Synchronous core-pulling mechanism on the inner and outer sides of the injection mold for automobile wheel covers

A technology of injection mold and core-pulling mechanism, which is applied in the field of synchronous core-pulling mechanism on both sides of the inside and outside, can solve the problems of high mold cost, high production cost, complex mechanism, etc., and meet the requirements of shortening the working schedule and shortening the work opening The effect of simplifying the drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

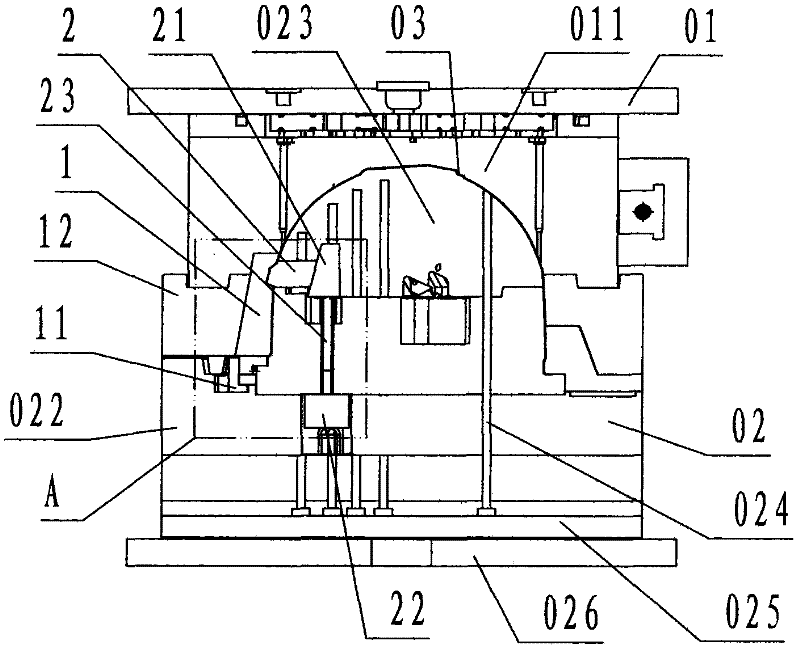

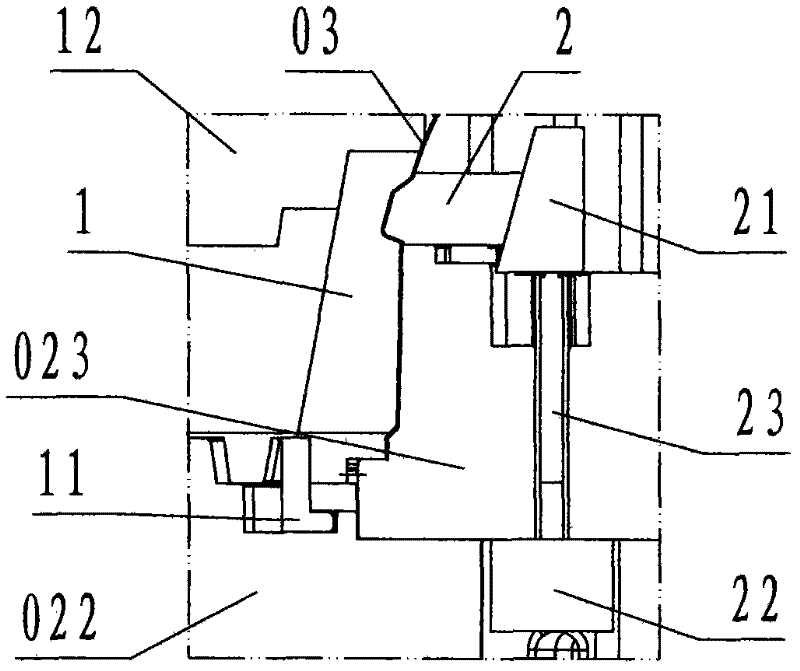

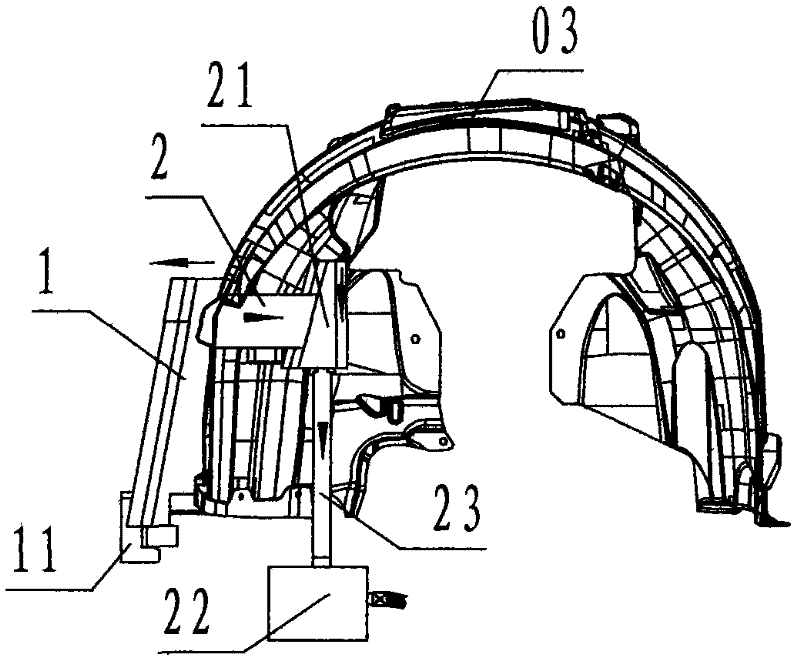

[0024] refer to Figure 1 ~ Figure 3 , a synchronous core-pulling mechanism on both sides of the inner and outer sides of an automobile wheel cover injection mold according to the present invention, comprising an outer core-pulling slider 1, an oblique guide block 12, an inner core-pulling slider 2, an oblique wedge slider 21, an oil cylinder 22, a connecting Rod 23, wherein: the outer core-pulling slider 1 is a steel block with a rectangular top view projection and a trapezoidal trapezoidal shape with a small top and a large bottom bottom in a side view projection. One side of the outer core-pulling slider 1 is a slope, so The T-shaped groove along the inclined plane direction on the slope is called the chute side, and the side opposite to the chute side is called the profile side. The core-pulling profile, the bottom surface of the outer core-pulling slider 1 is provided with a hook 11 composed of an L-shaped right-angled hook-shaped block, and the opening of the hook groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com