Automatic assembly production line for plastic package motor

A technology for automatic assembly and plastic packaging of motors, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve the problems of not being able to adapt to the motor assembly production process, low degree of automation, and large footprint of the assembly line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and specific embodiments.

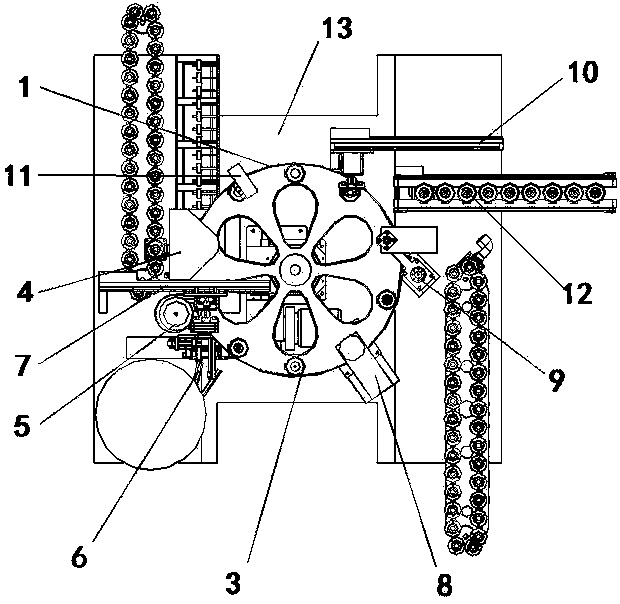

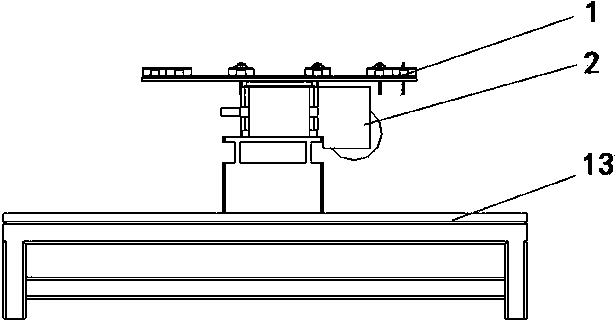

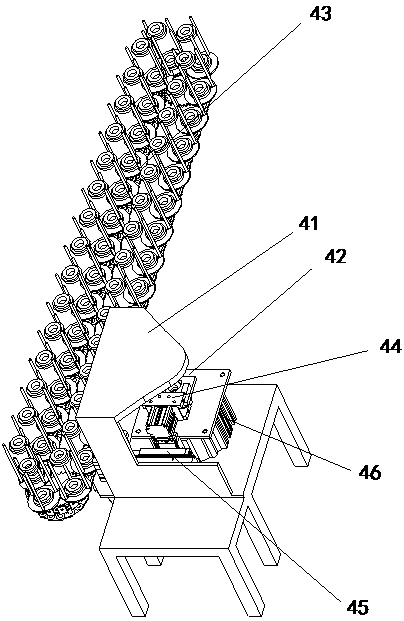

[0029] like Figure 1~2 As shown, the plastic-sealed motor automatic assembly production line of the present invention includes a turntable 1 and a divider 2, and the divider 2 drives the turntable 1 to rotate intermittently, and the rotation period is 7 seconds. The turntable 1 is erected on the divider 2, and is provided with ten stations 3, and each station 3 is manually placed with a stator. The turntable 1 and the divider 2 are arranged in the center of the frame 13 . Frame 13 is welded with square steel, two meters long and two meters wide, in an I-shape, used to place various mechanisms of the automatic assembly production line, and arrange each mechanism as compactly as possible to save floor space. Surrounding the turntable 1, there are safety detection equipment 11 for detecting whether the stator is placed in place, a lower cover press-fitting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com