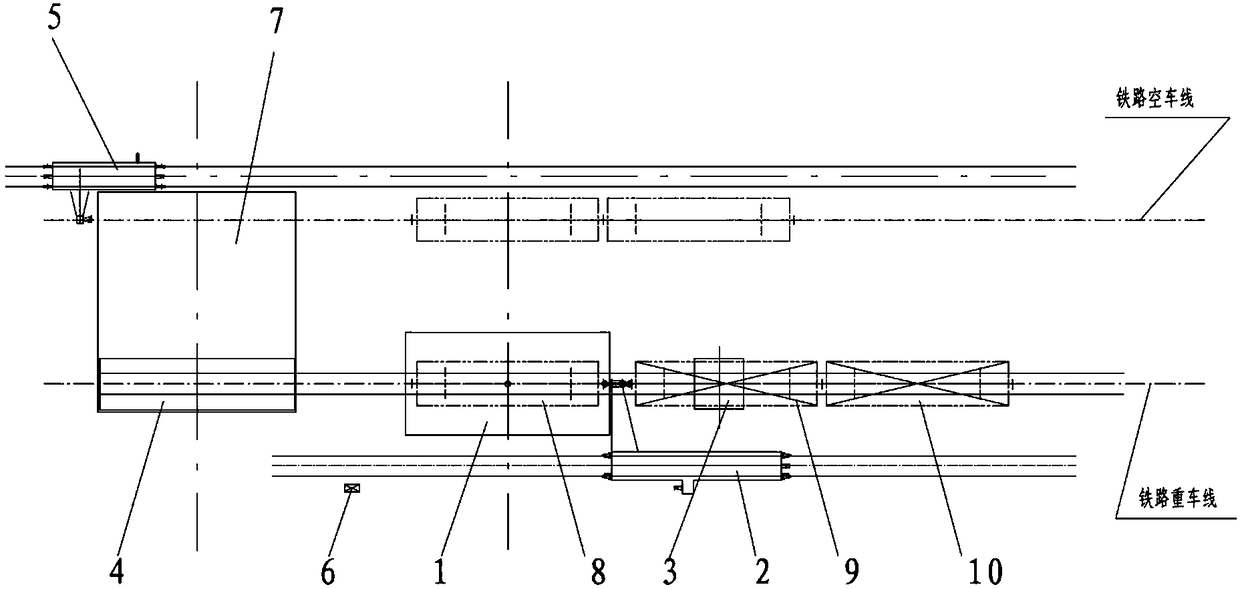

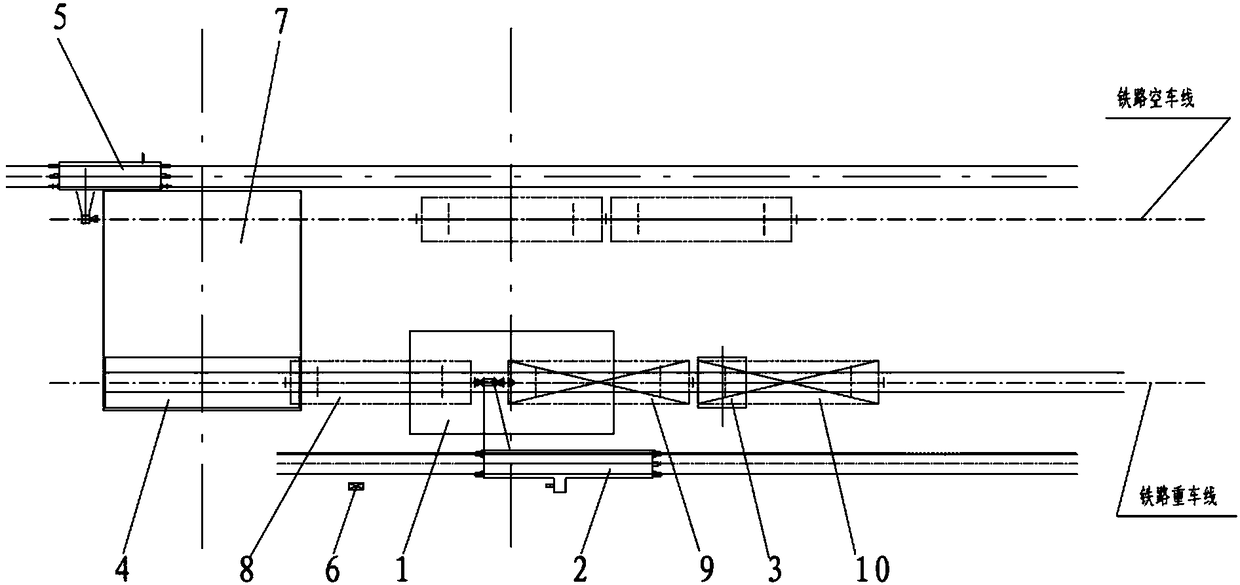

[0041] The present invention will be further described below in conjunction with drawings and embodiments.

[0042] A high-efficiency turn-back dumper unloading system, including a dumper 1, a steering machine 2, a wheel gripper 3, a vehicle moving platform 4, a cart pusher 5, an auxiliary shunting machine 11, and 1# movable stoppers 12 and 2# Movable stopper 13 and shifting machine travel stopper 14, dumper 1 is located on railway heavy car line, and heavy car is the wagon row that goods are housed, and heavy car row is placed at the rear of dumper 1, and a part of railway heavy car line The railway empty car line is set on one side, and the shifter line is set on the other side. The shifter 2 is arranged on the shifter line, and is used to pull the heavy trains to move forward. The moving platform 4 is located in front of the dumper 1. Platform 4 moves between the railway heavy train line and the railway empty train line, and is used to move the unloaded empty train from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com