Turbocharging electric control bypass valve design

A turbocharger and turbocharger technology, applied in valve details, valve devices, mechanical equipment, etc., can solve problems such as vibration noise, reduced reliability life, system wear, etc., to reduce frequency, increase reliability and life. , the effect of reducing output torque and power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

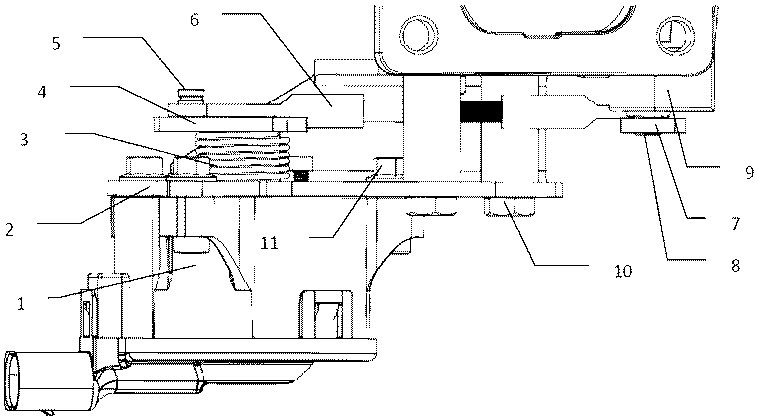

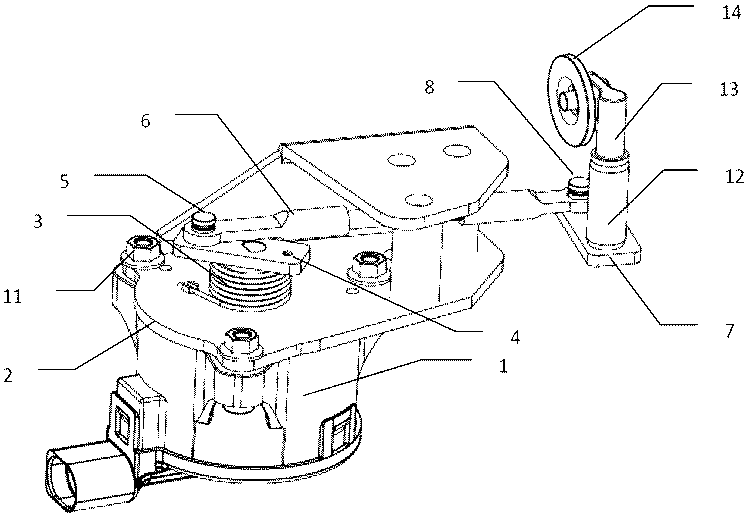

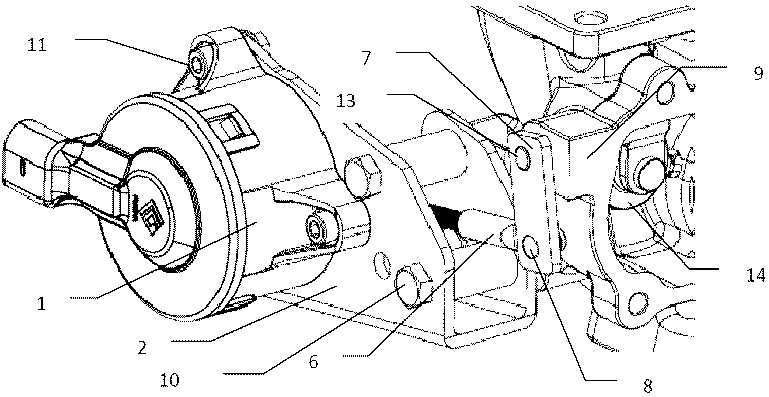

[0028] figure 1 It is a structural perspective view of a turbocharger bypass valve with a preloaded spring in a preferred embodiment of the present invention. This embodiment is as follows: the actuator installation and fixing plate 2 is fixed to the turbine casing 9 through a plurality of bolts 10 , and the brushless torque actuator 1 is fixed to the actuator installation and fixing plate 2 through a plurality of bolts 11 . The output shaft of the actuator is fixedly connected with the rocker arm 4 on the driving side. Fixed connection methods such as welding, riveting, etc. are usually used. A spring 3 is installed between the driving side rocker arm 4 and the actuator mounting plate 2 . The spring is preloaded by rotation before installation. The driving side rocker arm 4 is connected with the connecting rod 6 movable mechanism through the driving side pivot pin 5 . Its connection method can be common shaft pin, also can be various bearing sleeves, in order to reduce fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com