Horizontal type vulcanizing tank with vertical doubly-opened door panels being opened and closed in lifting mode

A technology for opening and closing the door cover and vulcanization tank, which is applied in door/window fittings, wing leaf arrangement, wing leaf components, etc., can solve problems such as poor safety, short service life of seals, and poor sealing of sealed doors. To achieve the effect of short opening and closing time, high-end product, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be further described with reference to the drawings and the embodiments.

[0016] The vulcanizing tank of the present invention is used for vulcanizing rubber products. When in use, the rubber products are loaded by the trolley and pushed into the vulcanization tank from one side, and then the vulcanization tank is sealed, and the rubber products are vulcanized under the action of 200 ℃ steam and a certain pressure. After vulcanization for a period of time, from the other side of the vulcanization tank Push side out to complete the vulcanization process.

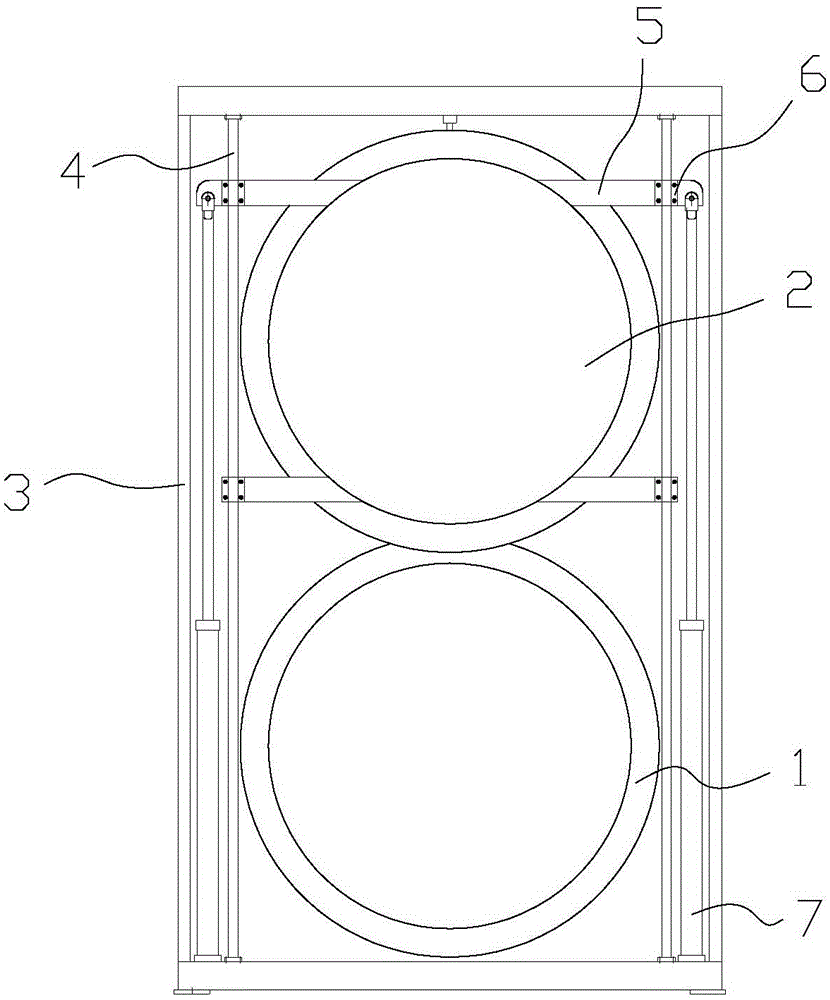

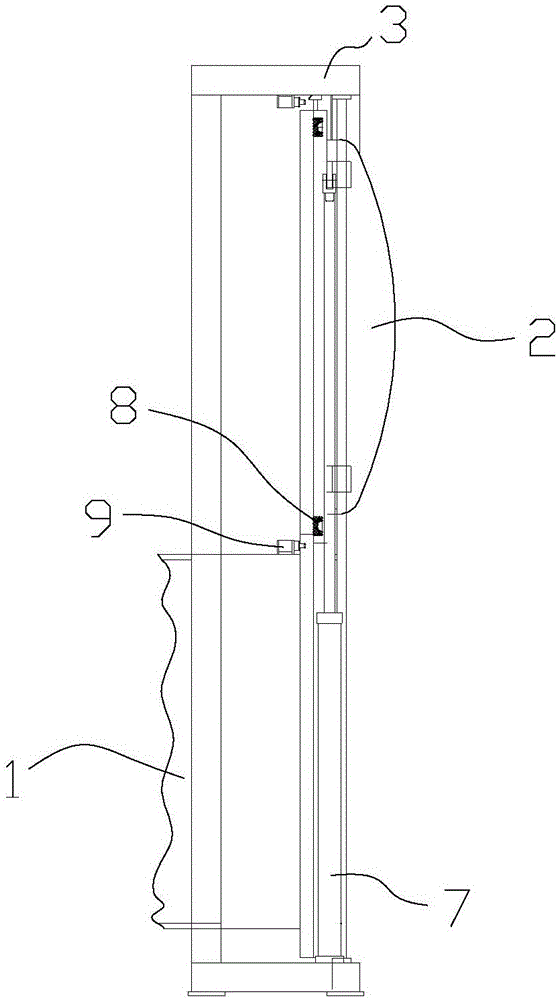

[0017] Such as figure 1 with figure 2 As shown, the vulcanizing tank mainly includes a cylinder body 1 and door covers 2 provided at both ends of the cylinder body 1, and the shape of the door cover 2 matches the opening of the cylinder body 1. The cylinder 1 is placed horizontally, and its overall shape is generally cylindrical. The two ends of the cylinder 1 are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com