Step-by-step direct-action electromagnetic operating valve with wide working range

A working range, electromagnetic actuation technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of large structure size and mass, the engine system cannot provide external control air source, and the electric valve solution cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

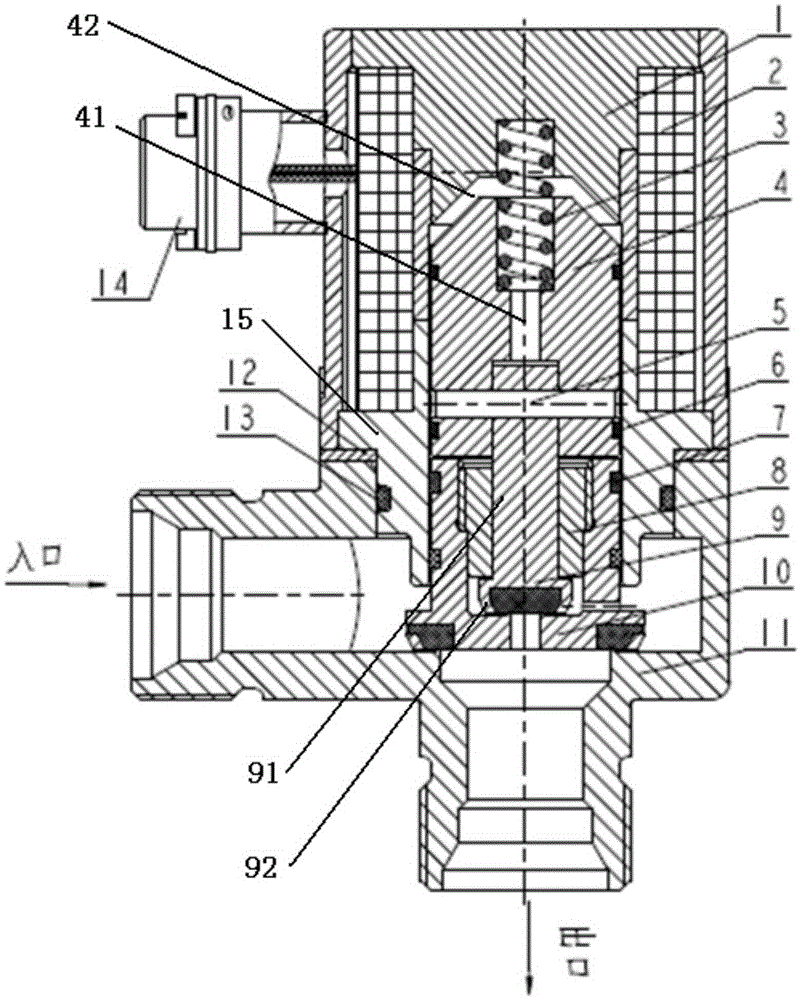

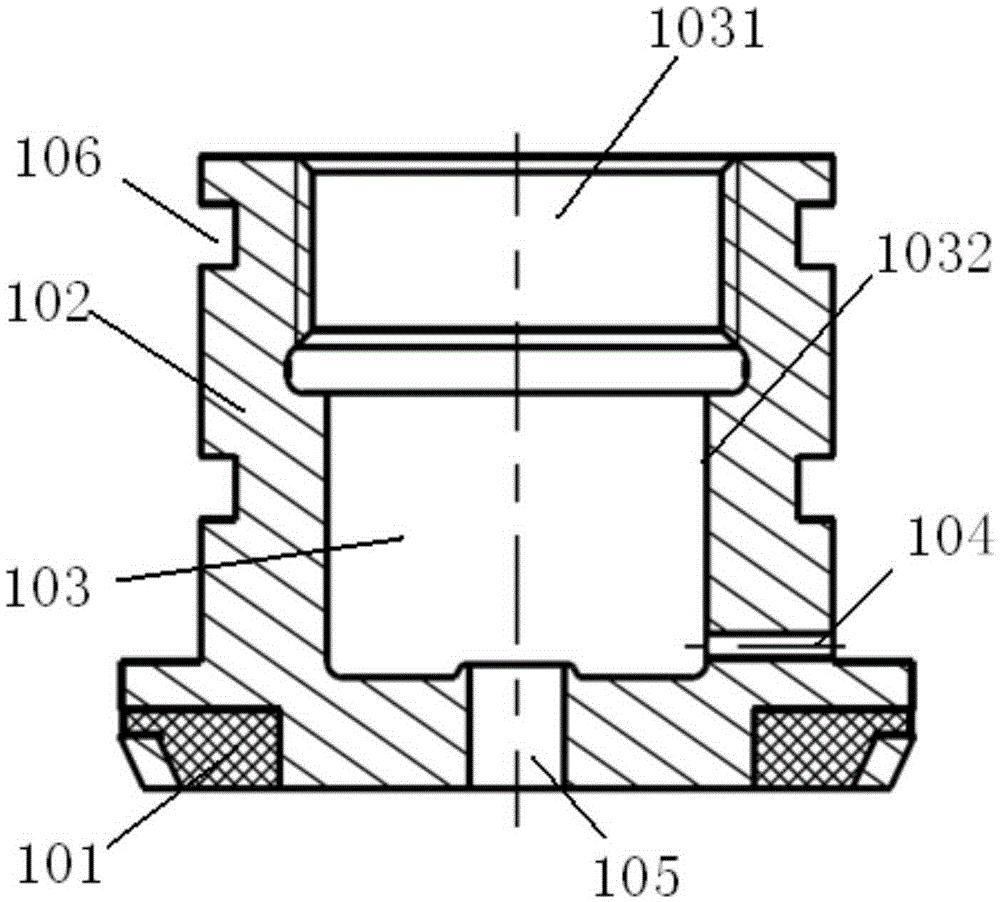

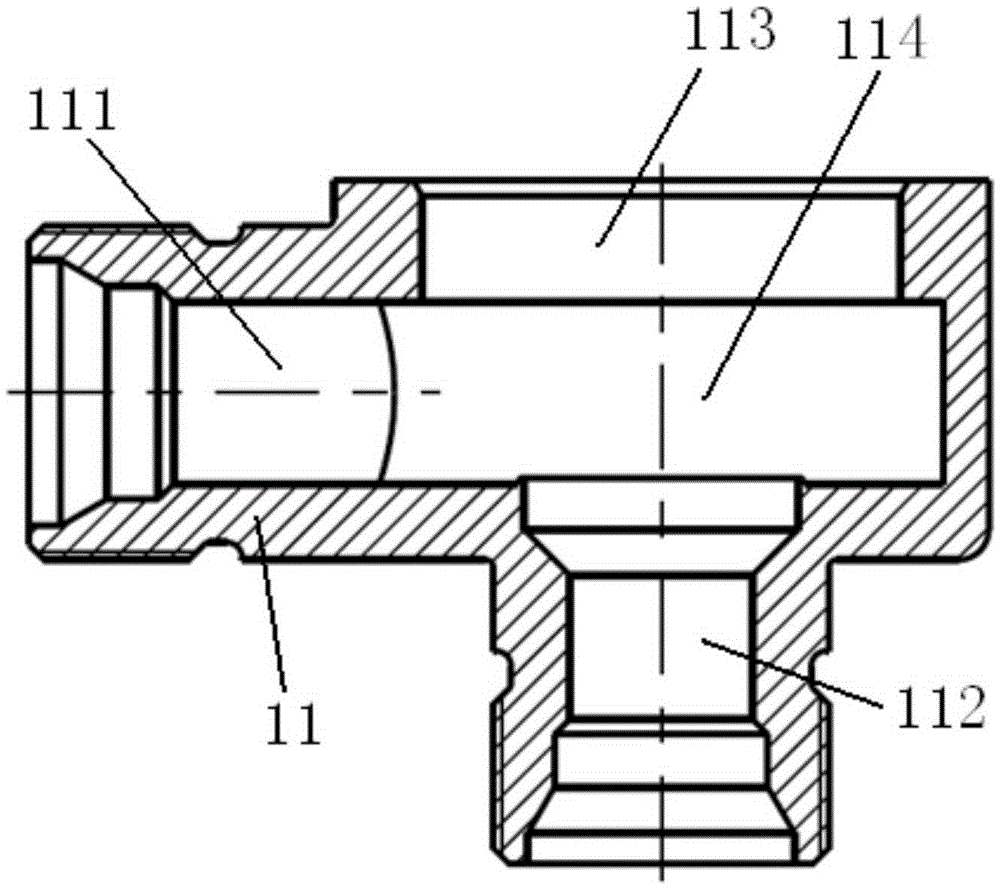

[0037] Such as figure 1 As shown, it is a step-by-step direct-acting electromagnetic actuated valve structure with a wide working range of the present invention, which consists of a valve body 1, a coil 2, a spring 3, an armature 4, a pin shaft 5, a wear-reducing ring 6, a sealing ring 7, The guide sleeve 8, the guide valve core 9, the main valve core 10, the housing 11, the adjusting gasket 12, the rubber O-ring 13 and the socket 14 etc. are composed.

[0038]The working mode of this product is to open when the power is turned on and to close when the power is off. When the valve is not working, the medium enters the upper cavity 42 of the main valve core through the orifice 104 on the main valve core, and provides sealing force for the main valve core 10 together with the spring force. Ensure reliable sealing of the spool. When there is no pressure difference between the inlet and the outlet, after the coil is energized, the electromagnetic attraction overcomes the spring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com