Annular electric propeller driven by axial magnetic flux motor

A technology of axial magnetic flux and motor drive, applied in the direction of rotary propellers, propulsion components, ship propulsion, etc., can solve the problems of reducing system propulsion efficiency, intermediate transmission loss, and large space occupation, so as to save cabin space, The effect of high reliability and less space in the cabin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

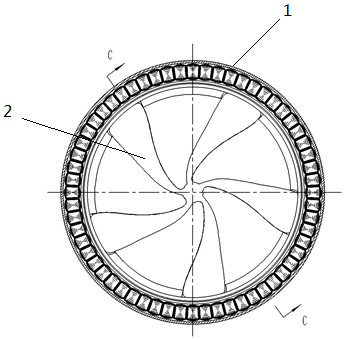

[0035] Embodiment 1: as figure 1 , 4 As shown in and 5, the annular electric propeller of this embodiment is a double-stator single-rotor assembly structure, which mainly includes: a housing, an axial flux motor, a propeller and a bearing assembly.

[0036] The axial flux motor of the present invention adopts an axial flux permanent magnet brushless motor (disc motor). The axial flux motor is different from the ordinary motor. The conductor system is placed radially, and the stator and rotor are disc structures. The motor is composed of a stator assembly, a rotor assembly, a casing, and an end flange. The left and right stator components are respectively fixed on the left and right end face flanges of the motor, and the middle is a single rotor component. The stator assembly of the motor is composed of an axial iron core and a coil, and can also be designed as a coreless structure. The stator assembly is encapsulated with multi-layer sealing and insulating filling protectio...

Embodiment 2

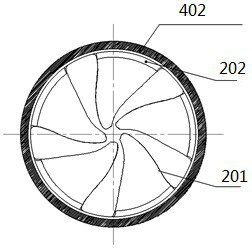

[0048] Example 2: When the power density requirement is not high, the type of single stator and single rotor can be used to reduce power and power density, such as Figure 6 and 7 As shown, the annular electric thruster of this embodiment has a single-stator and single-rotor assembly structure. The difference from Embodiment 1 is that the number of the stator assemblies is set as one group, and the rotor assembly is only driven by a single stator assembly on one side. With single stator and single rotor, the power is reduced and the power density is reduced, but the structure is simple and the cost is low, which is suitable for propellers with low power and low requirements on power density.

Embodiment 3

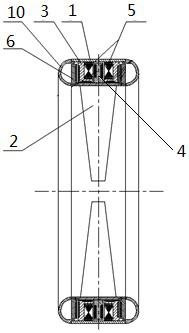

[0049] Embodiment 3: When the power needs to be larger and the diameter remains the same, that is, when the power density needs to be increased, it can be realized by increasing the number of stator assemblies and rotor assemblies, that is, multiple stator assemblies drive multiple rotor assemblies at the same time , multiple rotor assemblies simultaneously drive a propeller. Such as Figure 8 and 9 As shown, the annular electric propeller of this embodiment has a three-stator double-rotor assembly structure. The difference from Embodiments 1 and 2 is that three stator assemblies drive two rotor assemblies, and two rotor assemblies simultaneously drive a propeller.

[0050] The motor adopts a multi-disc structure with three stators and two rotors. The front and rear stator assemblies are respectively fixed on the front and rear end flanges of the motor, and the middle stator assembly is embedded in the housing. There is a rotor assembly in the middle of every two stator asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com