Machine for forming paper container

A technology for forming machines and paper containers, applied in the direction of cardboard winding articles, etc., can solve the problems of limiting the production speed of products, harmful to the health of operators, unable to meet the requirements of increasing production and saving expenses, etc., to avoid ultrasonic radiation, improve work efficiency, and improve finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

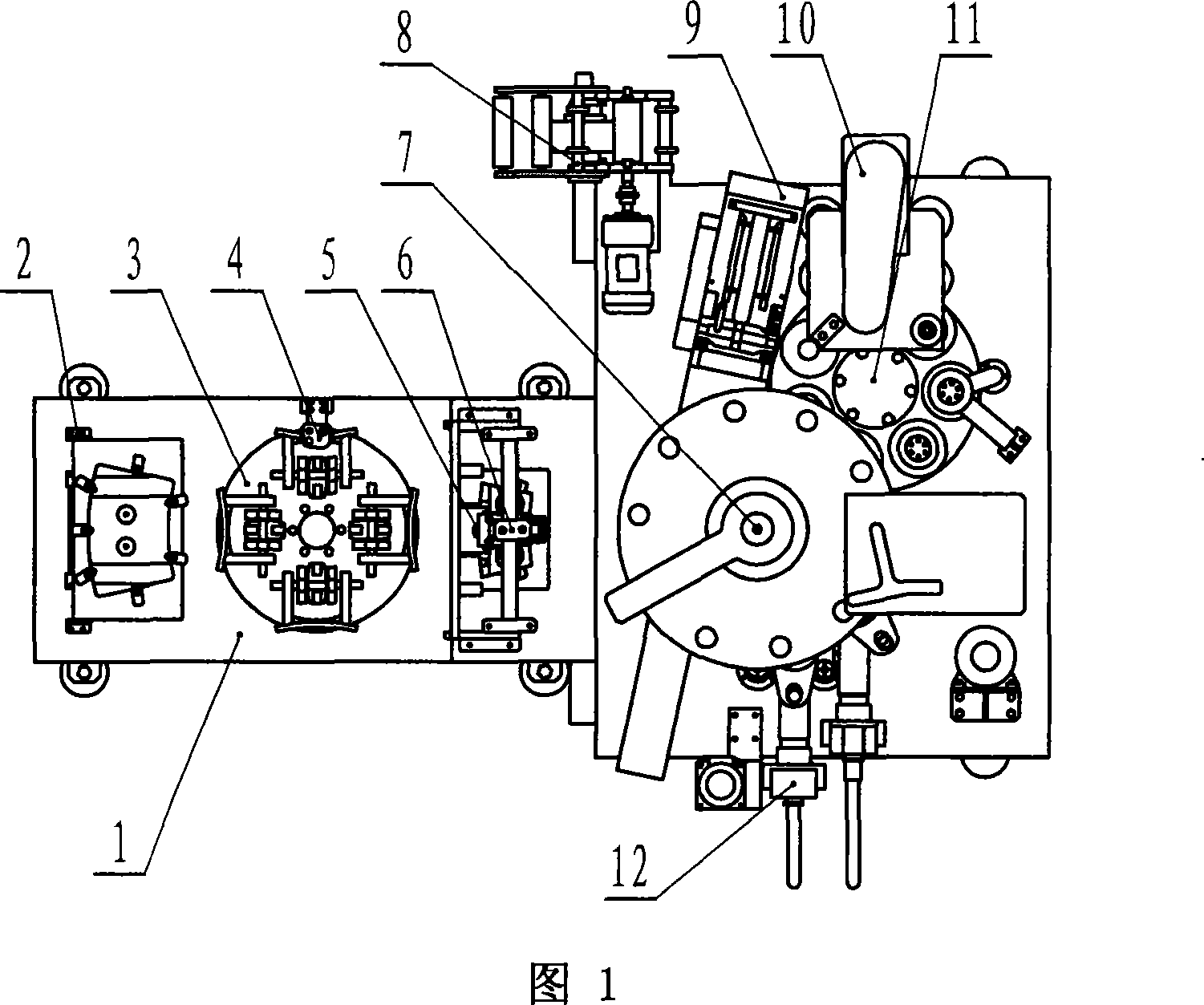

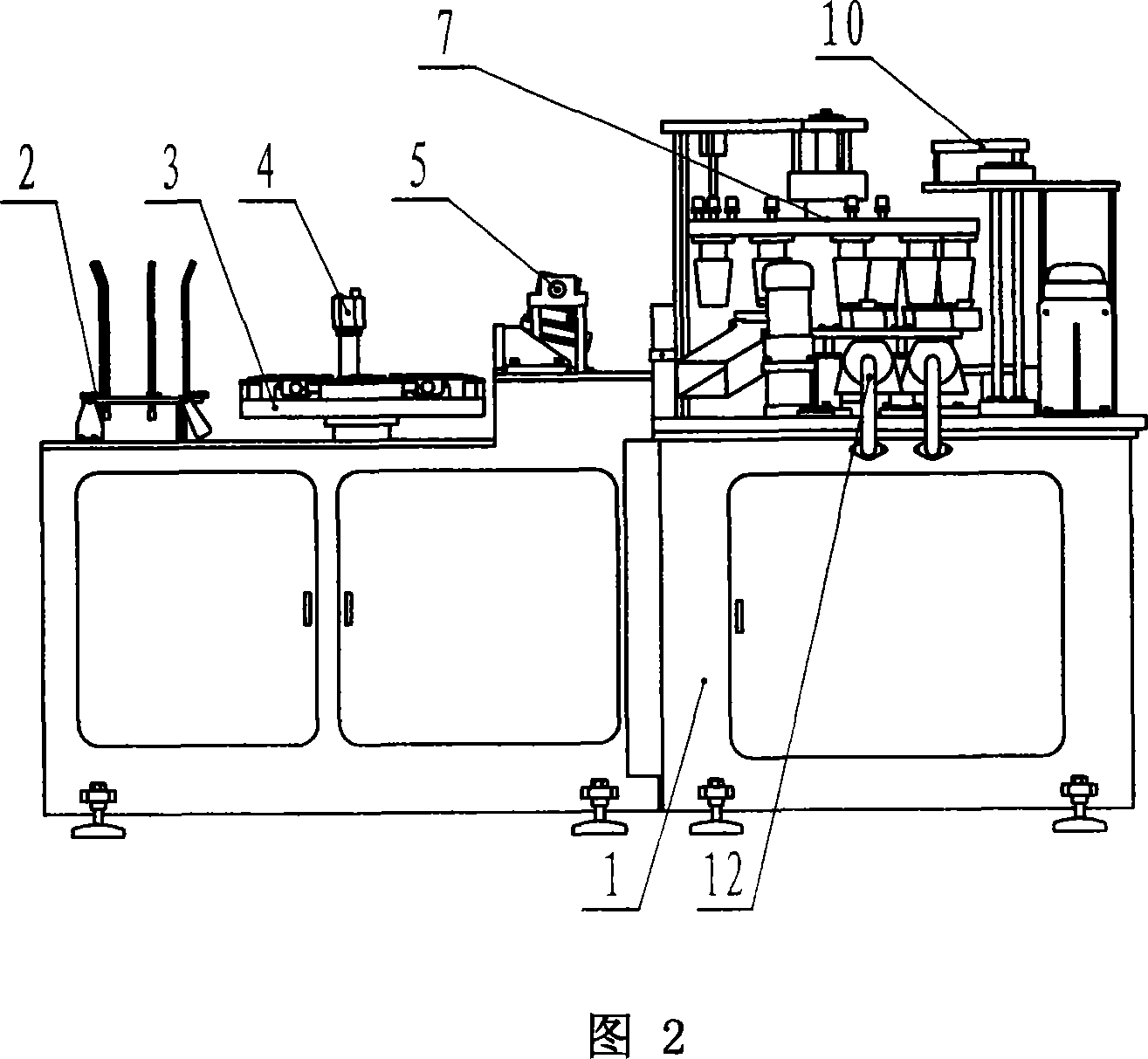

[0023] As shown in Fig. 1 and Fig. 2, the paper container forming machine among the present invention comprises frame 1, is provided with paper feeding device 2, feeding tray 3, side wall preheating device 4, side wall forming device 5, Side wall bonding device 6 , bottom edge preheating device 12 , bottom edge forming device 7 , bottom edge bonding device 10 , bottom paper conveying device 8 , bottom paper feeding device 9 and bottom edge strengthening device 11 . The frame 1 is provided with a motor and a transmission mechanism. Wherein, the paper feeding device 2, the feeding tray 3 and the side wall forming device 5 are sequentially arranged on the front part of the frame 1, the side wall preheating device 4 is fixed on the frame 1 corresponding to the position of the feeding tray 3, and the side wall is glued to the frame 1. The closing device 6 corresponds to the side wall forming device 5 and is provided. Bottom edge preheating device 12 , bottom edge forming device 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com