Torque calibration testing device for angular travel electric actuator

A technology of electric actuator and testing device, which is applied in the direction of measuring device, testing of machine/structural components, testing of mechanical components, etc., can solve the problems of cumbersome operation, time-consuming and laborious, etc., and achieve the effect of improving testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

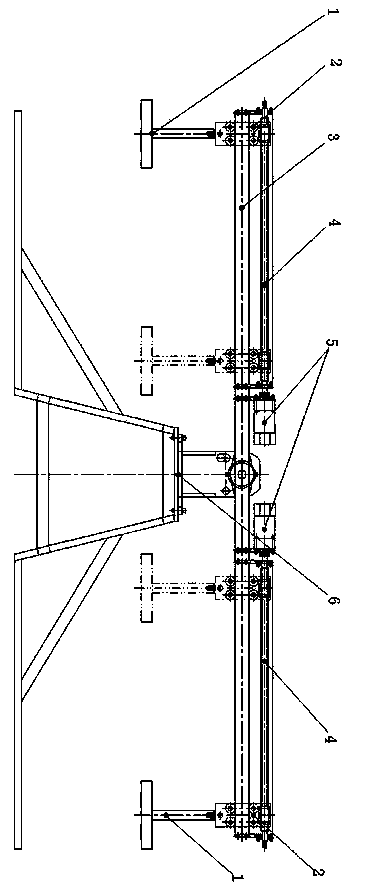

[0011] This embodiment is a torque calibration test device for angular stroke electric actuators, which includes: weight (1), pulley mechanism (2), force arm (3), lead screw (4), motor (5), and integral support (6), such as figure 1 As shown, the test device is left-right symmetrical, and is equipped with two motors (5), two lead screws (4), two pulley mechanisms (2), and two weights (1); the overall support (6) Connected with the force arm (3), the middle position of the force arm (3) is provided with a drive hole and the scale value is set on the force arm (3), wherein the electric actuator is connected to the force arm through the transfer drive sleeve (3) The drive hole in the middle is connected, the screw (4) and the motor (5) are fixed on the arm (3) through the integral bracket (6), and the arm (3) can be Rotate around the center of the overall support (6), the minimum rotation angle is 0°, the maximum is 105°, one end of the pulley mechanism (2) is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com