A high-safety horizontal explosion-proof tank door body and horizontal explosion-proof tank capable of realizing labyrinth sealing

A labyrinth-type sealing, high-safety technology, applied in the field of high-safety horizontal explosion-proof tank doors and horizontal explosion-proof tanks, can solve the problems of long opening and closing time, limited explosion-proof function, secondary injury to surrounding personnel, etc. The effect of the simple structure of the dental inlay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

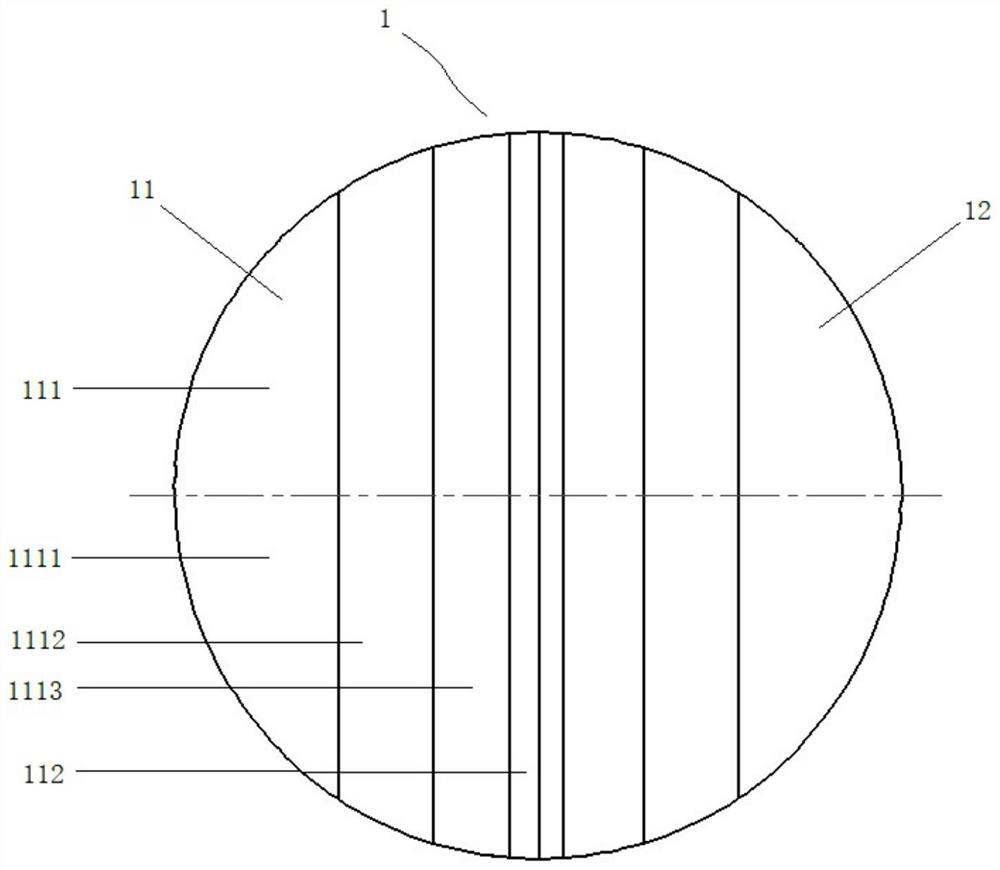

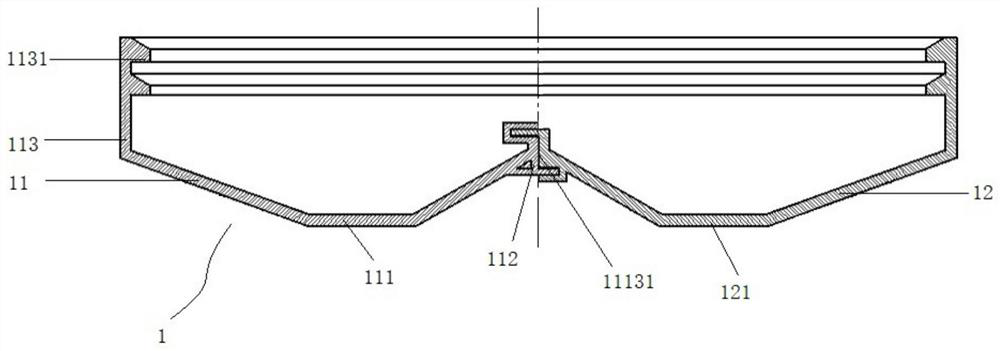

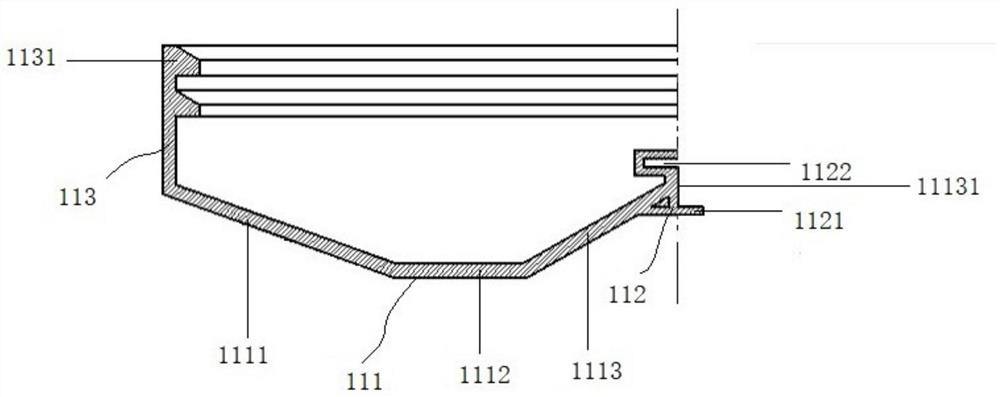

[0050] A high-safety horizontal explosion-proof tank door 1 capable of realizing a labyrinth seal, such as figure 1 As shown, it is a schematic diagram of the front view of the first embodiment of the high-safety horizontal explosion-proof tank door body 1 capable of realizing a labyrinth seal according to the present invention. The door body 1 includes a left door leaf 11 and a right The door leaf 12; the left door leaf 11 and the right door leaf 12 both include a door panel 111 and an inlay structure 112 arranged on the door panel, and the left door leaf 11 and the right door leaf 12 are relatively embedded by the respective inlay structures. The sleeve arrangement realizes the mutual fitting of the left door leaf 11 and the right door leaf 12. The inlay structure 112 is set at the position where the door panels are in contact (when the door body 1 is closed, the left door panel 111 and the right door panel 121 can contact) or close to it (when the door body 1 is closed, the...

Embodiment 2

[0061] As a preference, it is a schematic structural diagram of the second embodiment of the high-safety horizontal explosion-proof tank door 1 capable of realizing a labyrinth seal according to the present invention. The difference from the first embodiment is that the door panel 111 can be as follows Figure 4 The vertical plate shown.

Embodiment 3

[0063] As a preference, it is a schematic structural diagram of the third embodiment of the high-safety horizontal explosion-proof tank door 1 capable of realizing a labyrinth seal according to the present invention. The difference from the first embodiment is that the door panel 111 can be as follows Figure 5 Arched panels shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com