Crank-connecting rod mechanism for engine of miniature cross-country motorcycle

A technology of crank connecting rod mechanism and motorcycle, which is applied in the direction of variable capacity engine, machine/engine, reciprocating piston engine, etc. High torque, high crankshaft speed, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

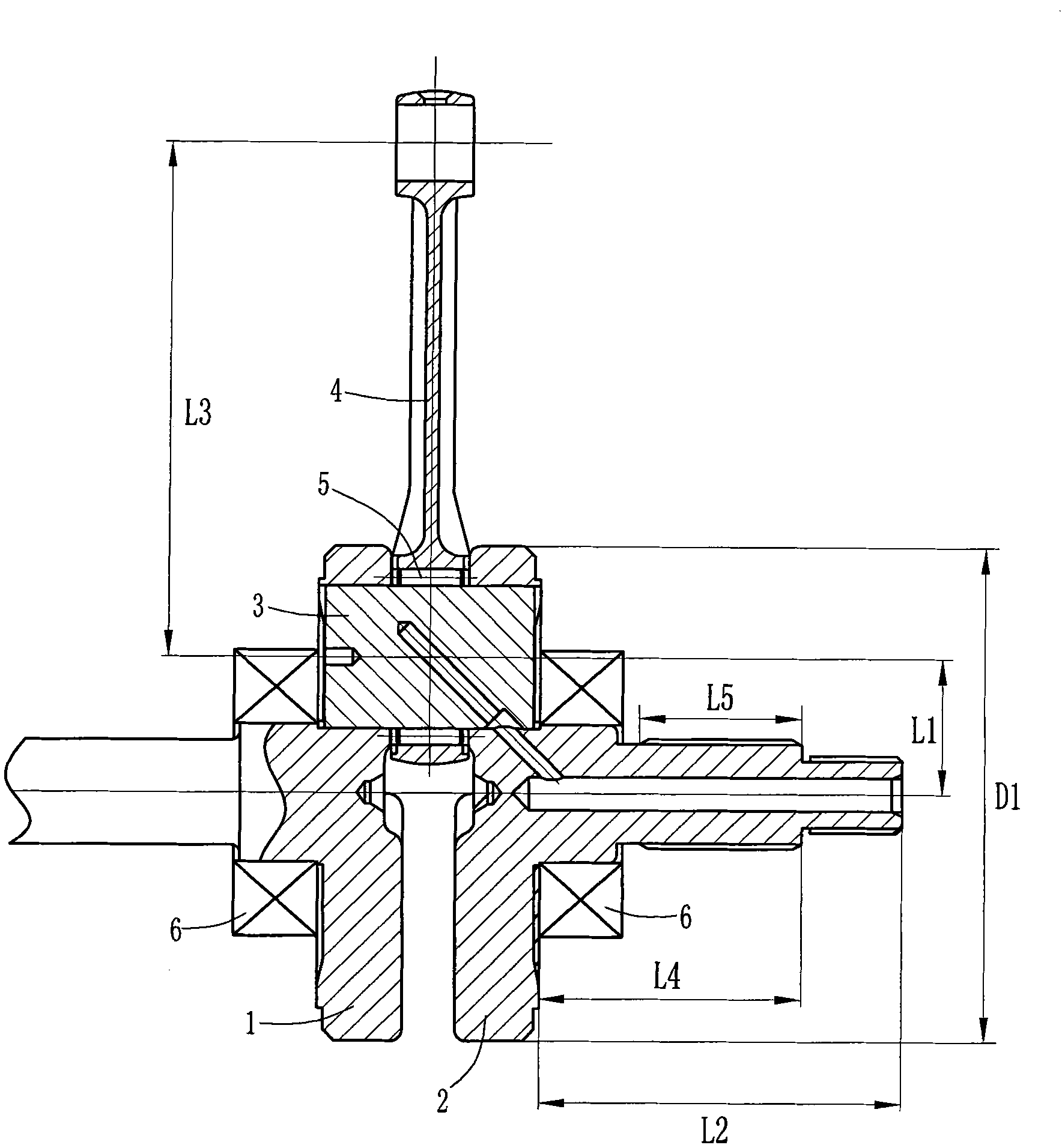

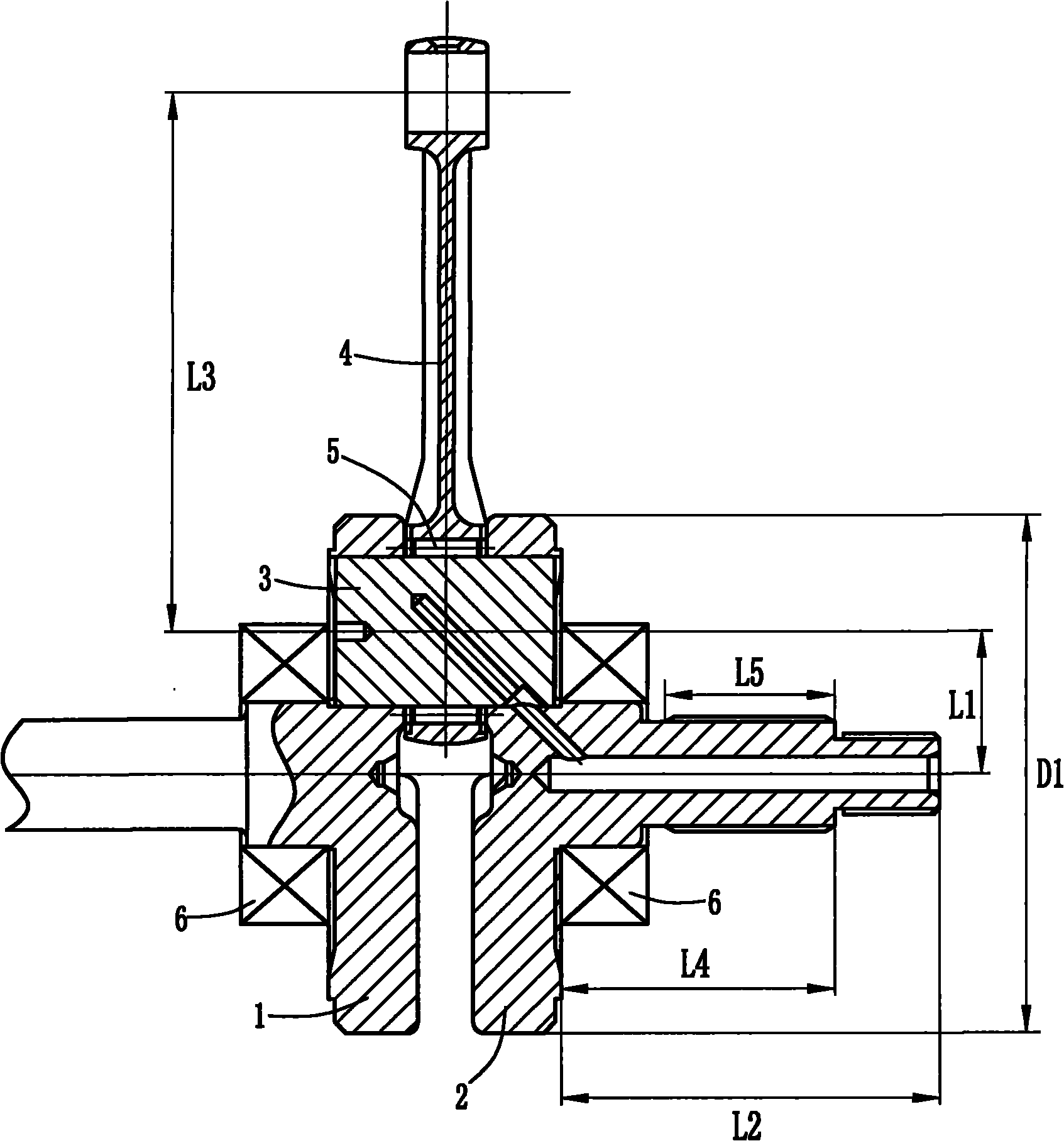

[0011] Such as figure 1 As shown, the present invention is made of components such as left crank 1, right crank 2, crank pin 3, connecting rod 4, connecting rod big end bearing 5 and crank bearing 6, and the structure of each component is the same as the prior art, and will not be repeated here . Described left and right cranks 1,2 are symmetrically distributed on both sides of connecting rod 4 large ends, and crank bearings 6 are equipotentially pressed on left and right cranks 1,2. The left and right cranks 1 and 2 are connected to the big end of the connecting rod 4 through the crank pin 3, and the connecting rod big end bearing 5 is installed in the mounting hole of the connecting rod 4 big end, and the connecting rod big end bearing 5 is assembled on the crank pin 3 .

[0012] From figure 1 It can be seen from the figure that the center-to-center dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com