Electric motorcycle steel ring and motor casing unit assemblage and its manufacturing method

A technology for electric motorcycles and motor casings, applied in electric components, casings/covers/supports, electrical components, etc. There are problems such as loss, so as to save material costs, facilitate processing and assembly, save labor, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

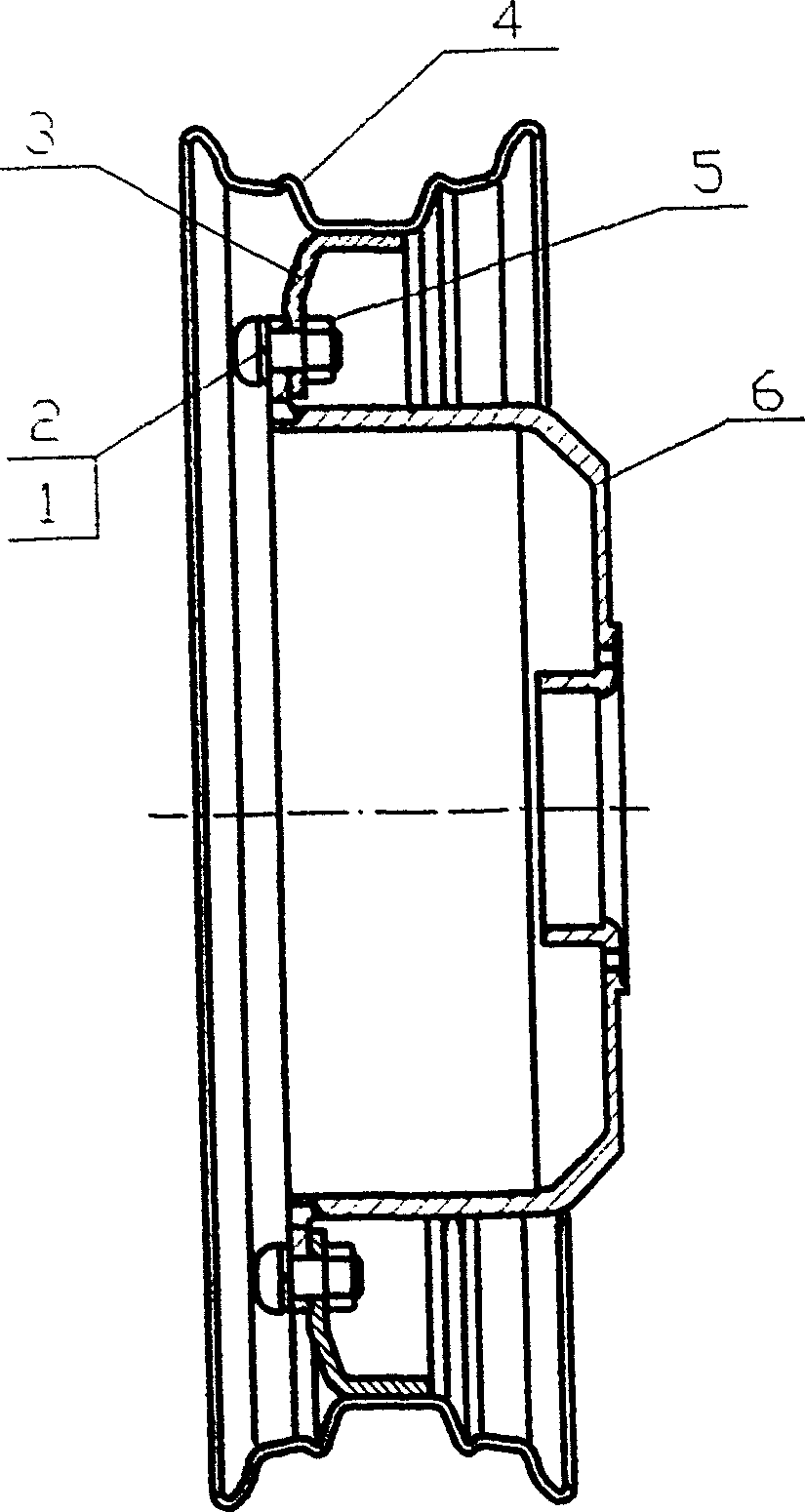

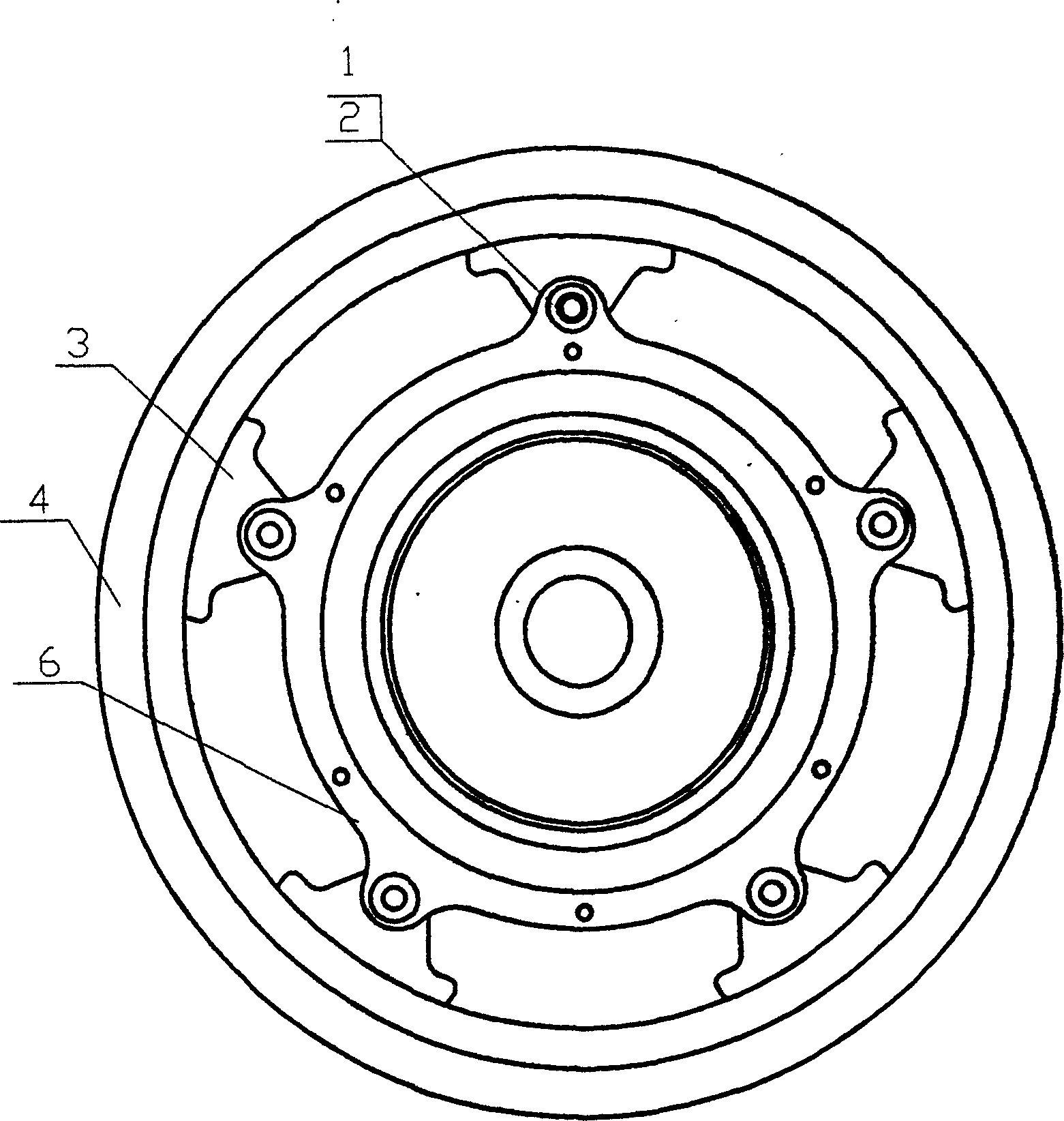

[0012] exist figure 1 , figure 2 Among them, five spoke plates (3) are evenly distributed and welded on the steel ring (4), the motor housing and one end cover are integrated, and the open end of the motor housing (6) has an everted flange, and the spoke plates (3) and the flange of the motor housing (6) are fixed with bolts (1), spring washers (2) and nuts (5). The motor casing (6) is formed by stretching a low-carbon steel plate, and the radial plate (3) is formed by stamping a steel plate. At the open end of the motor housing (6), a bearing support end cover or a brake drum can be installed as required.

[0013] Such as figure 1 , figure 2 As shown, the steel plate is first spun into a steel ring (4), the steel plate is stamped into a spoke plate (3), and then the spoke plate (3) is welded to the inner ring of the steel ring (4), and the motor housing (6 ) The flange plate and the spoke plate (3) are fastened with bolts (1), spring washers (2) and nuts (5), and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com