High-security horizontal explosion-proof tank door body and high-security horizontal explosion-proof tank

A high-safety, explosion-proof tank technology, used in blasting and other directions, can solve the problems of secondary injury to surrounding personnel, weakening shock wave leakage, and long opening and closing time, so as to improve safety, realize decompression and explosion relief, improve The effect of affordability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

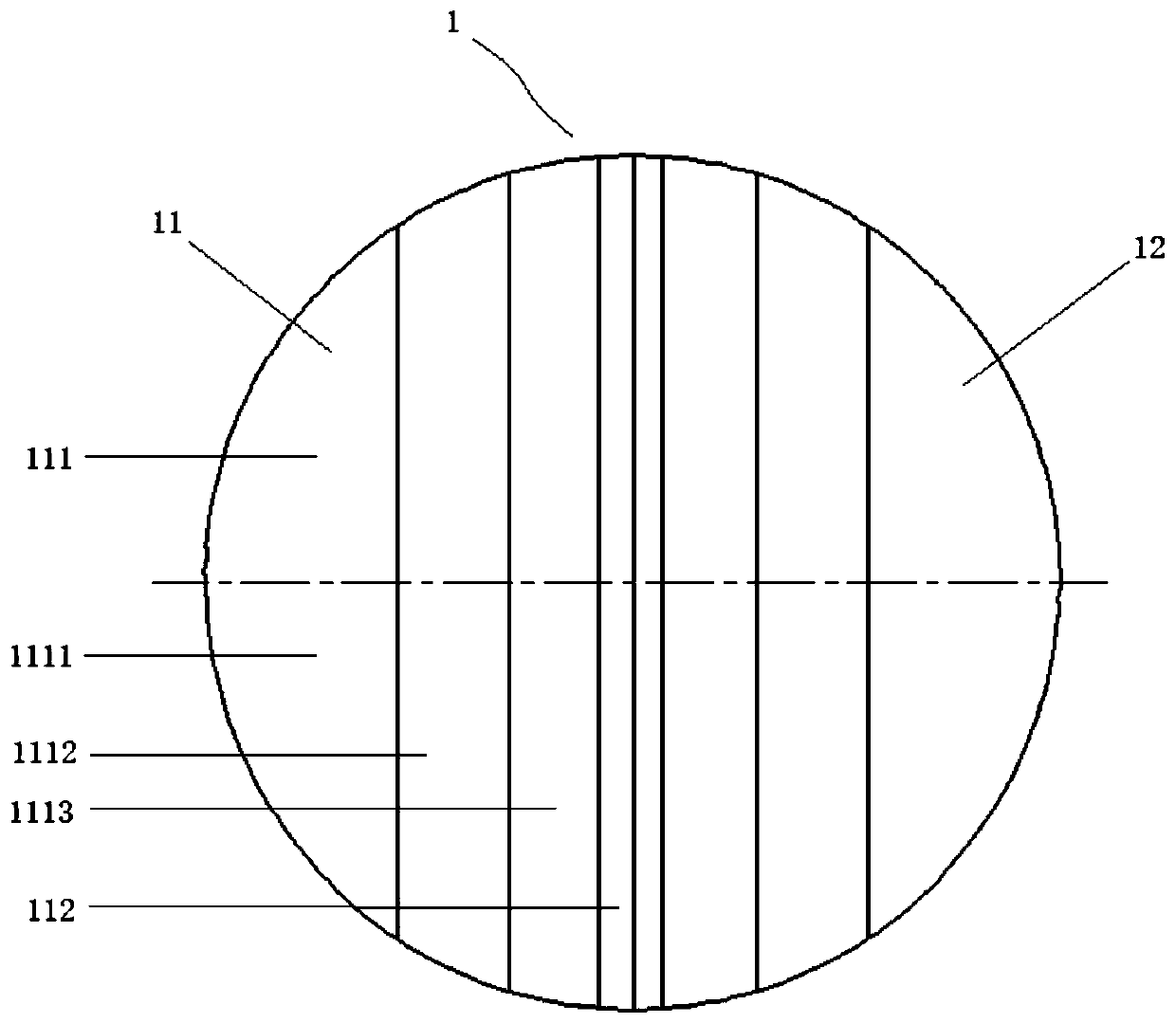

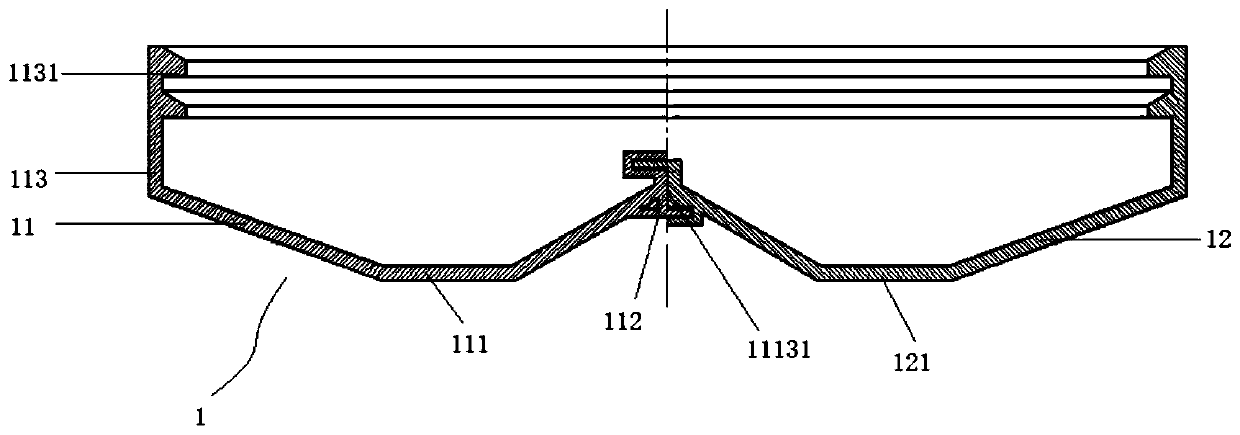

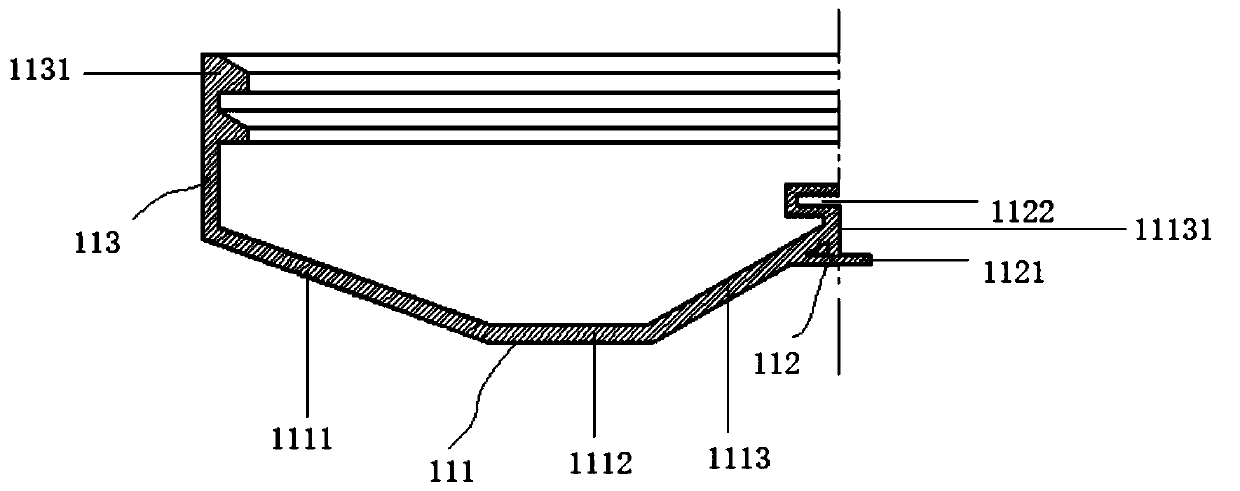

[0053] Such as Figure 1-3 As shown, it is a structural schematic diagram of the first embodiment of a high-safety explosion-proof tank door in the present invention. The high-safety explosion-proof tank door 1 includes a left door leaf 11 and a right door leaf 12 that are fitted together; the left door panel 111 and the right door panel 121 are arranged bilaterally symmetrically with the position where the middle side thereof is in contact with each other; A number of vertical plates connected end to end; among them, in the axial direction of the explosion-proof tank, the plate whose left edge is behind its right edge is a left-inclined plate, and the plate whose left edge is in front of its right edge is a right-inclined plate. The sum of the effective areas of all the left-sloping panels of the left door panel is less than or equal to the sum of the effective areas of all the right-sloping panels, and the sum of the effective areas of all the right-sloping panels of the rig...

Embodiment 2

