High temperature plug valve

A valve, high temperature technology, applied in the field of valve production, can solve the problems of lack of online maintenance, insufficient high temperature resistance, short service life, etc., and achieve the effect of short opening and closing time, long life and less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

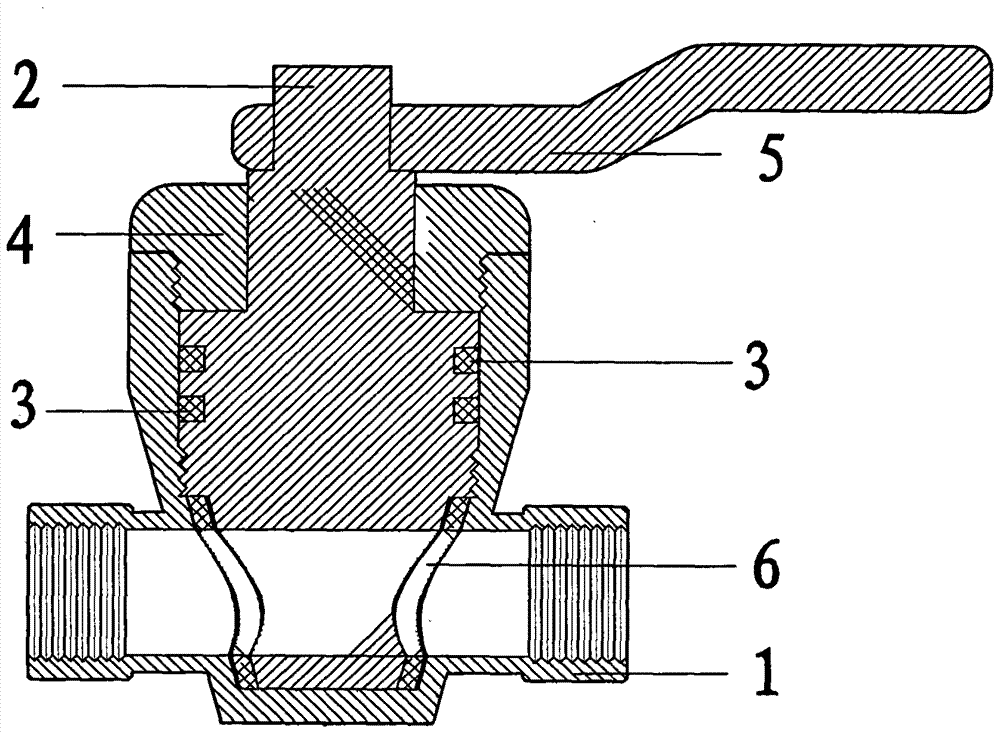

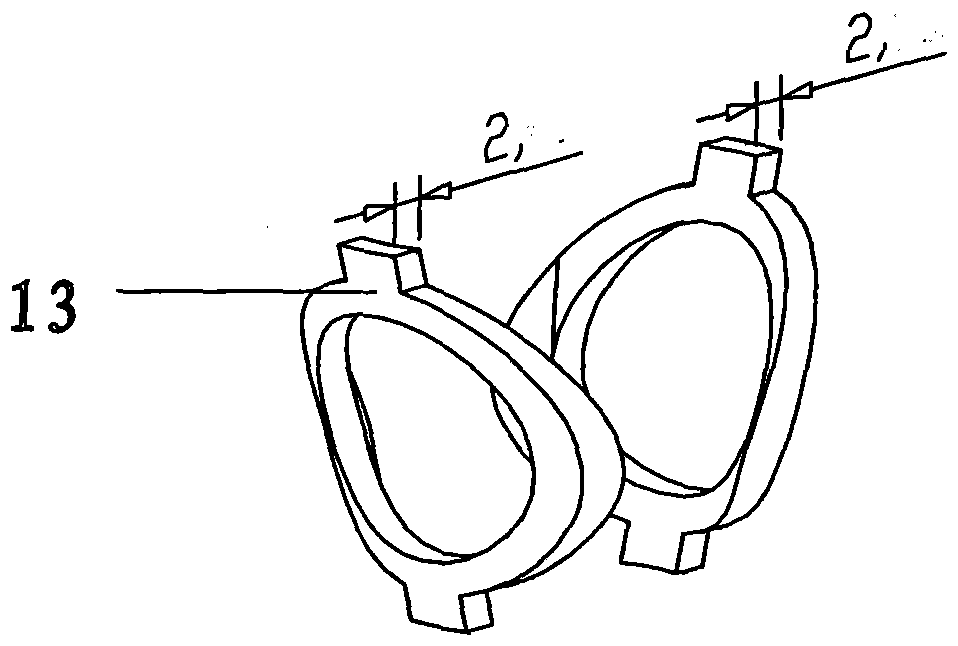

[0017] First, the valve body (1) is mold-cast first, and the passage hole of the fluid is drilled on the upper rotary bed, and the two hexagons at the two ends of the valve body are milled out by a milling machine, and then all the threads on the valve body are processed on a lathe. Then machine the tapered surface