Double-lifting point embedded bulkhead gate system and application thereof

A flat gate and mosaic technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of inflexible opening and closing of automatic gates and long opening and closing time, so as to improve the opening and closing adjustment efficiency and shorten the opening and closing time , easy to control the effect of water level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

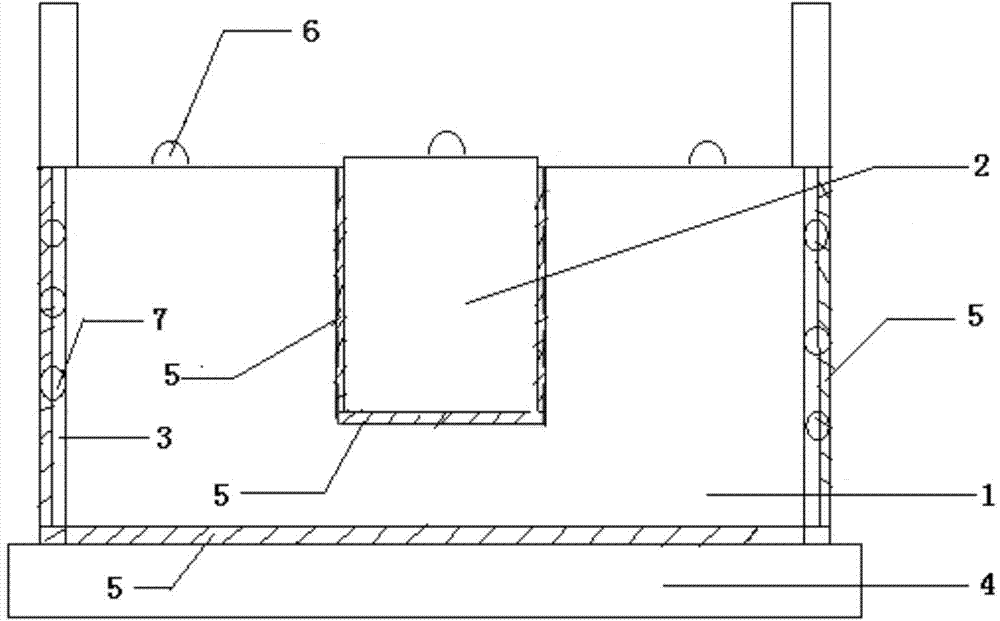

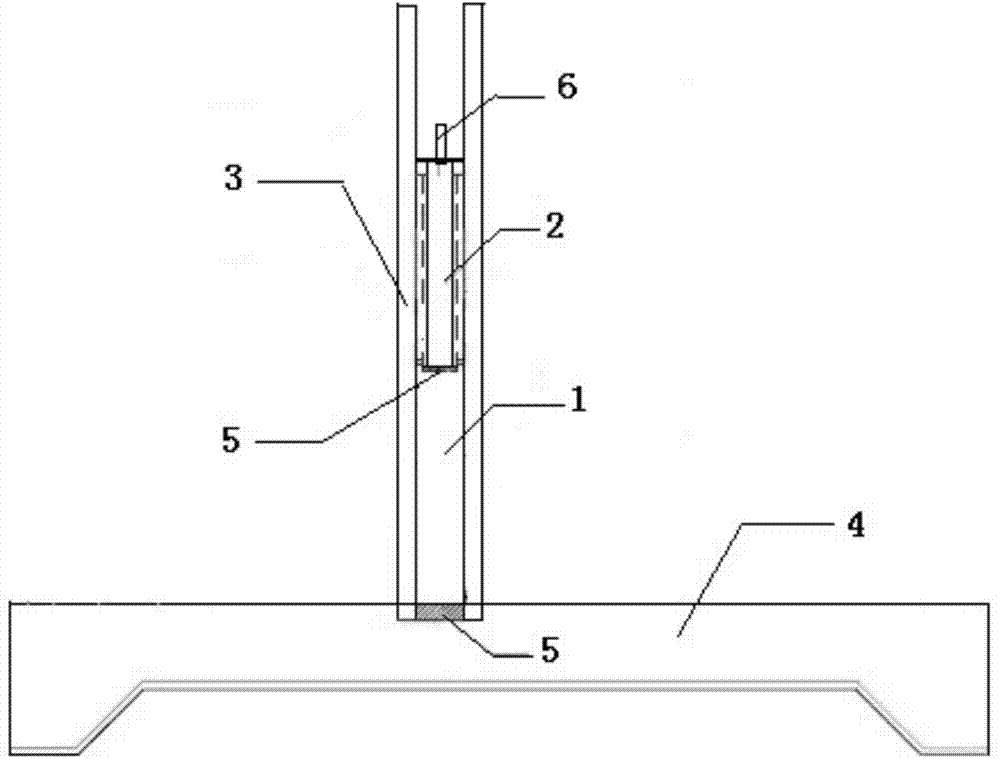

[0028] Double hanging point mosaic type flat gate system, including large flat gate 1, small flat gate 2, gate frame 3, gate bottom plate 4, water-stop rubber 5 and lifting lug 6; the gate frame 3 is a square frame with an upper end opening and Fixedly arranged on the gate base plate 4, the large flat gate 1 is a square plate, the large flat gate 1 is arranged in the gate frame 3 and can move up and down in the vertical direction in the gate frame 3, the inner wall of the gate frame 3 Water-stop rubber 5 is arranged in the center, and the upper end of the large flat gate 1 is provided with a square gap, and the small flat gate 2 is a square plate suitable for the square gap, and the small flat gate 2 is embedded in the large flat gate 1. Inside the square gap and capable of moving up and down in the vertical direction, the inner wall of the square gap of the large flat gate 1 is provided with a water-stop rubber 5 , and the upper ends of the square gap of the large flat gate 1 ...

Embodiment 2

