Turning-back type car dumper unloading system with static scale

A dumper and turn-back technology, which is applied in the field of the dumper unloading system of the turn-back dumper, can solve problems such as low work efficiency and achieve the effect of avoiding delayed fines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

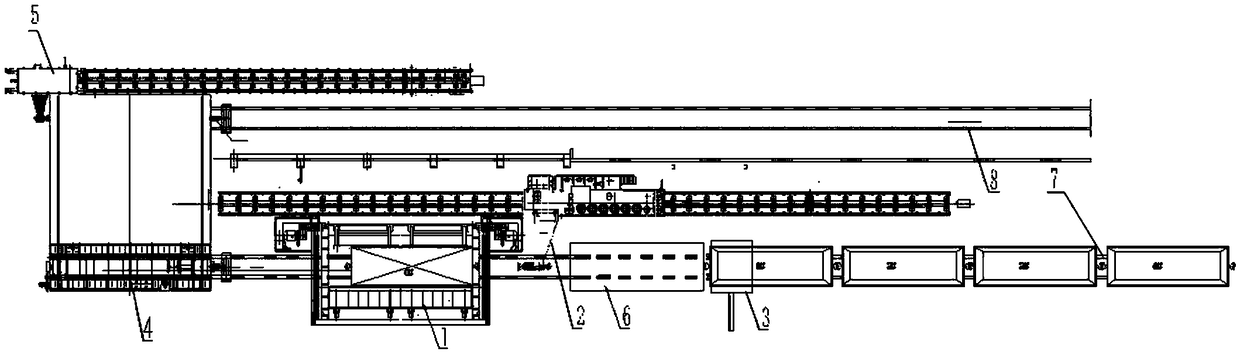

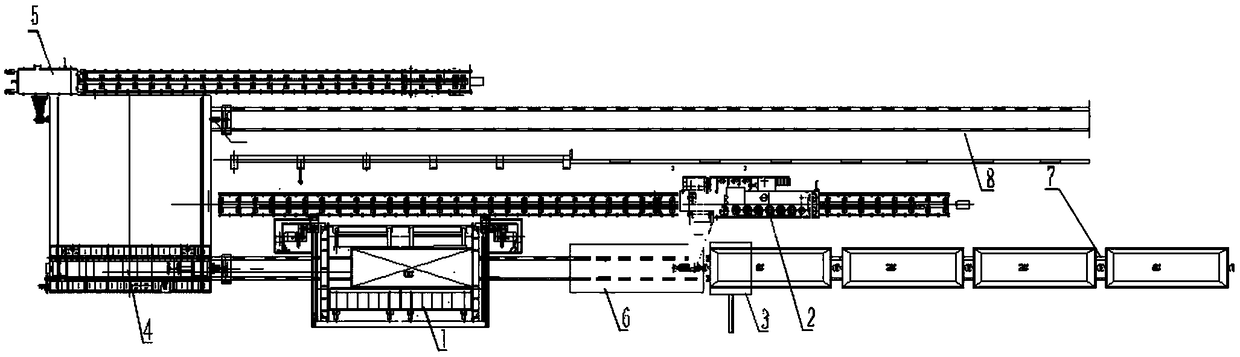

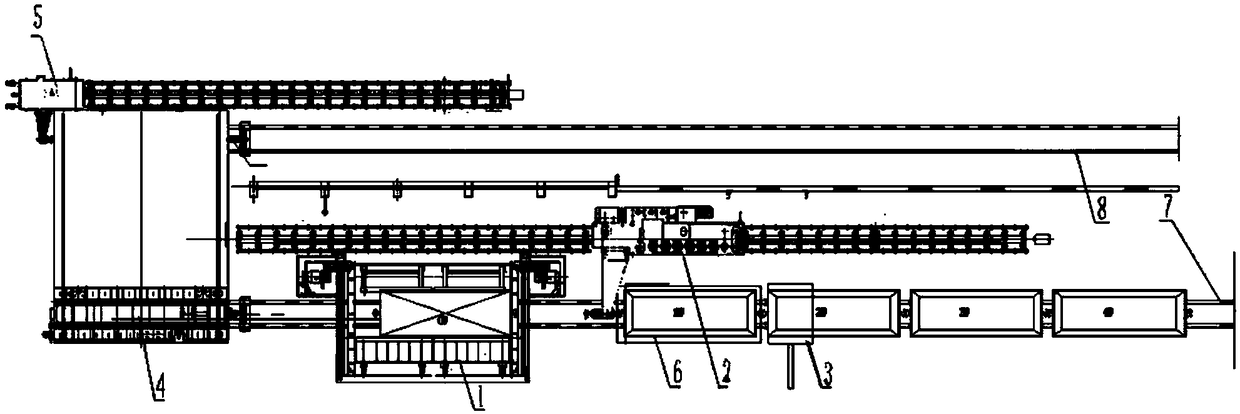

[0025] Such as Figure 5 As shown, a turn-back type dumper unloading system with a static balance includes a dumper 1, a turner 2, a wheel gripper 3, a moving platform 4, a pusher 5 and a static scale 6, and the dumper 1 and The static scale 6 is set on the heavy railway line 7, the static scale 6 is placed behind the dumper 1, the wheel gripper 3 is placed behind the static scale 6, and the empty railway line 8 is arranged on one side of the heavy railway line 7. The shifting machine 2 is used to pull the heavy trains to move forward, the moving platform 4 is located in front of the dumper 1, the moving platform 4 moves between the heavy railway line 7 and the empty railway line 8, and the cart 5 is located on the One side of the railway empty car line 8, the empty cars are assembled on the empty car line 8, the wheel gripper 3 is located on the railway heavy car line 7, and is positioned at the rear of the static scale 6, and the parking space of the puller 2 is set at Betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com