A new type of energy-saving tamping coke oven coal feeding device

A technology for tamping coke ovens and feeding coal, which is applied to coke ovens, charging devices, and charging/unloading combined devices, etc. The problem of poor transmission stability and supporting the coal bottom plate is achieved to avoid long transmission links, simple and convenient lubrication and maintenance, and convenient and fast transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

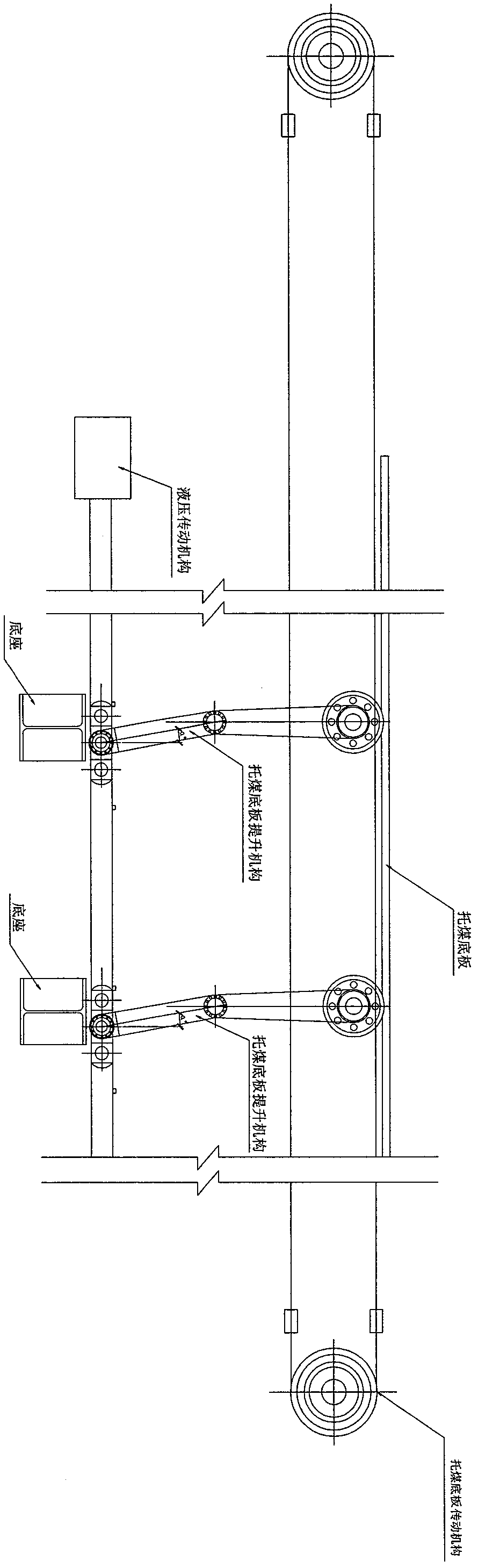

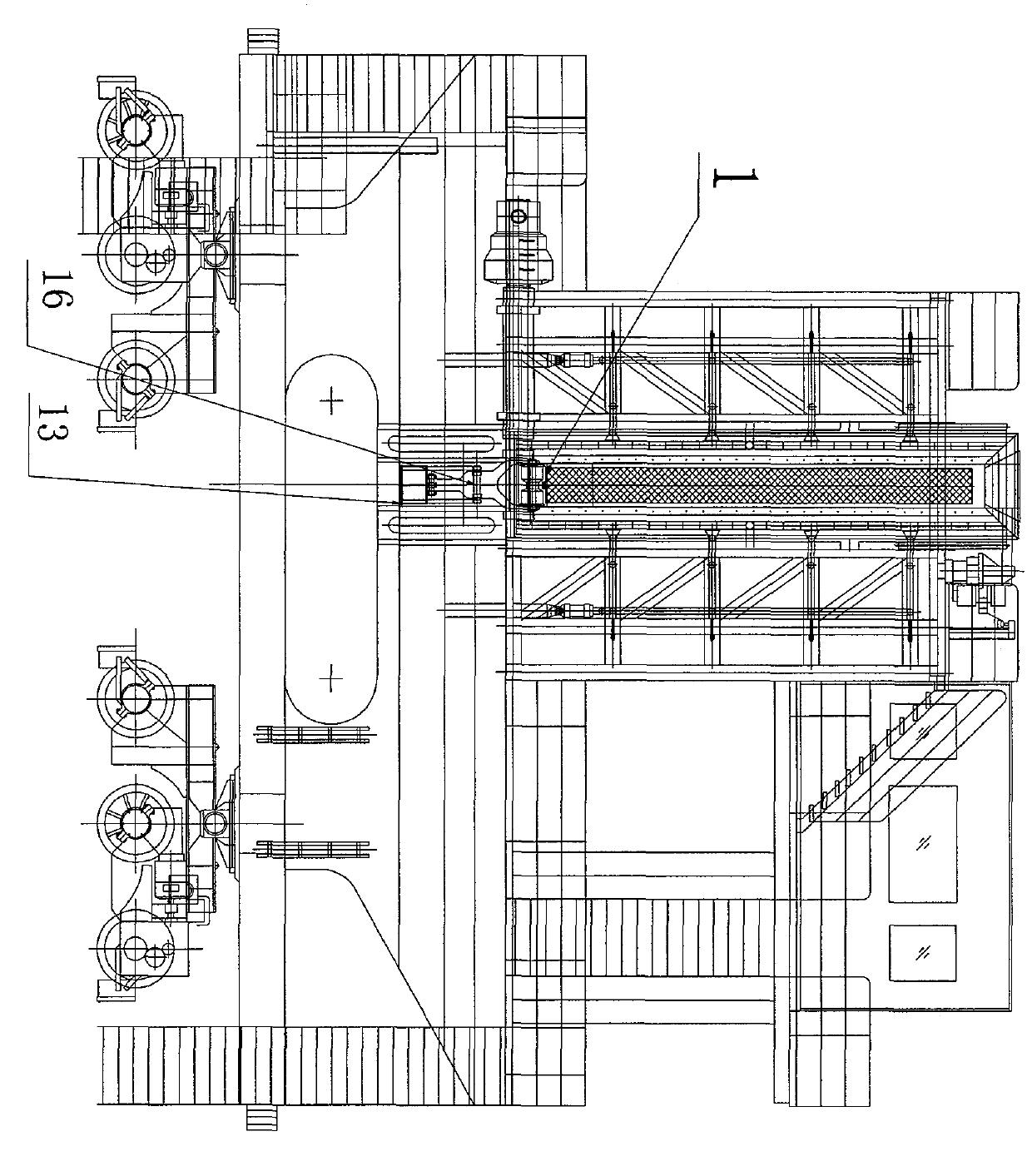

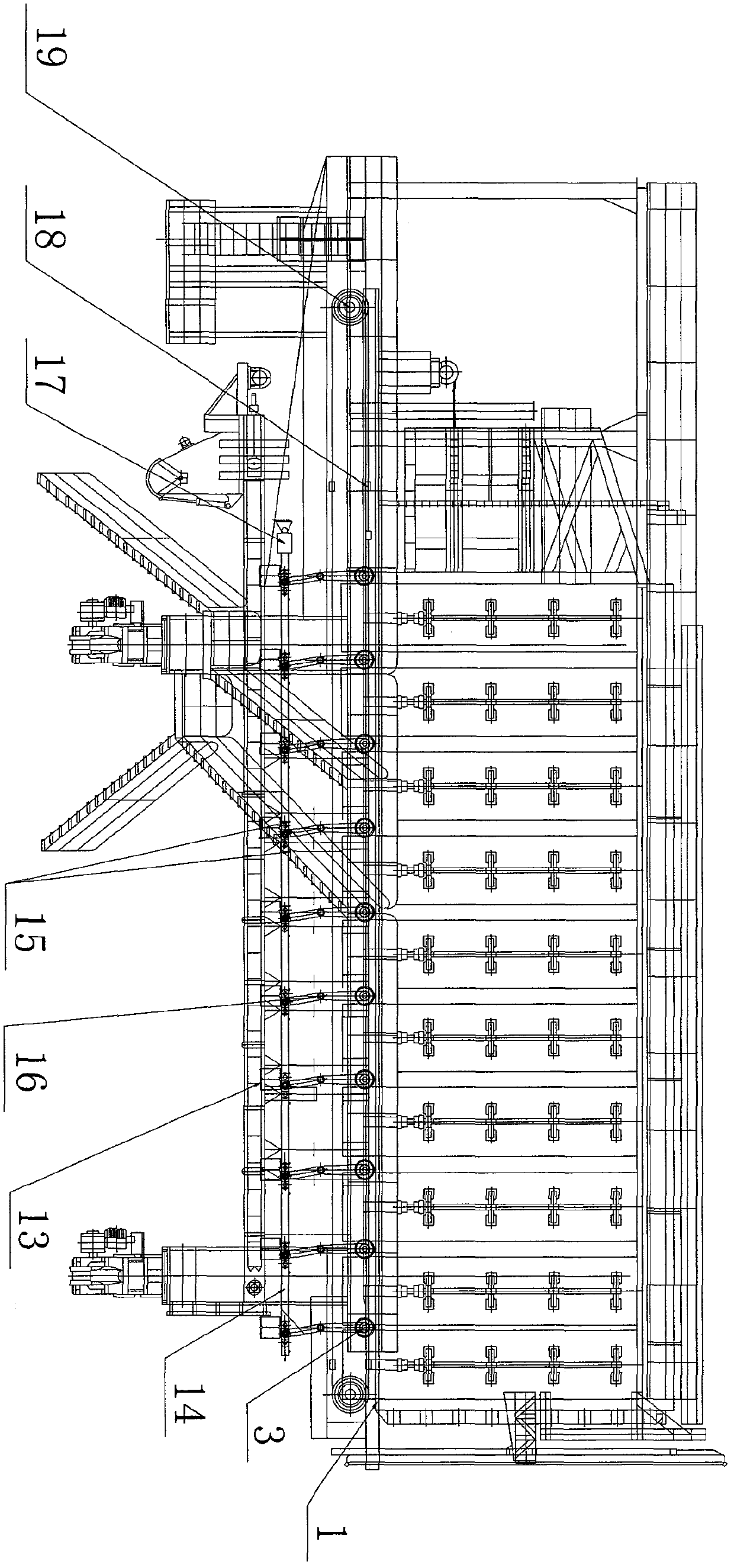

[0010] The new energy-saving tamping coke oven coal feeding device is composed of a coal bottom plate jacking mechanism, a hydraulic transmission mechanism, a wire rope dragging mechanism, a limit mechanism and a base. The lifting mechanism of the coal-supporting floor is connected with the hydraulic transmission mechanism, and the horizontal thrust output by the hydraulic transmission mechanism is transmitted to the lifting mechanism of the coal-supporting floor to drive the deflection of the special-shaped integral support rod to drive the support roller to move up or down; the transmission mechanism of the coal-supporting floor and the The coal-supporting bottom plate is connected, and the transmission mechanism of the coal-supporting bottom plate drives the coal-supporting bottom plate to move horizontally back and forth in the support roller groove; the limit mechanism is connected with the hydraulic transmission mechanism, and when the hydraulic transmission rod moves hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com