Offshore material supply method

A material and unmanned aerial vehicle technology, applied in the field of marine material supply based on multi-rotor drones, can solve the problems of short battery life, low wind resistance, and small carrying capacity, and achieve the goal of increasing motor power and wind resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

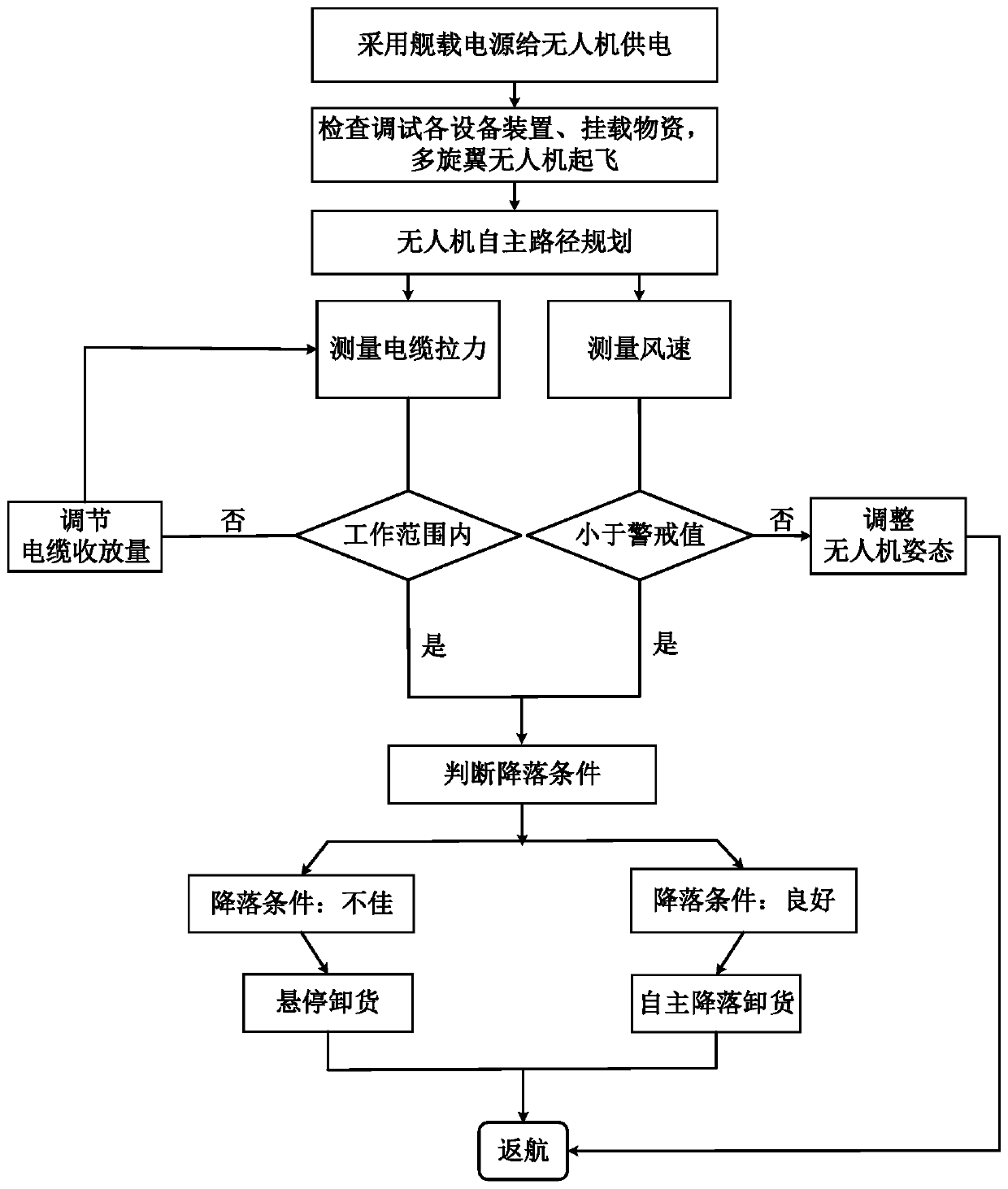

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

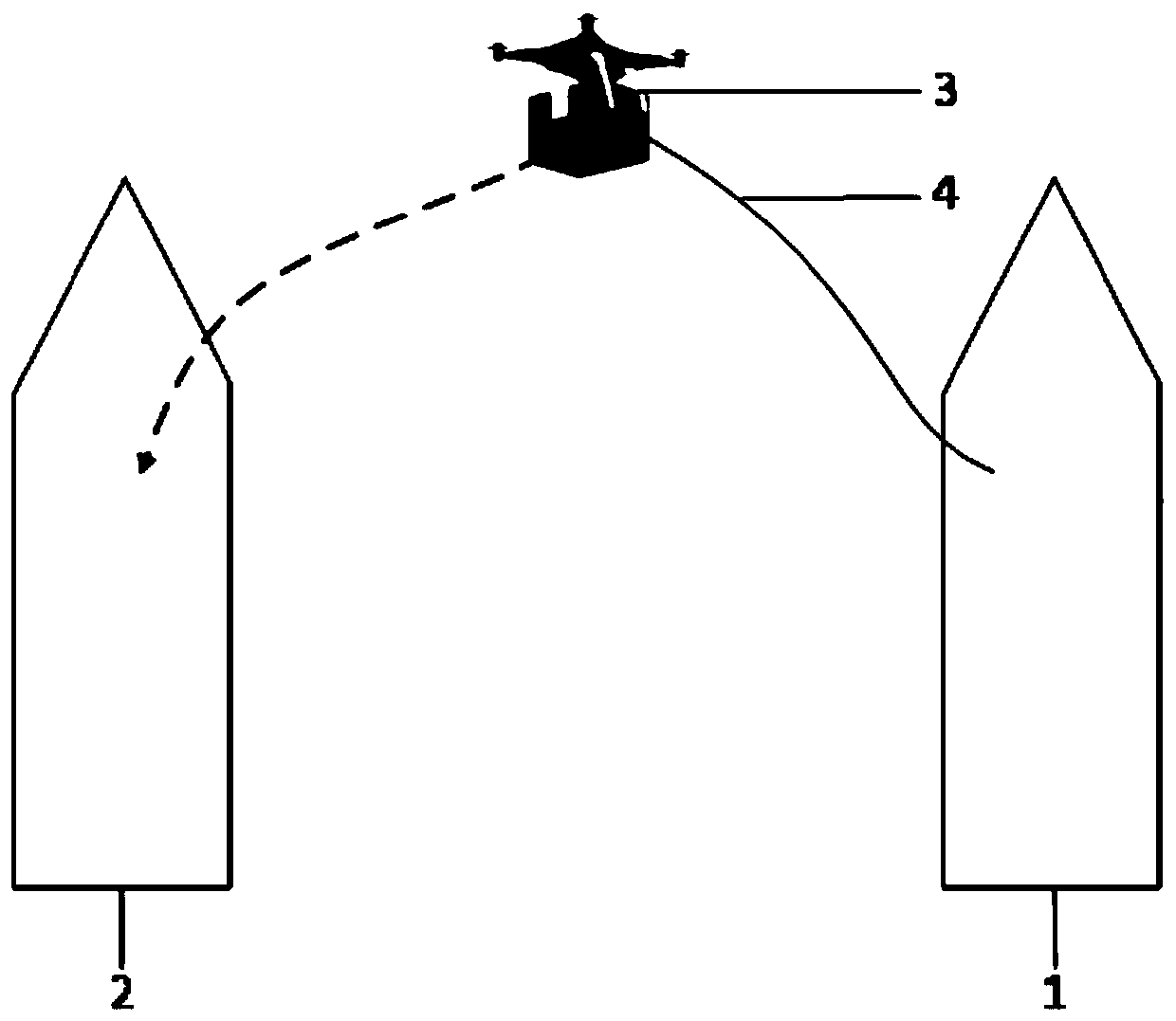

[0025] The system of inter-ship replenishment using drones at sea is divided into three parts: the supply ship carrier platform, the replenished ship replenishment platform, and the UAV platform.

[0026] The shipboard platform of the supply ship includes an integrated control cabinet, a power supply system and a ground station.

[0027] The power supply system includes a power supply device, a power conversion module and a power supply cable. Among them, the power supply equipment converts the AC output from the ship power grid into a stable and reliable high-voltage direct current, and transmits it to the UAV platform through a power supply cable as the main power supply of the UAV; The high-voltage direct current transmitted by the cable is converted into low-voltage direct current to supply power for the UAV and other load equipment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com