Synchronization equipment of ring-shaped crane double trolley

A synchronizing device, crane technology, applied in cranes, traveling bridge cranes, transportation and packaging, etc., can solve the problems of asynchronous and reduce the running drive mechanism, so as to reduce the product cost, reduce the running drive mechanism, and solve the asynchronous problem. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

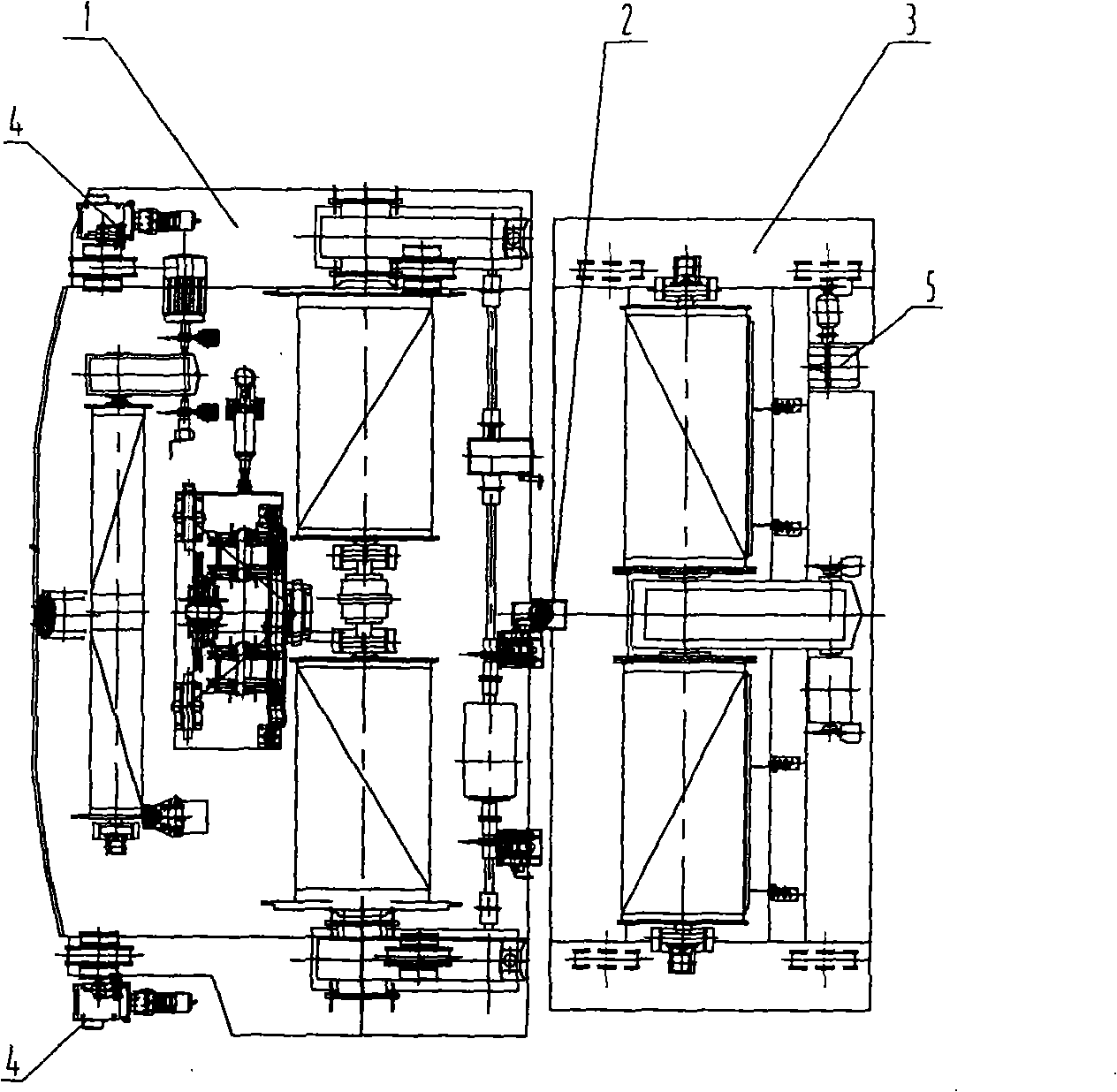

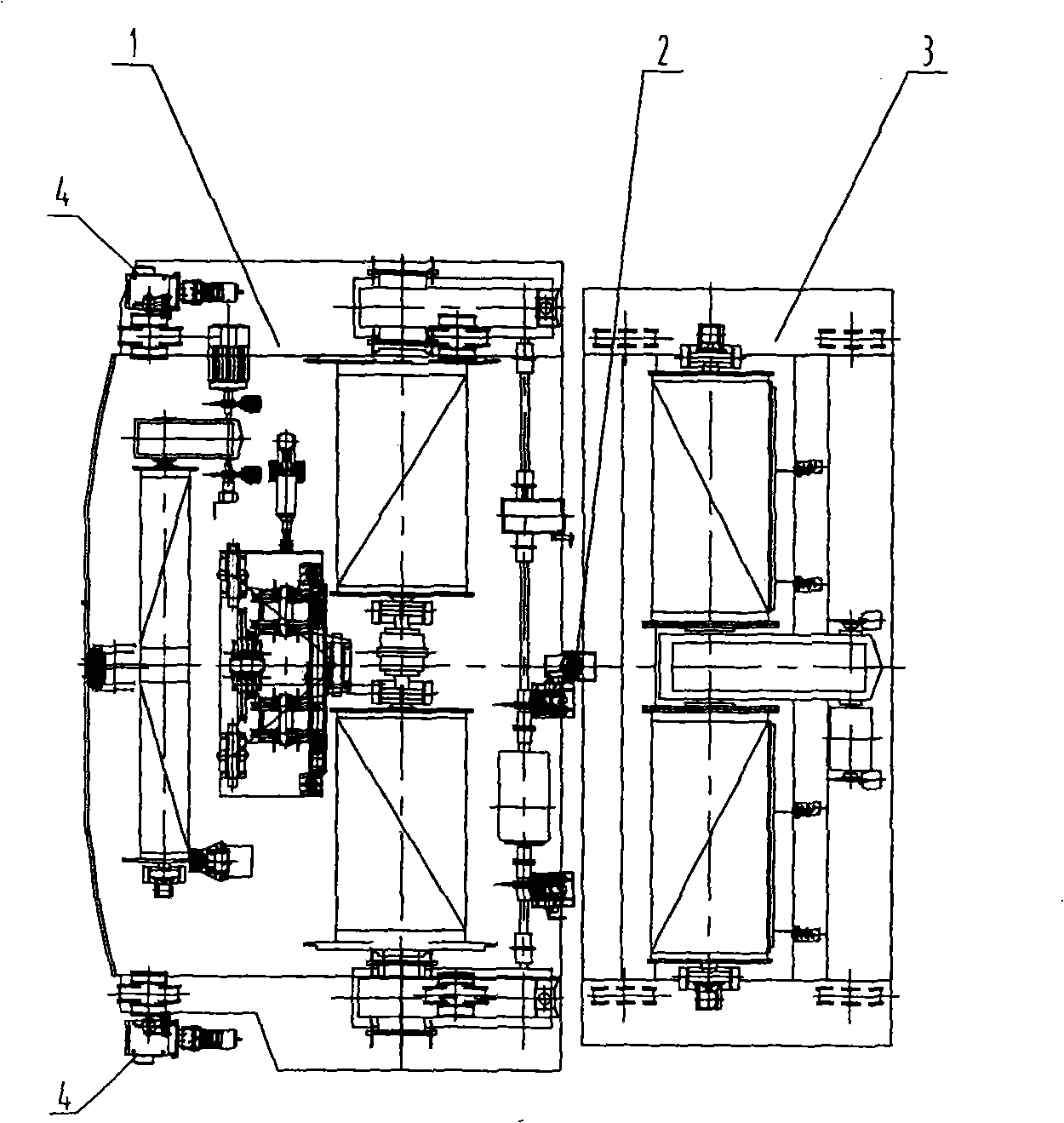

[0011] Such as figure 2 As shown, a synchronization device for double trolleys of a ring crane is composed of a running trolley 1, an installation trolley 3, and a paralleling device 2 connecting the running trolley 1 and the installation trolley 3. The operating trolley 1 is provided with a running driving mechanism 4, and the installation trolley 3 is not provided with a driving mechanism. The running trolley 1 is dragged and installed by the parallel device 2 to install the trolley 3, which not only completely solves the synchronization problem of the two trolleys, but also reduces a set of running driving mechanisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com