A device and method for measuring the dimension of a subgrade cavity

A measurement method, hollow technology, applied in the field of infrastructure construction, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

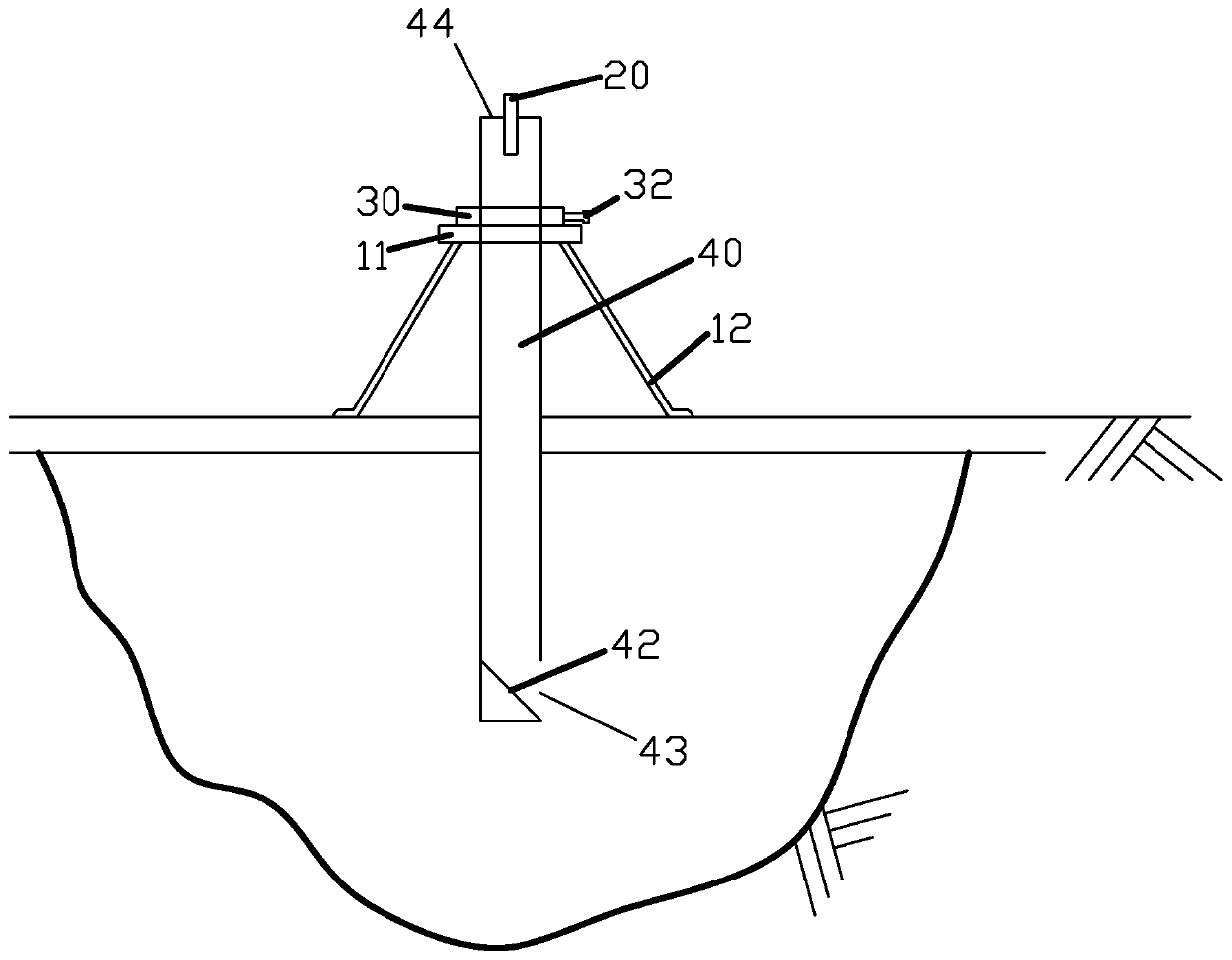

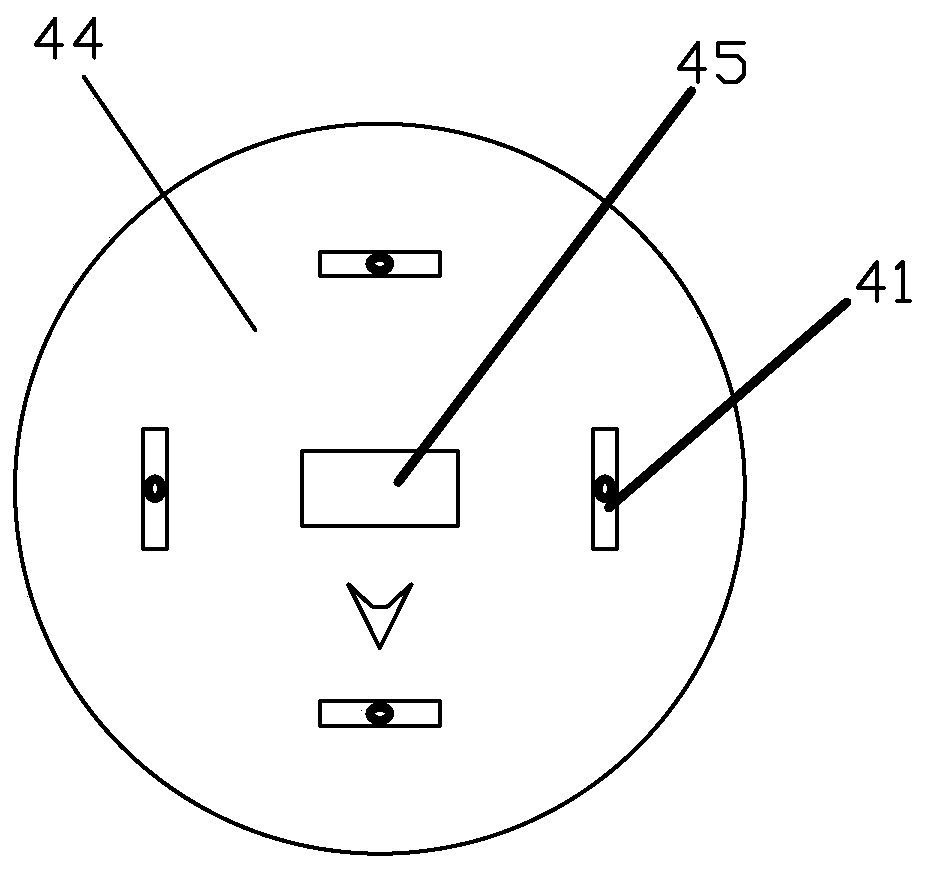

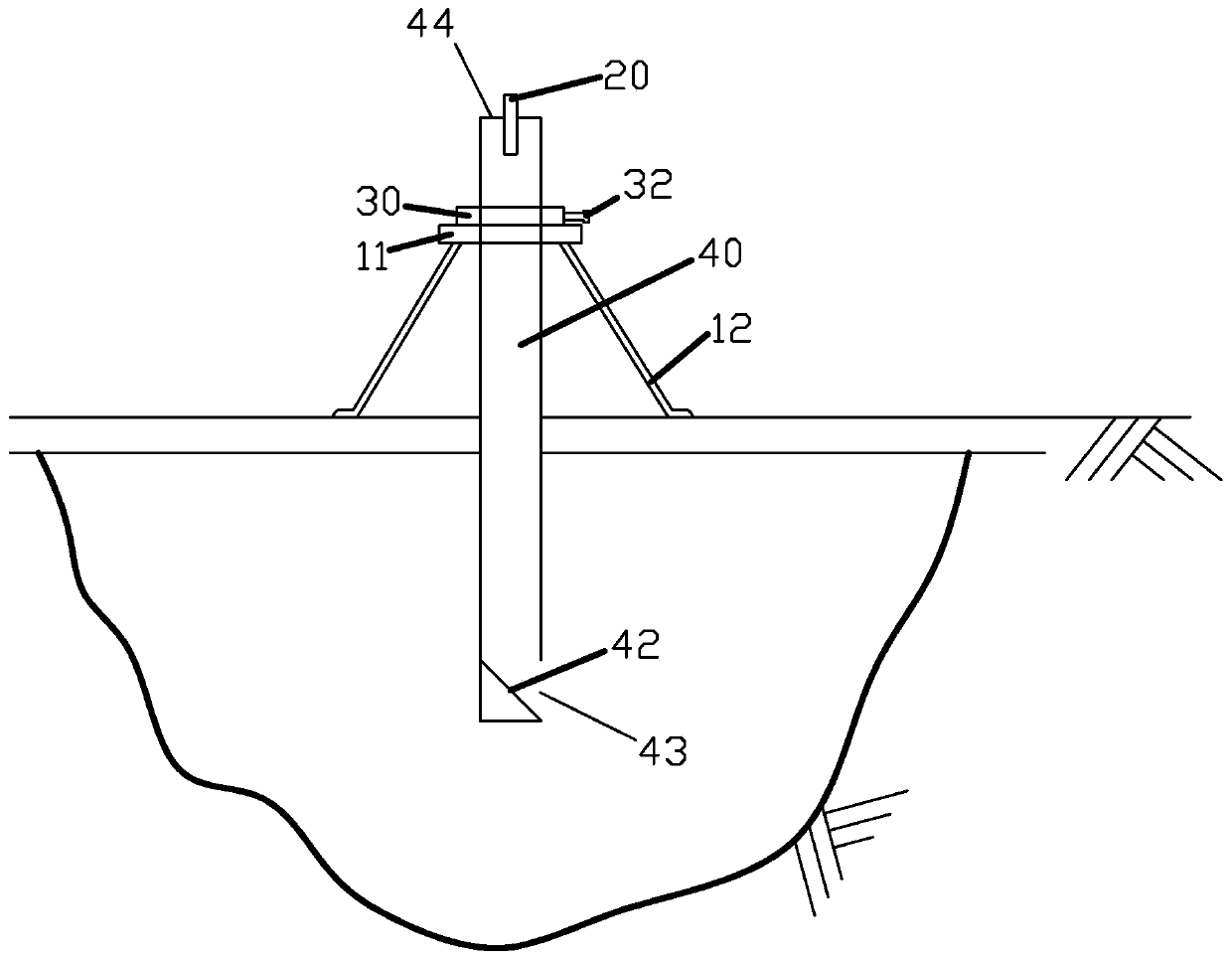

[0011] Please refer to figure 1 and figure 2 , a roadbed cavity size measuring device of the present invention includes a bracket, a laser range finder 20, a rotating disk 30 and a vertical tube 40, the bracket includes a horizontal disk 11 and a plurality of supporting feet 12 for supporting the horizontal disk, the The rotating disc 30 is rotatably arranged on the upper surface of the horizontal disc 11, and the horizontal disc 11 and the rotating disc 30 are respectively provided with relief holes corresponding to the vertical tube 40, and the vertical tube 40 can vertically pass through the rotary disc 30 in a vertically movable manner. and horizontal pan 11. The vertical cylinder 40 and the rotating disk 30 are clamped in the circumferential direction, and the two can rotate synchronously. The side wall of the rotating disk 30 is provided with a clamping piece 32 for limiting the movement of the vertical cylinder 40 in the vertical direction. When the clamping piece 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com