Pneumatic baffle valve for aseptic steam freeze dryer

A flapper valve, freeze dryer technology, applied in the direction of drying, valve lift, valve details, etc., can solve the problem that the service life of manual ball valve or pneumatic ball valve is not long, can not meet the requirements of perfect appearance design, increase steam aseptic freeze-drying The machine risk coefficient and other issues can be improved to achieve the effect of improving the degree of automation control, reliable performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

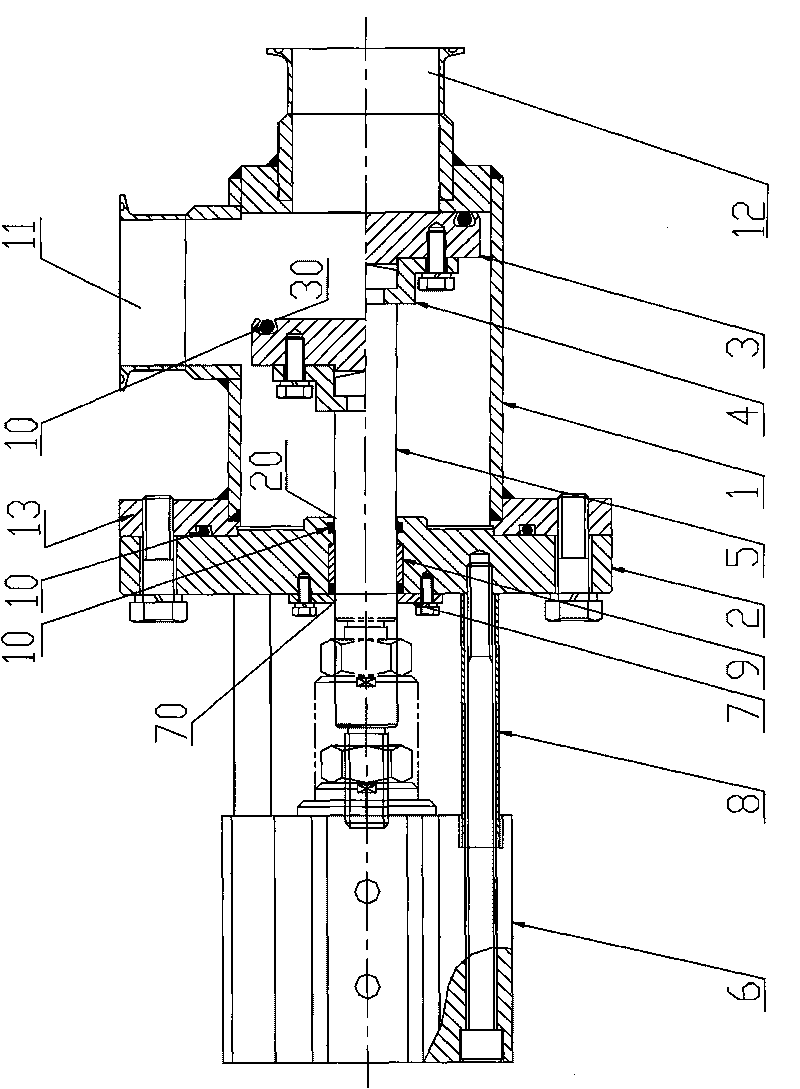

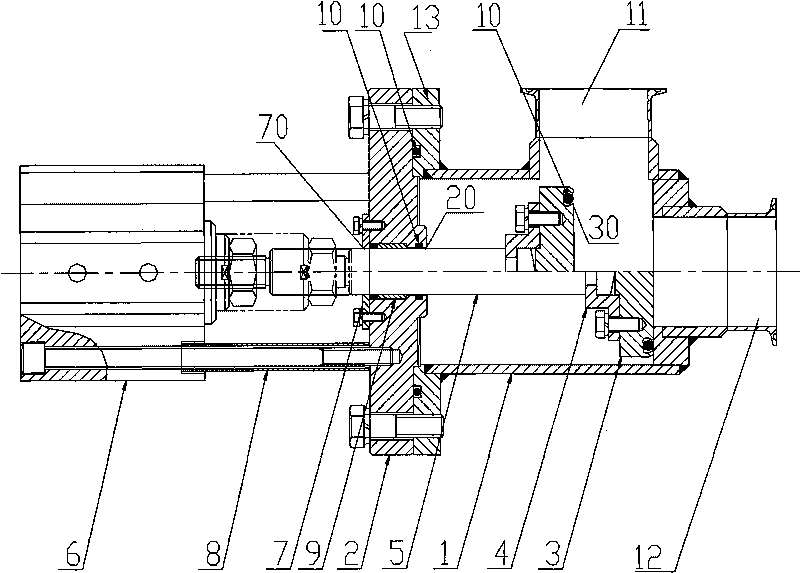

[0020] Such as figure 1 As shown, the present invention is a pneumatic flapper valve for a steam aseptic freeze dryer, which includes an actuator 6, a valve cover 2, a valve stem 5, a valve body 1, and a valve plate 3 arranged in the inner cavity of the valve body 1 and a coupling 4, wherein the coupling 4 is fixedly connected to one end surface of the valve plate 3 by bolts;

[0021] The valve body 1 is provided with a first outlet 11 and a second outlet 12, and the first outlet 11 and the second outlet 12 are perpendicular to each other; the first outlet 11 of the valve body 1 is connected with the condenser pipeline of the freeze dryer (not shown in the figure). Shown), the second outlet 12 is connected to the vacuum pump pipeline of the freeze dryer (not shown in the figure).

[0022] The bonnet 2 is connected with the flange 13 at the front end of the valve body 1 through bolts, and a through hole 20 is opened at the center of the end face of the bonnet 2, and a bushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com