of the valve body on a lathe. After getting off the bed, the cone surface has to be ground to a mirror surface precision. The inner wall of the inner cavity of the valve body and the periphery (16) of the metal expansion ring (3) is in contact with each other, and the manufacturing grade is a mirror surface.

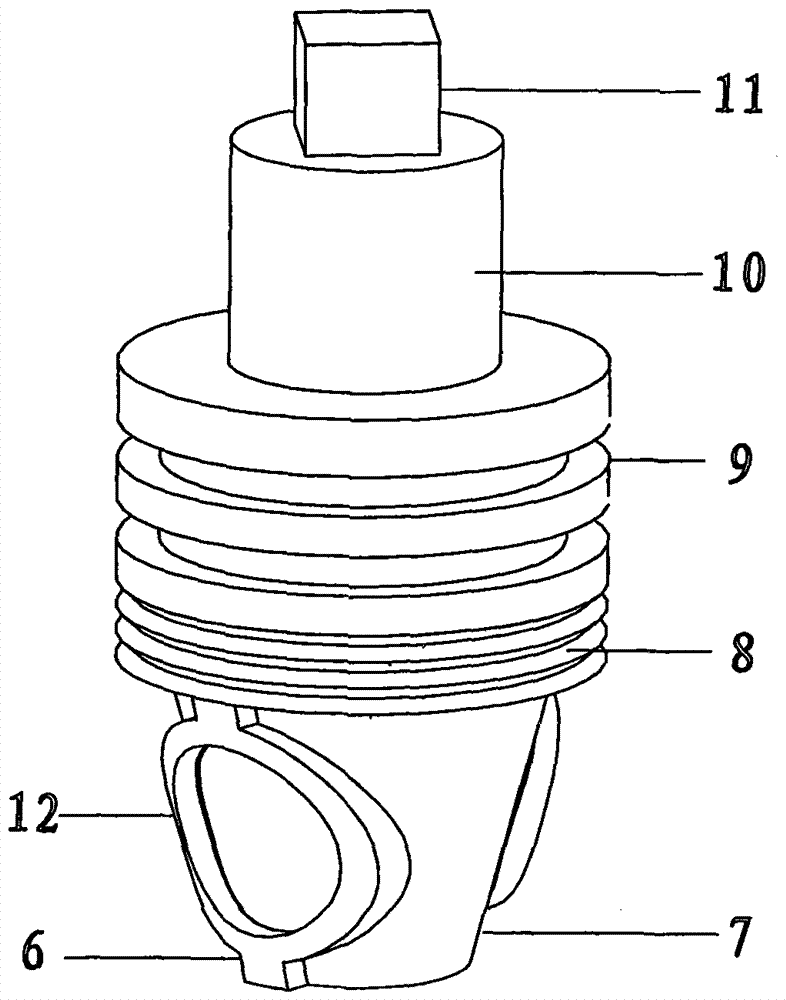

[0018] Second, the spool (2) is required to be put on a lathe first, and completed in one cut according to the size. Car pipe thread and two-layer annular groove (9) on the spool, according to the taper of the valve body cavity on the drawing, process the inverted truncated cone (7) of the spool, and then process the fluid passage hole (12). Finally, vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com