Oil immersed power transformer conservator support assembling and welding device and welding method thereof

A technology for power transformers and oil storage tanks, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., and can solve the problem of inability to ensure the positioning size and verticality of the fixing plate of the foot of the oil storage tank and the fixing plate of the side wall of the oil tank, and large errors , It is difficult to guarantee the accuracy and other issues, to achieve the effect of small welding deformation, eliminating welding deformation, and high degree of generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

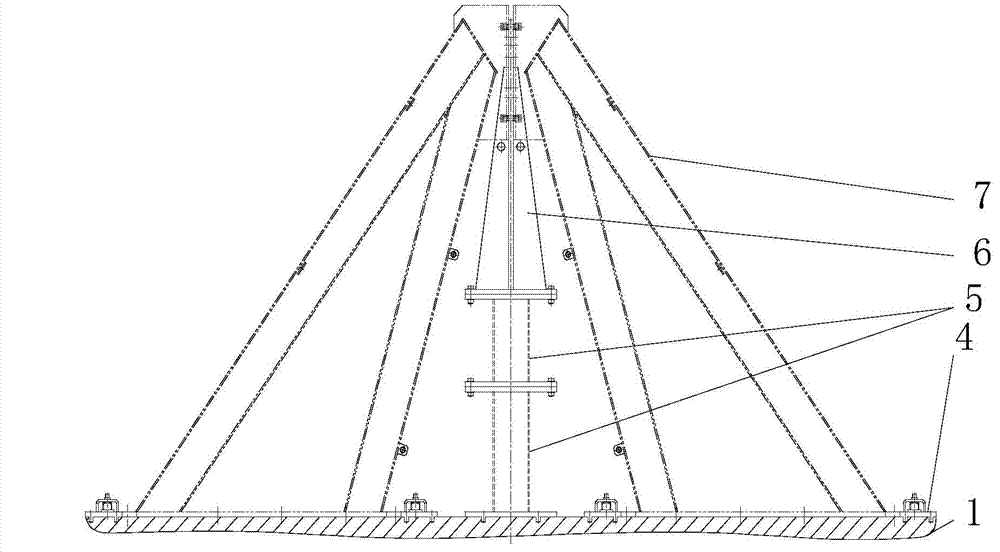

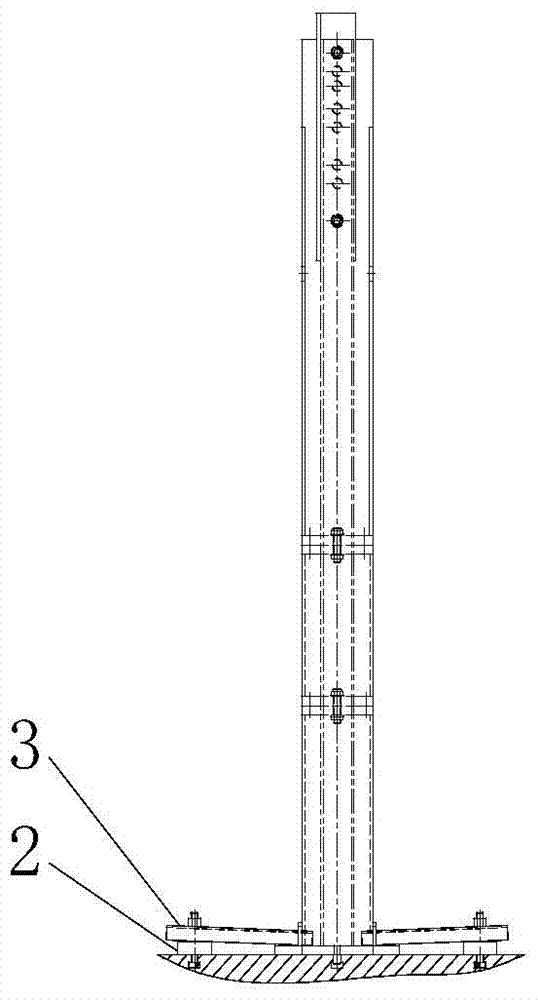

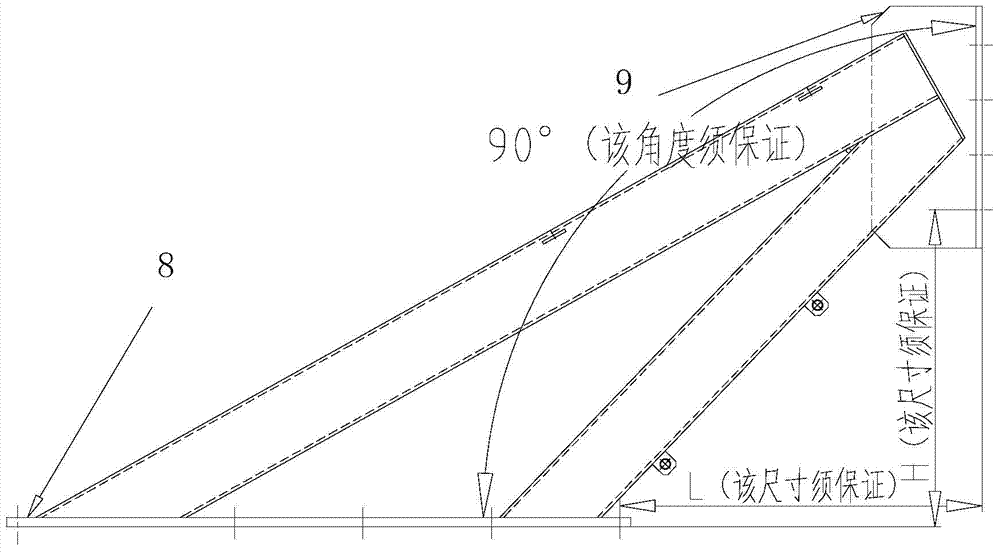

[0036] An oil-immersed power transformer oil conservator bracket assembly welding device, used to realize the welding operation between the oil conservator bracket, the oil conservator foot fixing plate, and the oil tank side wall fixing plate, such as figure 1 , 2 As shown, including welding platform, backing plate, pressure plate, horizontal positioning plate, riser block and vertical positioning plate,

[0037] The welding platform is a rectangular platform with four T-shaped grooves in the length direction, which are used to carry the oil conservator bracket, the side wall fixing plate of the oil tank and other components of the assembly welding device, and keep them in the welding process. stability;

[0038] The backing plate is a square with a through hole in the center, and is located between the pressing plate and the welding platform, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com