Large workpiece heating furnace

A technology for large workpieces and heating furnaces, which is applied in electric furnace heating, maintenance of heating chambers, lighting and heating equipment, etc. It can solve the problems of uneven heating temperature and large temperature difference of workpieces, and achieve high workpiece yield and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

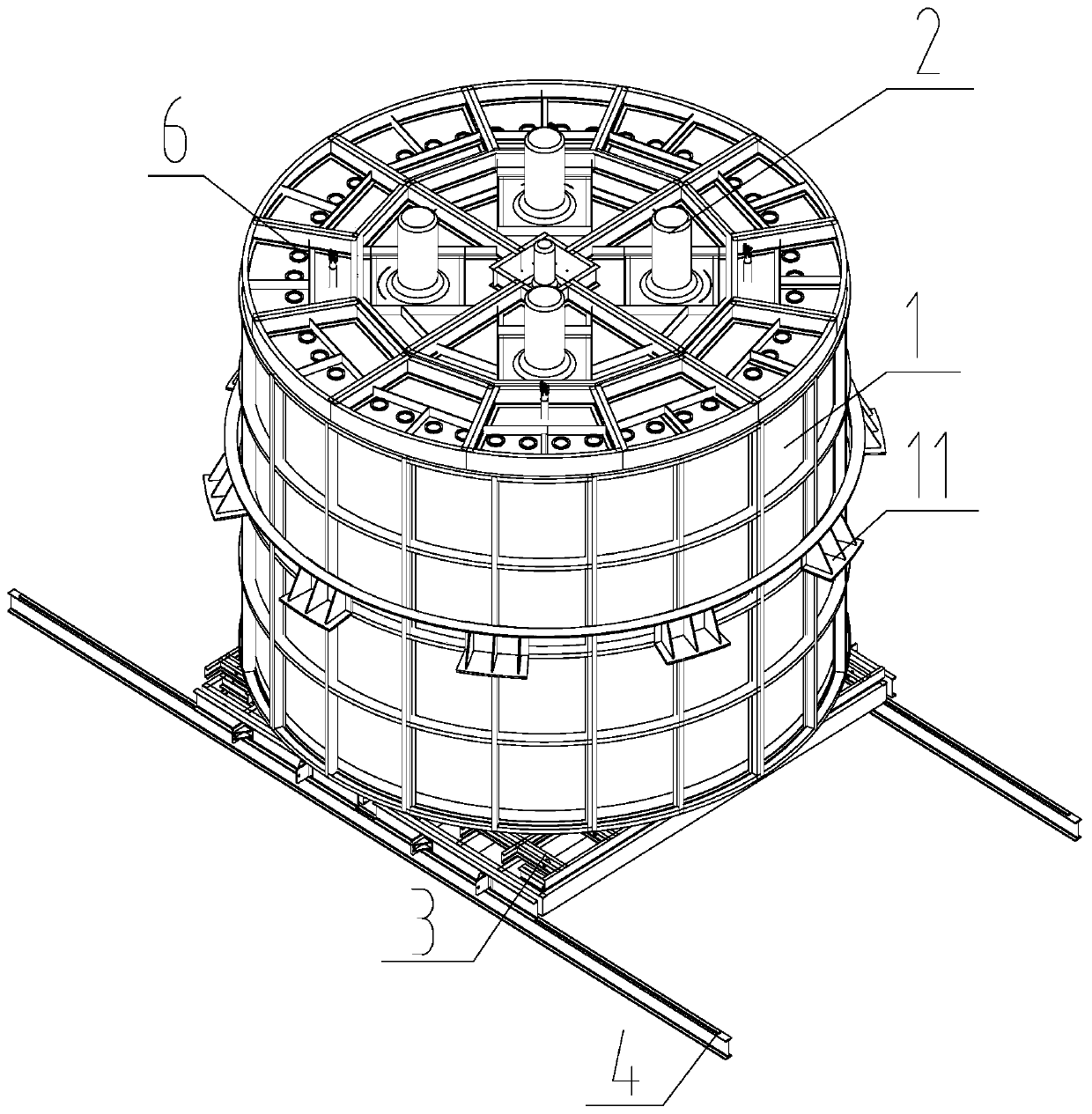

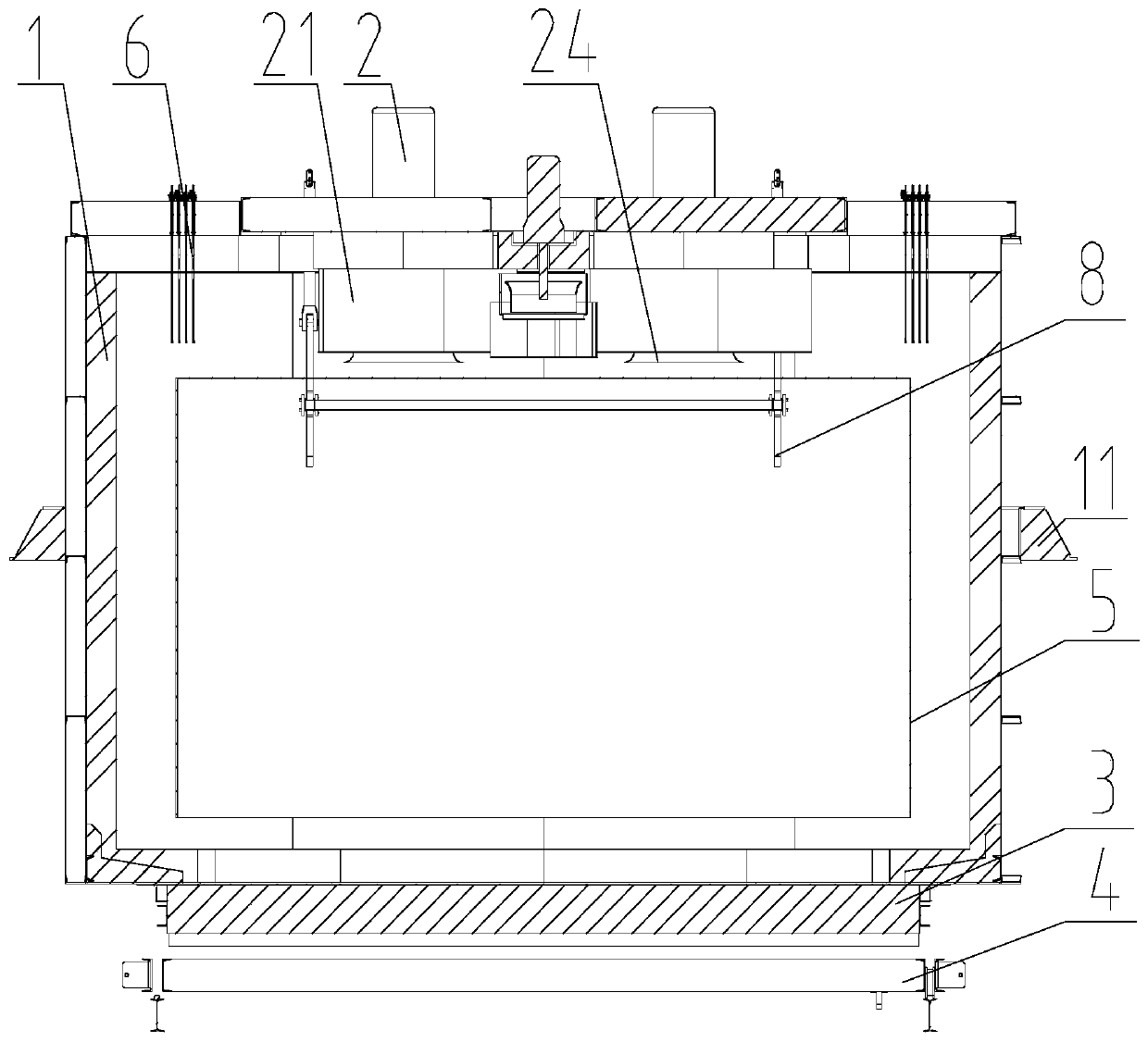

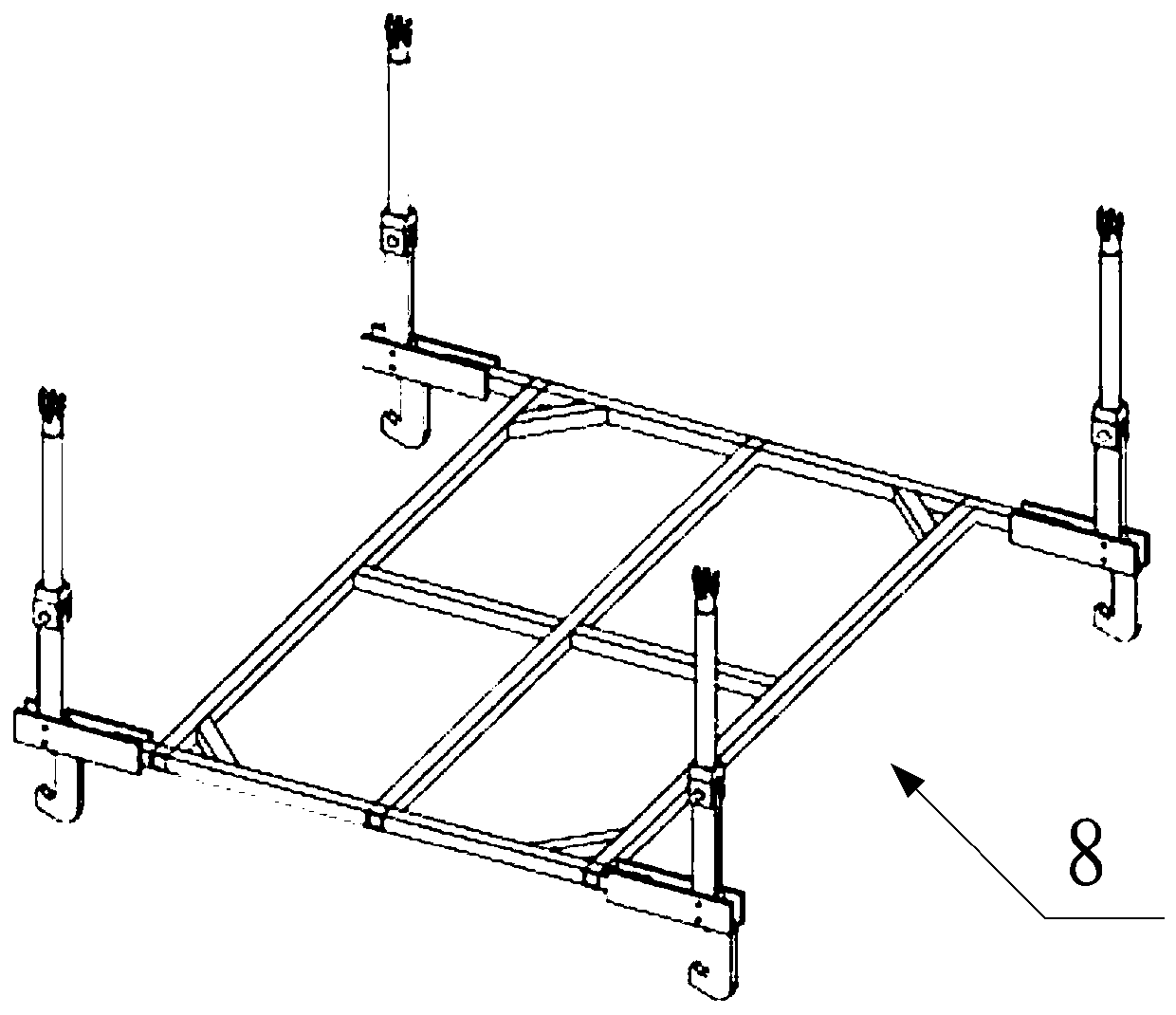

[0033] Such as figure 1 , 2 The shown heating furnace is used for heat treatment of large aluminum alloy rings, which includes a cylindrical furnace body 1, the furnace body 1 includes a furnace roof and a furnace door assembly arranged at the furnace bottom;

[0034] The furnace body 1 includes the furnace shell and insulation materials. The furnace shell is a cylindrical structure welded by steel plate and section steel. The furnace lining is a high-purity refractory fiber module, which reduces the heat loss during the working process of the heating furnace and ensures the temperature of the furnace body.

[0035] The furnace door assembly 3 and the furnace door moving track 4 are arranged at the bottom of the furnace body 1, and the furnace door assembly 3 includes a furnace door that splits in two, and a furnace door opening and closing structure that controls the opening and closing of the furnace door. During work, the furnace door opening and closing structure control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com