Pilot high-pressure valve

A technology of pilot valve and high-pressure valve, applied in the field of high-pressure valve, can solve the problems of long switching time, poor stability, low quality of plastic bottles, etc., and achieve the effect of long service life and high integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

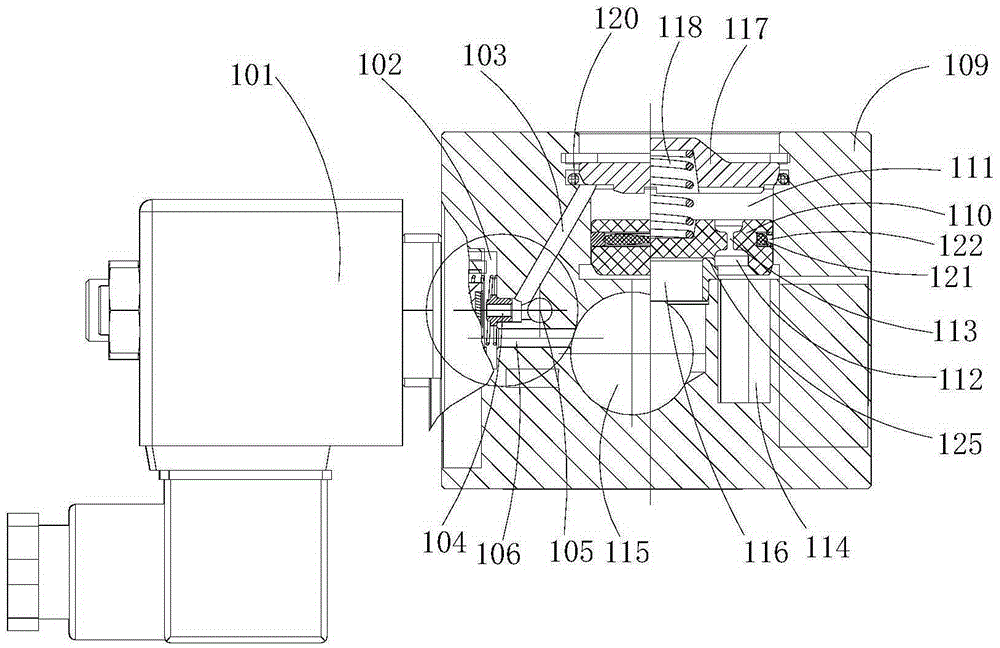

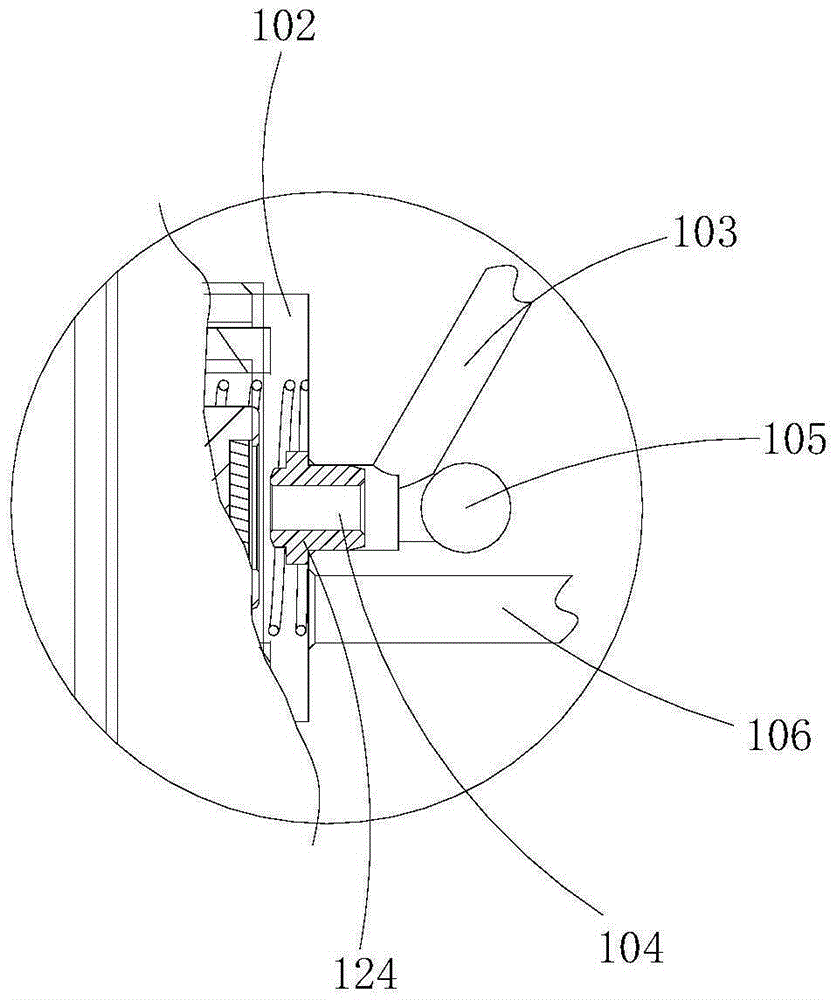

[0068] Example 1, such as figure 1 , figure 2 with Figure 5 as shown,

[0069] A pilot-operated high-pressure valve, including a pilot valve 101 and a main valve, the main valve includes a cylinder 109, a piston 110, a main valve inlet 114 and a main valve outlet 115, and the piston 110 transfers the air in the cylinder 109 The space is divided into an upper chamber 111 and a lower chamber 112, a through hole 113 is provided between the upper chamber 111 and the lower chamber 112, the lower chamber 112 communicates with the main valve air inlet 114, and the main valve The air outlet 115 is arranged on the lower end surface of the piston 110;

[0070] The pilot valve 101 is provided with a pilot valve chamber 102 and a spool 1012, the pilot valve chamber 102 is provided with a pilot valve port 104 at a position corresponding to the spool 1012, and the pilot valve 101 is provided with The pilot valve inlet 103 and the pilot valve channel 105, the pilot valve channel 105 co...

