Garbage compaction complete equipment

A complete set of equipment and garbage compression technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of poor adaptability, low space utilization rate of garbage stations, and inability to meet the needs of 31-ton transfer vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

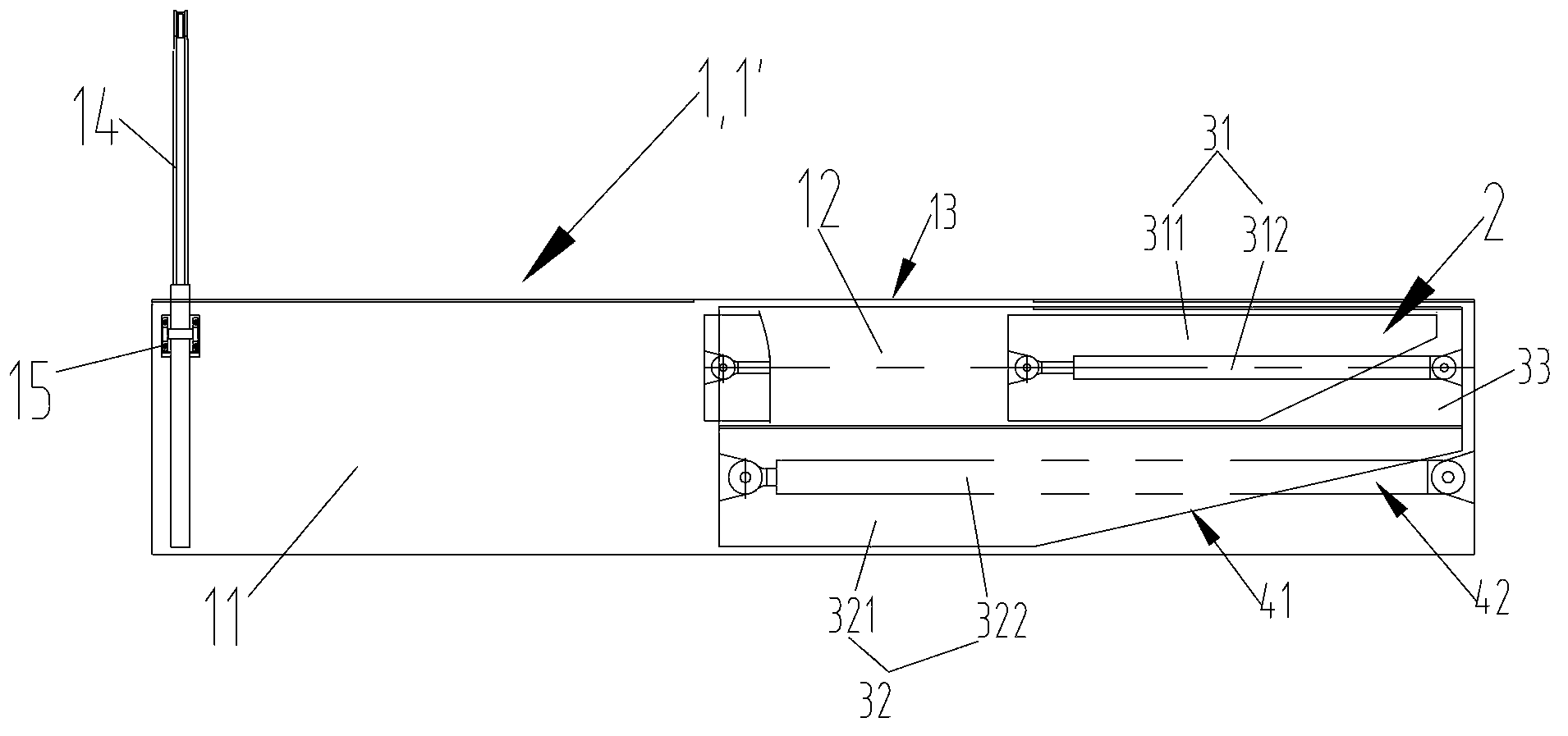

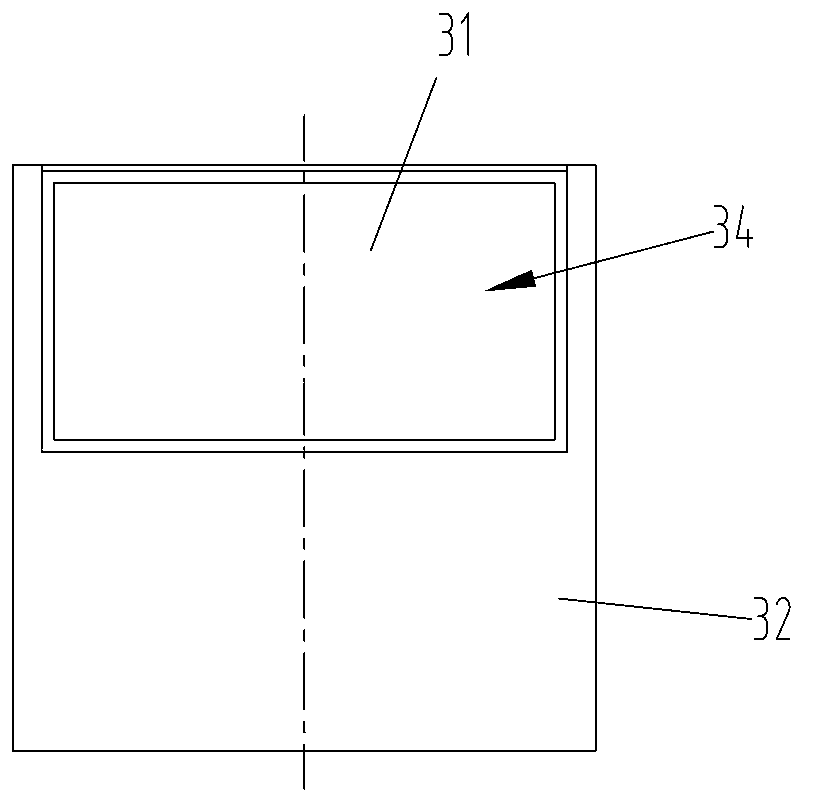

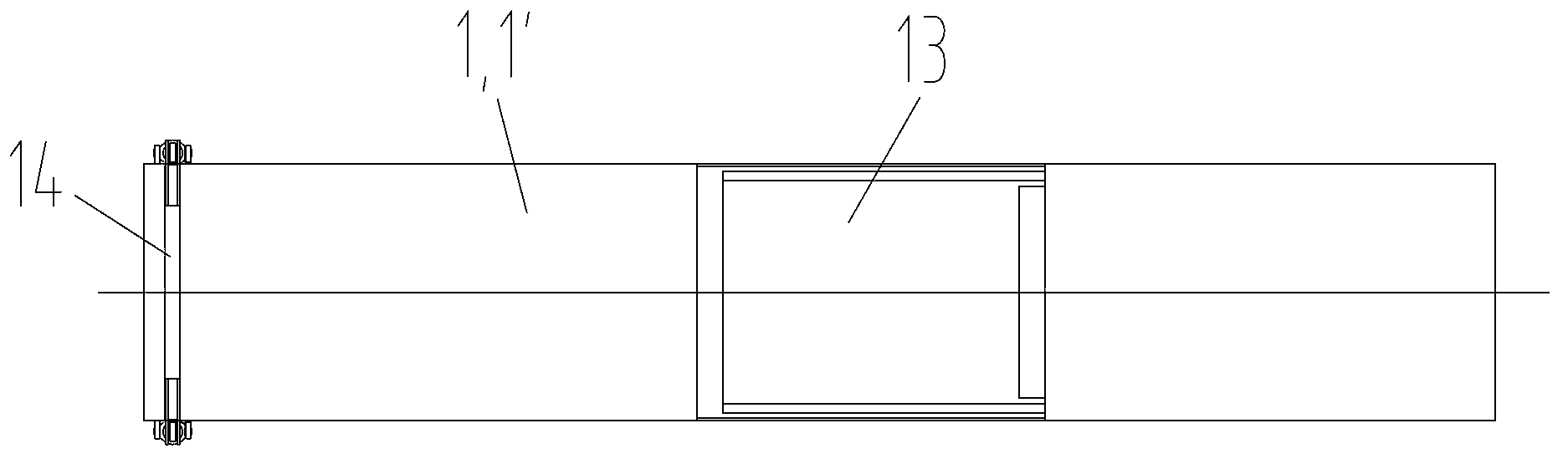

[0072] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0073] In the present invention, under the situation of not stating to the contrary, the orientation words used such as "up, down, height direction, length direction" are usually under the normal use situation of the garbage compressor provided by the invention and the garbage unloading equipment. Defined, and in the present invention, the direction of movement of garbage is defined as "moving from back to front", specifically refer to figure 1 , Figure 4 , Figure 6 , Figure 11 and Figure 14 Therefore, the "longitudinal direction" and the "front-rear direction" are the same, and both are the "left-right direction" in the above-mentioned direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com