Nuclear class II film pneumatic bellows stop valve

A bellows stop valve and bellows technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of not being able to close the valve quickly and automatically, large parts of the pneumatic device, and large external dimensions, etc., and achieve compact structure and long working stroke The effect of small, short strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

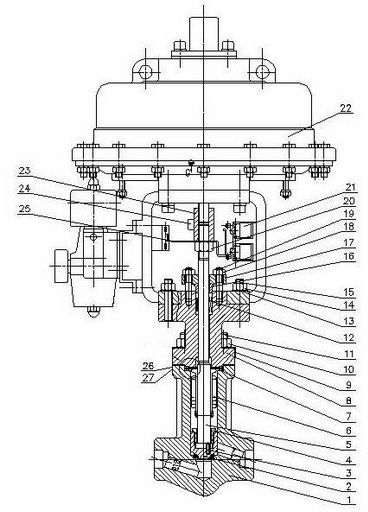

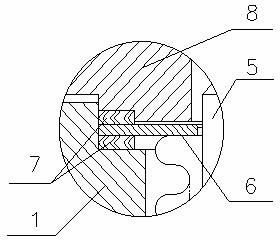

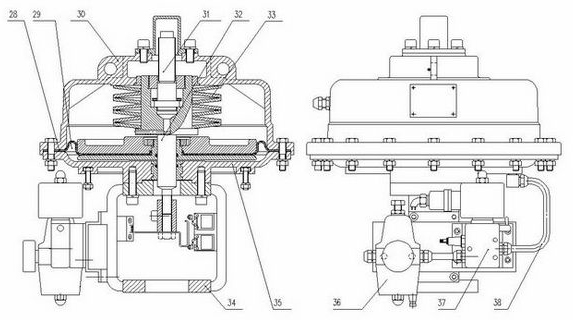

[0016] figure 1 , figure 2 and image 3 In the schematic diagram of the nuclear secondary membrane pneumatic bellows stop valve shown, the valve body 1 and the valve cover 8 clamp two wound gaskets 7 and one end of the bellows 6, and the valve stem 5 and the bellows 6 are worn in the middle, and the bellows The other end of the pipe 6 is connected with the valve stem 5, and the end of the valve stem 5 is connected with the valve clack 2, the positioning pin 3, and the valve clack pressure sleeve 4, and the valve stem 5 is connected to the pneumatic The device 22 is connected, and under the drive of the pneumatic device 22 and the opening and closing nut 23, the screw 24, and the lock nut 20 of the connecting piece, the closing and opening of the sealing surface between the valve disc 2 and the valve body 1 is realized; the pneumatic device 22 and the valve cover 8 Fasten with middle flange stud 9, middle flange nut 10 and anti-loosening washer 11, packing 12 is installed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com