[0031] The difference between the double suspension point mosaic type slab gate system as described in Embodiment 1 is that each side wall of the gate frame 3 is provided with 8 sliding balls 7 evenly and movablely.

[0032] In this embodiment, the advantage of being provided with the rolling ball 7 is mainly that when the large flat gate 1 is opened and closed, the sliding friction is changed into rolling friction, which not only saves energy consumption, but also reduces the friction loss of the large flat gate 1 and prolongs the working life of the large flat gate 1. service life.

Embodiment 3

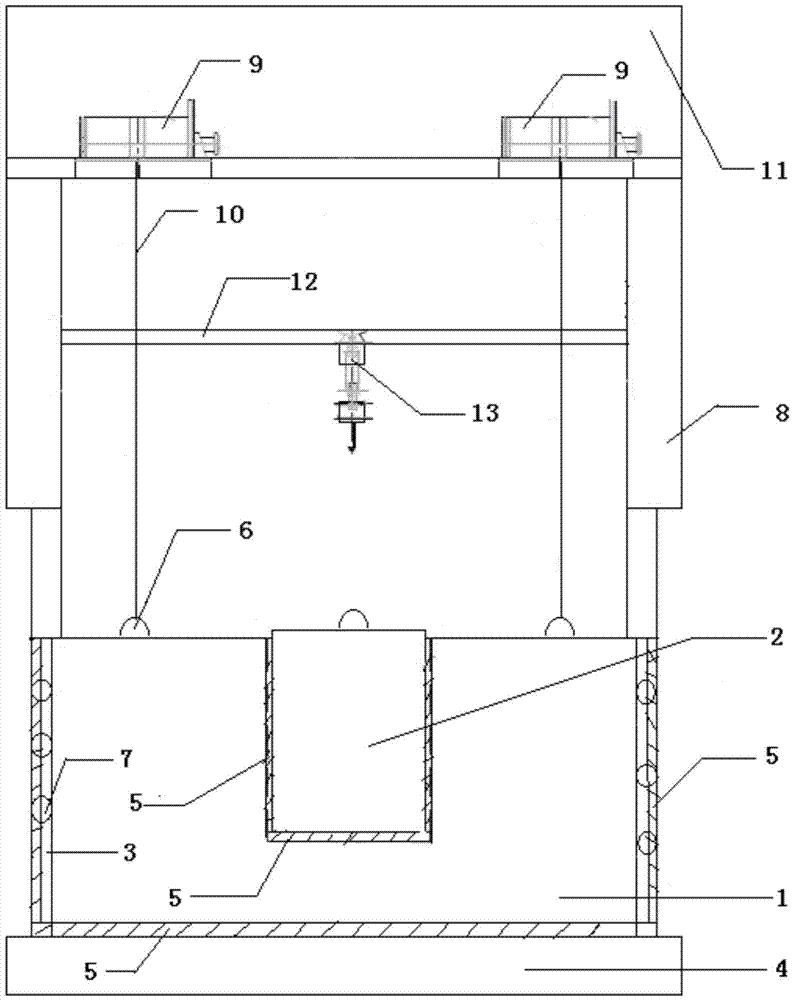

[0034] The double suspension point mosaic type slab gate system as described in Embodiment 1, the difference is that the double suspension point mosaic type slab gate system also includes a frame bridge 8, a gate hoist 9, a rope 10, and a gate hoist room 11 , guide rail 12 and electric hoist 13; the gate frame 3 is a square frame with an upper end opening and is fixedly arranged on the gate base plate 4, the large flat gate 1 is a square plate, and the large flat gate 1 is arranged in the gate frame 3 And can move up and down in the vertical direction in the gate frame 3, the inner wall of the gate frame 3 is provided with a water-stop rubber 5, the upper end of the large flat gate 1 is provided with a square gap, and the small flat gate 2 It is a square plate with the same size as the square notch. The small flat gate 2 is embedded in the square notch of the large flat gate 1 and can move up and down in the vertical direction. The inner wall of the square notch of the large fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com