Sensor with large working stroke and small size

A technology with small working stroke and small volume, applied in the field of sensors, can solve the problems of large and small volume, unable to realize working stroke, limit the application of linear displacement sensors, etc., and achieve the effect of reducing working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

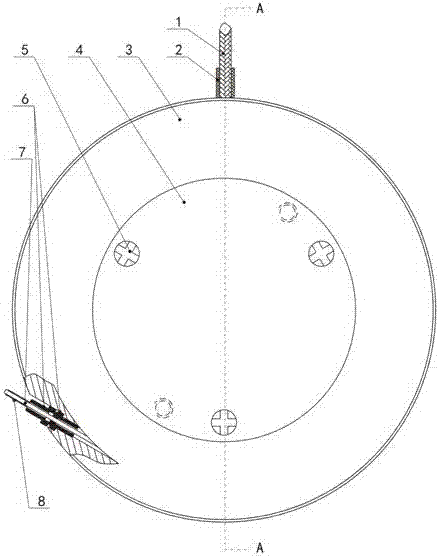

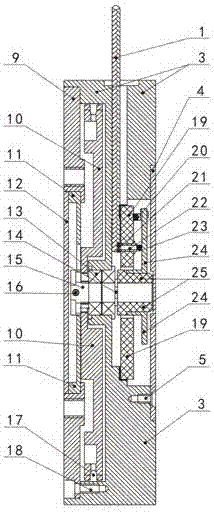

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] Such as figure 1 with figure 2 As shown, the sensor of the present invention with a large working stroke and a small volume includes a housing 3, a resistor body 19, a brush, a collector ring 24, a lead terminal 22, a lead wire 1, a flexible stainless steel wire rope 7, a rotating shaft 15, and a shaft disk 10. Bearing 13 and insulating sleeve 25. The brushes include a first brush 20 and a second brush 23. The first brush 20 and the second brush 23 are respectively installed on the collector ring 24 and can be connected with the resistor One side of the body 19 is in contact with the surface, the distance between the first brush 20 and the axis line of the insulating bushing 25 is different from the distance between the second brush 23 and the axis line of the insulating sleeve 25, and the resistor body 19 The lead wire 1 is connected to the lead wire 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com