[0063] When the explosive in the explosion-proof tank explodes, it will produce a circumferential impact force on the explosion-proof tank door 1 along the axis of the explosion-proof tank. The high-safety explosion-proof tank door 1 of the present invention, such as Figure 4As shown, it is a front view structural diagram of the second embodiment of the explosion-proof tank door 1 of the present invention. The difference from the embodiment is that, taking the left door panel as an example, the left door panel 111 is arranged along its radial direction and includes the first The three-stage flat plate structure of the annular plate 1111', the second annular plate 1112' and the third annular plate 1113', when the impact force of the explosion-proof tank door body 1 acts on the first annular plate 1111' and the third annular plate 1113' , there will be radial force components opposite in direction along the horizontal direction. The effective area of the first annular plate 1...

Embodiment 3

[0065] As preferred, such as Figure 5 As shown, it is a schematic front view structure diagram of the closed state of the third embodiment of the high-safety explosion-proof tank door 1 according to the present invention. The high-safety horizontal explosion-proof tank door 1 includes left door leaves that are fitted together. 11 and right door leaf 12. Different from the first embodiment, the high-safety horizontal explosion-proof tank door 1 described in this embodiment also includes a horizontal limit slip mechanism 14, and the horizontal limit slip mechanism 14 includes a The horizontal limit sliding track 141 on the upper side and the lower side of the tank body 2 and the matching horizontal limit sliding block 142; The horizontal sliding blocks 142 are respectively provided at the positions of the side and / or the lower side relative to the horizontal limit sliding track 141 .

[0066] Preferably, the horizontal limit sliding block 142 is a triangular reinforcing rib p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com