Embodiment 2

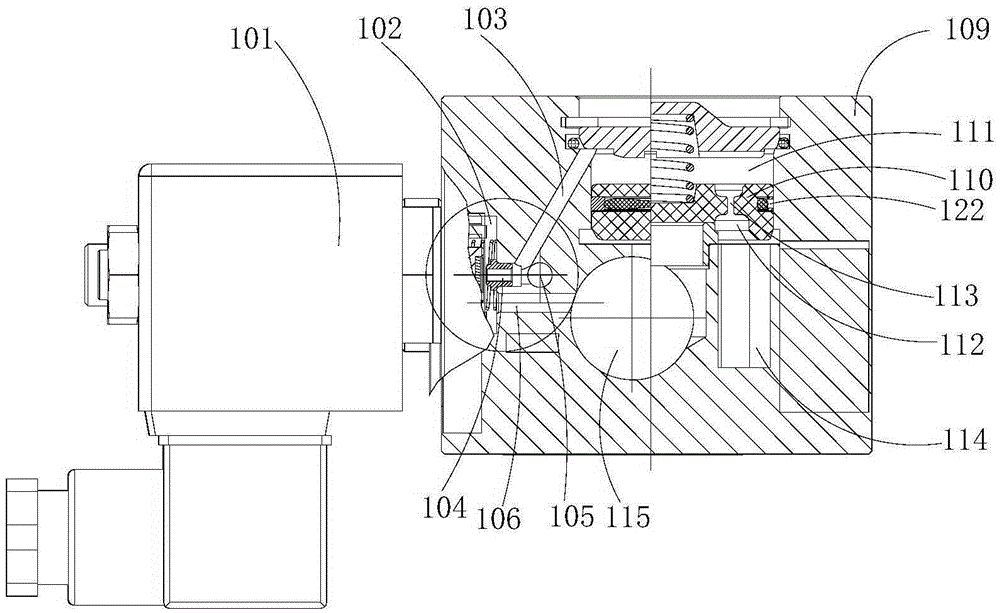

[0072] Example 2, such as image 3 with Figure 4 as shown,

[0073] A pilot-operated high-pressure valve, including a pilot valve 101 and a main valve, the main valve includes a cylinder 109, a piston 110, a main valve inlet 114 and a main valve outlet 115, and the piston 110 transfers the air in the cylinder 109 The space is divided into an upper chamber 111 and a lower chamber 112, a through hole 113 is provided between the upper chamber 111 and the lower chamber 112, the lower chamber 112 communicates with the main valve air inlet 114, and the main valve The air outlet 115 is arranged on the lower end surface of the piston 110;

[0074] The pilot valve 101 is provided with a pilot valve chamber 102 and a spool 1012, the pilot valve chamber 102 is provided with a pilot valve port 104 at a position corresponding to the spool 1012, and the pilot valve 101 is provided with The pilot valve inlet 103 and the pilot valve channel 105, the pilot valve channel 105 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com